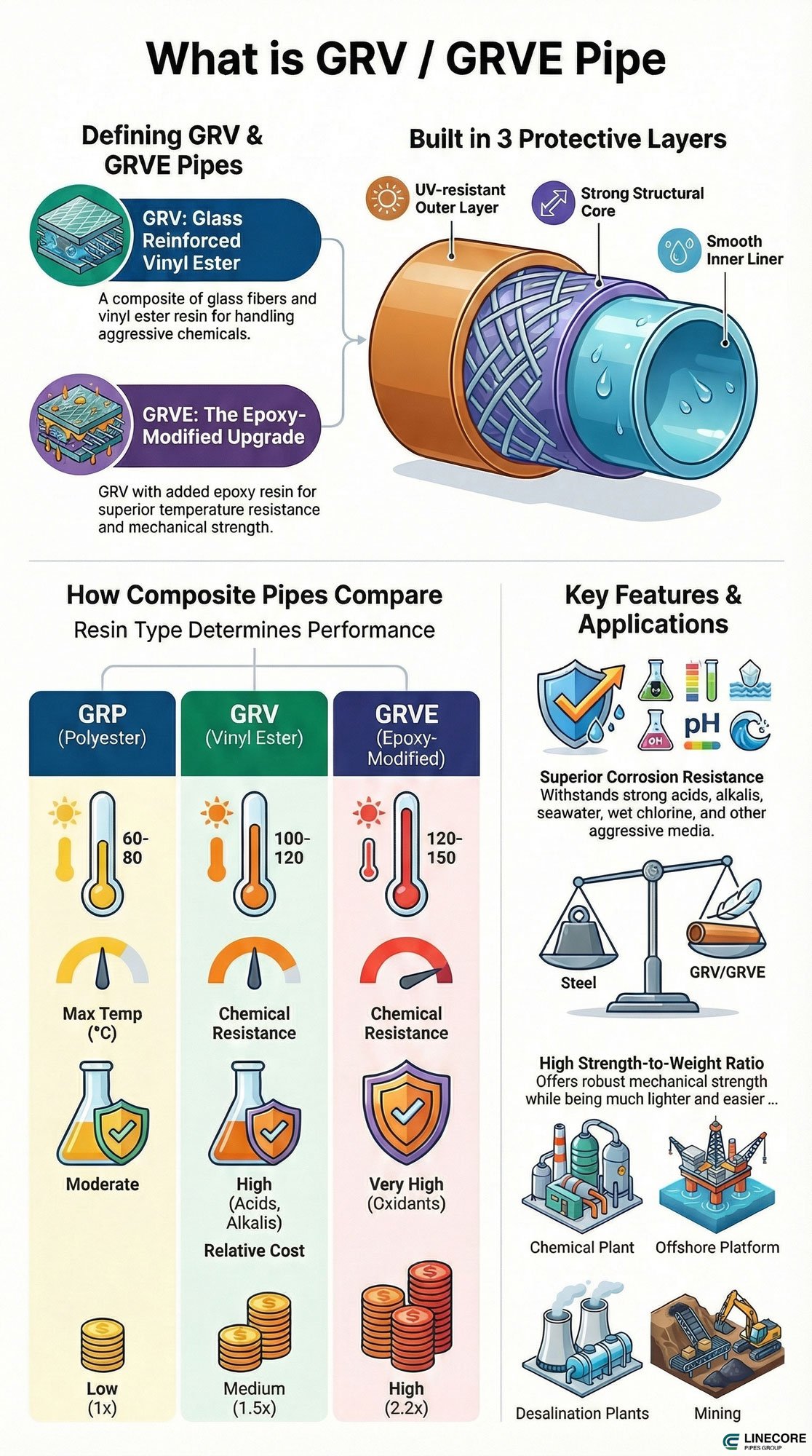

What came next to replace steel and old-fashioned plastic pipe in industrial piping systems? The answer is based on the GRV and GRVE pipes. GRV/GRVE (Glass Reinforced Vinyl Ester or Epoxy) pipes are made of glass fibers and a resin matrix to handle the harshest surrounding conditions for pipelines. Compared to GRP and GRE, these pipes show superior resistance to chemicals like acids and alkalis in various use cases.

This article is a guide to understand what exactly GRV and GRVE are, manufacturing processes, their characteristics, and applications around the world. Stay tuned till the end to get covered by whether resin or knowledge!

GRV Explained: How Have GRV Pipes Changed The Game Of FRP Pipe Family

GRV pipes are made of glass fibers and vinyl ester resin matrix via continuous processes to make such a smooth inner surface for energy reduction. These pipes are formed in a way to handle both pressure and aggressive chemicals.

More Specific Look into Composition: Vinyl Ester & Glass Fibers

- Resin Type: Vinyl Ester resin links epoxy backbone with acrylic ends, then goes through curing for a sturdy matrix that resists aggressive fluids better than basic polyesters.

- Reinforcement: E-glass or ECR-glass rovings add to the pipe high tensile strength with lower weight compared to steel pipes (around 1.8 g/cm³).

These materials improve some characteristics inside the pipes, such as:

- Resistance to acids, alkalis, and solvents

- Works up to 120°C

- Shows low water uptake

- Includes 70-90 MPa tensile strength (MDPI)

How does GRV differ from GRP?

GRP is made of glass fibers and polyester resin, which makes it cheaper, but it can handle less aggressive fluids and should be placed in a more moderate environment. At the same time, GRV with layers of vinyl ester resin resists various harsh chemicals with no corrosion included.

GRVE Explained: What Makes GRVE Superior to GRP, GRE, or GRV

Want to have the leveled-up version of GRV or a pipe having properties of both GRE and GRV? Try installing GRVE pipe for your piping system for a thermally stable and chemically resistant pipeline that lasts over half a century.

What Exactly Is GRVE?

GRVE is a modified version of GRV by adding epoxy resin to its material, which improves temperature resistance and strength under heavy loads. Toughness from GRE and chemical toleration of GRV!

A Deeper Dive Into Materials: Where Epoxy Resin Shines!

The modification adds epoxy groups to the vinyl ester base to improve heat tolerance and mechanical strength, which keeps the excellent fluidity for manufacturing.

- Resistance to strong oxidants, acids, wet chlorine, and aggressive soils (Source: Future Pipe)

- Lower permeation rates in harsh media

That’s Why GRVE Is The Best Option for Highly Aggressive Environments.

These pipes are popularly used in several use cases like chemical processing, effluent pipelines, offshore brines and subsea pipelines, or high-pH sewerage, where alternatives may degrade and fail.

Resin Comparison: GRP vs GRV vs GRE vs GRVE

GRP pipes family covers various applications with their unique characteristics that stem from the resin type of each. Below, we provide a comprehensive table that compares GRP, GRV, GRVE, and GRE pipes based on their final application.

| Type | Resin | Max Temp (°C) | Chemical Resistance | Best For | Relative Cost |

|---|---|---|---|---|---|

| GRP | Polyester | 60-80 | Moderate (mild acids, water) | Water, sewage, general use | Low (1x) |

| GRV | Vinyl Ester | 100-120 | High (strong acids, alkalis) | Chemical plants, wastewater | Medium (1.5x) |

| GRE | Epoxy | 110-150 | High (oils, hydrocarbons) | Oil & gas, high-pressure lines | High (2x) |

| GRVE | Epoxy-Modified Vinyl Ester | 120-150 | Very High (oxidants, aggressive media) | Extreme corrosives, mining, brine | High (2.2x) |

- Summary: Then, choose GRP for general uses, GRE for high temperature and pressure cases, and GRV/GRVE for highly aggressive applications like chemical processing in industrial plants.

GRVE/GRV Pipe Construction and Manufacturing Process: Methods and Initial Techniques

The construction of GRV pipes includes three fundamental layers: inner, structural, and outer layers, each of which helps pipes perform well. This section goes through their manufacturing methods and their specifications.

Layered Composite Structure (Liner, Core, Exterior)

Unlike traditional pipelines, which require extra coatings and linings, GRV pipes themselves include multiple layers of resin and glass fibers that are highly resistant to pressure or corrosion.

- Inner Layer: Smooth and corrosion-free with no degradation or a high range of pumping energy requirements.

- Structural Layer: As noted in ScienceDirect, in many directions (hoop, axial, helical) to add to the strength of pipes under heavy loads.

- Outer Layer: Added resin and additives to resist under UV light and corrosive conditions.

Filament Winding Process: The Most Popular Method for GRV Pipes

The filament winding method makes pipes by wrapping glass fibers around a mandrel to shape the pipes. This method can increase the strength and make it smooth for high flow rates.

Inner Liner Thickness and C-Glass Veil Use

The inner layer thickness can be designed based on the project requirement, and the C-glass veil increases the resistance of pipes against corrosion and structural strength over decades.

- Pro Tip: The ratio of resin and glass fiber composition indicates how strong pipes act under external loads. Scribd highlights that a higher ratio of glass fiber adds to mechanical specs, while the resin helps pipes to resist chemicals.

Technical Specifications of GRV Pipes

In this section, we provide a comprehensive table that includes all specifications of GRV and GRVE pipes. Check the table below to understand how each of these properties determines the final performance of pipes.

| Specification | Range | Notes |

|---|---|---|

| Standard Diameters | 25 mm – 4000 mm | Available in various sizes |

| Available Lengths | 3 m to 12 m | Custom lengths on request |

| Pressure Ratings | Up to 32 bar | Suitable for medium-high pressure systems |

| Stiffness Classes | 2500 – 10000 N/m² | High stiffness for tough applications |

| Temperature Resistance | -40°C to 120°C | Suitable for most environments |

| Wall Thickness | 3 mm to 20 mm | Varies by diameter and use |

| Material Type | Vinyl Ester Resin, Glass Fibers | Common in GRV pipes |

| Tensile Strength | 100 MPa to 300 MPa | Depends on fiber content |

| Elongation at Break | 3% to 5% | Indicates flexibility |

| Impact Resistance | High | Good mechanical shock resistance |

| Flexural Strength | 150 MPa to 250 MPa | Resists bending |

| Corrosion Resistance | High | Withstands chemicals and seawater |

| Chemical Resistance | Excellent | Resists most chemicals |

| UV Resistance | High | UV protection with C-glass veil |

| Standard Lengths | 3 m to 12 m | Customizable |

| Bending Radius | 5 times diameter | Minimum bend radius |

| Weight per Meter | 5 kg to 35 kg | Varies with size and thickness |

| Expansion Coefficient | 0.05 mm/m°C | Linear thermal expansion |

| Maximum Operating Pressure | Up to 32 bar | Maximum pressure |

| Pressure Rating for Bursting | 50 bar | Max pressure before burst |

| Fire Resistance | Moderate to High, Can be higher by adding additives | Flame-retardant |

| Installation Method | Threaded, Flanged, Adhesive | Multiple installation options in various site conditions |

| Service Life Expectancy | 25 to 50 years | Estimated life in standard conditions |

GRV Pipe Fittings & Accessories

GRV pipes are connected via various fittings and jointing pieces to make smooth and leak-free connections. These fittings are made from the same material as the pipes for consistent performance.

Types of Fittings

Common GRV pipe fittings include:

- Elbows: Used to change the direction of the pipe.

- Reducers: To connect pipes of different sizes.

- Tees: For splitting the pipe into multiple directions.

- Flanges: For joining pipes together.

- End Caps: To seal the ends of the pipes.

Material Consistency with Pipes

The fittings are made with the same vinyl ester resin and glass fibers as the pipes, making sure they are equally strong and corrosion-resistant.

Custom Fittings for Complex Systems

For unique projects, custom fittings can be made to fit specific needs, especially in systems with special requirements like high pressure or extreme temperatures.

The Performance Features of GRV/GRVE Pipes

GRV and GRVE pipes work great in challenging places. People enjoy them because they help resist corrosion, especially when working with acids, bases, or salty water. Their combination of vinyl ester resin and glass fiber makes a great protection against chemicals.

- Resistant to Corrosion: These pipes can take a lot of substances, like acids, alkalis, and seawater, without any problems. Great for cleaning up chemicals, working in the ocean, or cleaning up sewage.

- Ratio of Strength to Weight: They have a lot of strength without being as heavy as metal pipes, so they’re easier to move and set up, but they’re still quite reliable.

- Low thermal conductivity: These pipes keep temperatures steady inside because they don’t transfer heat well. This is perfect for setups that need consistent management. (Source: ResearchGate)

- Smooth Inside Surface: The smooth insides of these things reduce drag, which means less pressure drop and smoother fluid flow.

- Longevity and Life-Cycle Cost: They are built to last and don’t need much maintenance, which saves time and money. Unlike steel pipes, GRV pipes need no extra coating and lining, which makes them cost-effective.

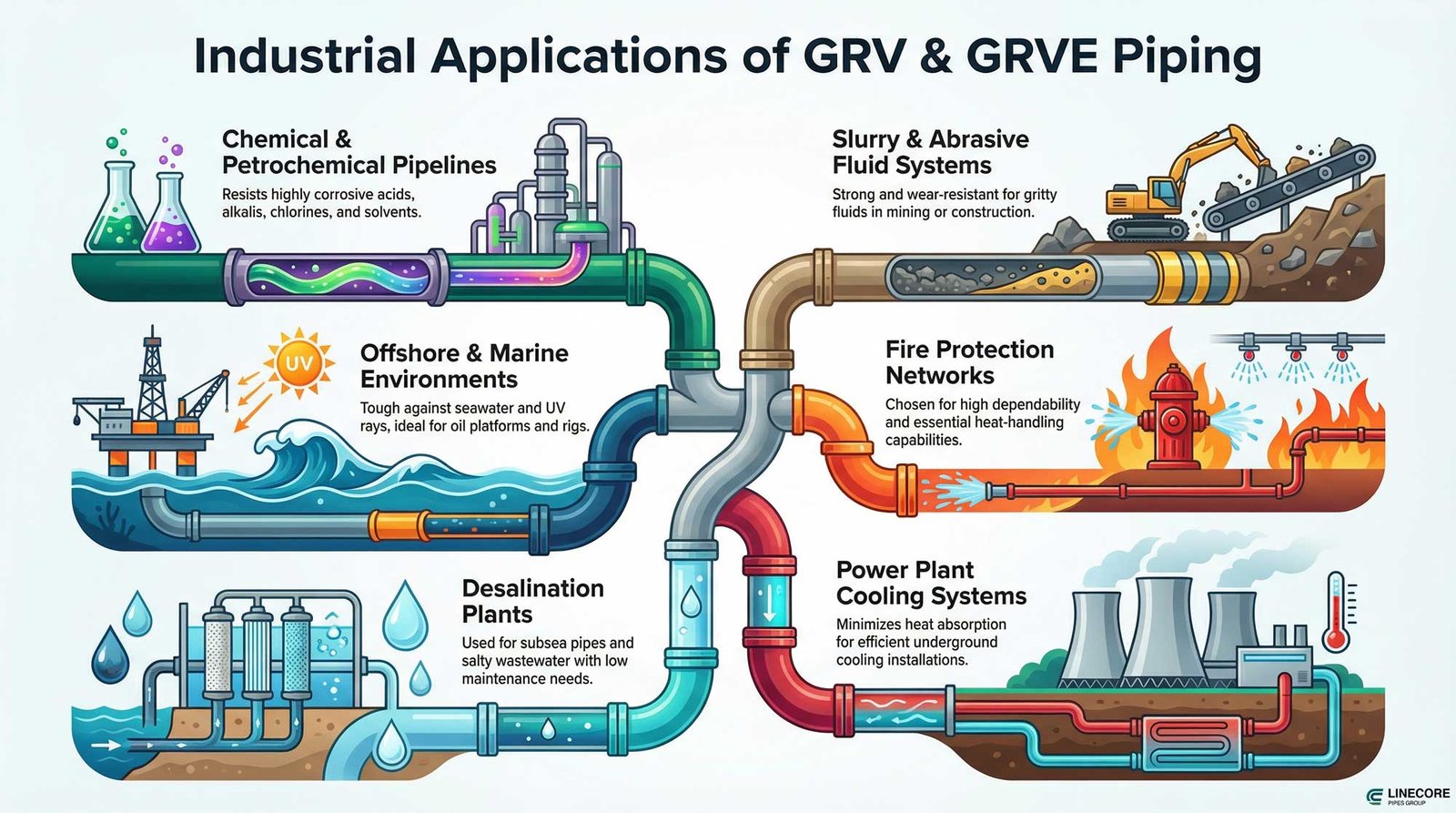

Applications of GRV / GRVE Pipes

GRV and GRVE are used in various use cases due to their flexible design and corrosion resistance. In fact, their resistance is under highly corrosive soils or saline conditions.

1. Chemical and Petrochemical Pipelines

Best option for the chemical processing and industrial uses with the highest rate of corrosion and chemical resistance against acids, alkalis, chlorines, and solvents.

2. Offshore and Marine Environments

With seawater and UV toughness, these pipes are key for ocean gigs like drilling rigs and oil platforms.

3. Desalination Plants

In the saline and marine environments, GRV and GRVE pipes are used in several stages of desalination plants, such as subsea pipes or salty wastewater, with less maintenance requirements over the decades.

4. Power Plant Cooling Systems

GRV pipes are used for cooling systems with underground installations, which require pipes with the least heat absorption so as not to waste the chillers’ effort.

5. Fire Protection Networks

They show up in fire systems too, where dependability and heat-handling are must-haves.

6. Slurry and Abrasive Fluid Systems

GRV/GRVE pipes tackle slurries and gritty fluids thanks to their strength and wear resistance, ideal for mining or building work.

Limitations & Considerations: Advantages and Disadvantages Included

GRV pipes, like other pipelines, may show some flaws during their lifetime, such as limitations of pressure, higher initial costs, or the need for expansion joints. Here are the core benefits and limitations of GRV pipes:

- Pressure and temperature limits

- Higher cost than GRP and metal pipes

- Requires skilled installation

- Thermal expansion needs expansion joints

These factors must be considered for specific applications.

| Advantages | Disadvantages |

|---|---|

| Corrosion Resistance: Withstands acids, alkalis, and seawater. | Higher Initial Cost compared to metal pipes. |

| Lightweight: Easier to handle and install. | Temperature Limitations: Limited to specific ranges. |

| Durable: Long lifespan and low maintenance. | Installation Needs Expertise. |

| Strength-to-Weight Ratio: High strength, low weight. | Pressure Limitations for very high-pressure systems. |

| Low Maintenance: Minimal upkeep required. | Brittleness: Susceptible to high impact damage. |

| Smooth Surface: Reduces pressure loss. | Custom Fittings may add cost. |

Thus, GRV pipes are one of the best solutions for modern infrastructures like industrial or desalination systems.

Your Trusted Partner for GRV Piping Systems: from Designs to Further Supports!

Do you need high-quality GRV/GRVE pipes that can handle the extreme conditions? Contact LineCore Pipes Group, the GrandPipe Company’s official representative. We produce high-quality composite pipe that is perfect for your specific business needs. Imagine long-term performance in chemical plants, wastewater operations, and salty marine installations. Are you ready to level up? For prices, specs, and expert assistance, contact info@pipelinecoregroup.com right now!

FAQs

1- What are GRV pipes made of?

GRV pipes are made of glass fibers, vinyl ester resin, and additives to make them superior in the high-risk sectors like chemical processing.

2- What industries use GRV pipes?

GRV pipes are used in chemical processing, petrochemical pipelines, desalination plants, wastewater treatment, offshore platforms, and fire protection systems.

3- How are GRV pipes installed?

It depends on the site condition and use case, for instance, in cooling systems, pipes are installed underground and require special jointing methods like flanges or butt and wrap.

about

The Author

Farshid Tavakoli is a seasoned professional in engineering and international trade. Holding degrees in Electrical Engineering, Mechatronics, and a Doctorate in Business Administration (DBA) from the University of Lyon, he also has a strong background in industrial automation and production line technologies.

For over 17 years, he has led an international trading company, gaining deep expertise in commercial solutions tailored to industrial needs. With more than 8 years of active involvement in infrastructure development, he specializes in the supply of electromechanical equipment for water and wastewater treatment plants and transfer projects.

Together with comapny expert team, he now provides consultancy and integrated solutions for sourcing and implementing complex infrastructure projects across the region.