Unlike traditional metal pipes, Baker Hughes highlights that composite pipes can reduce maintenance costs by up to 80%. But what is the GRE pipe in this case? GRE pipes are a composite of glass fibers and epoxy resin that improve both strength and durability in aggressive conditions. That’s why GRE pipes are a top choice for modern applications such as oil and gas and marine.

This post guides engineers and contractors to find helpful information on GRE pipes, their specific characteristics, and the standards that enable GRE pipes to be aligned with every piping system worldwide.

Definition of GRE Pipes

Glass Reinforced Epoxy (GRE) pipes are a complex blend of E-glass fibers and epoxy resin used in various piping systems.

GRE Pipe Composition

The creation of GRE pipe stems from two central components:

- E-glass Fibers: Added to make such hoop and axial strength in structural design.

- Epoxy Resin: Unlike other resin types, it can improve the resistance to chemicals and high temperatures in oil and gas pipelines.

These layers go toward shaping a durable, corrosion-resistant pipe that can withstand harsh conditions.

What Properties make GRE Pipes stand in Aggressive Soils?

GRE pipes are known for their great resistance, coming from the choice of resin type. These four central characteristics show why GRE pipes are that durable:

| Property | Benefit | Applications |

|---|---|---|

| Corrosion Resistance | Longer lifespan, low maintenance | Chemical, marine, wastewater |

| Pressure Resistance | Handles high-pressure fluids | Oil, gas, water pipelines |

| Heat Resistance | Maintains strength at high temps | High-temp transport, geothermal |

| Lightweight | Easier handling, cost savings | Remote areas, offshore platforms |

How GRE Differs from GRP, GRV and FRP

GRE (Glass Reinforced Epoxy) pipes, GRP (Glass Reinforced Polyester) pipes, and GRV (Glass Reinforced Vinyl Ester) pipes are all core members of the FRP family, which are popularly used in piping systems, while the resin type used in each provides different properties for various industrial use cases.

GRE vs GRP vs GRV: Differences in Resin Types and Performance

Each of these three composite pipes uses a resin type that can change the resistance to chemicals or temperature in whatever further components, check the table below to compare them:

| Property | GRE (Glass Reinforced Epoxy) | GRP (Glass Reinforced Polyester) | GRV (Glass Reinforced Vinylester) |

|---|---|---|---|

| Resin Type | Epoxy Resin | Polyester Resin | Vinylester Resin |

| Strength | High mechanical strength and rigidity | Moderate strength, suitable for lower pressure | High strength, better than GRP but less than GRE |

| Temperature Tolerance | Up to 120°C (248°F) | Up to 75°C (167°F) | Up to 90°C (194°F) |

| Chemical Resistance | Excellent, best for aggressive chemicals | Good, but less resistant than GRE | Very good, better than GRP but not as good as GRE |

| Flexibility | Low flexibility, rigid | Moderate flexibility | Moderate flexibility |

| Applications | Oil & Gas, Marine, Chemical Processing, High-Pressure Systems | Water Treatment, Sewage, Irrigation | Chemical processing, water systems, industrial piping |

| Corrosion Resistance | Superior, ideal for harsh environments | Good, especially in mild conditions | Excellent, better than GRP in many applications |

In summary, if you’re looking for temperature resistance, choose GRE; for higher chemical resistance, GRV pipe can handle acids and alkalis, and for general use cases, GRP would be a moderate yet cost-effective choice.

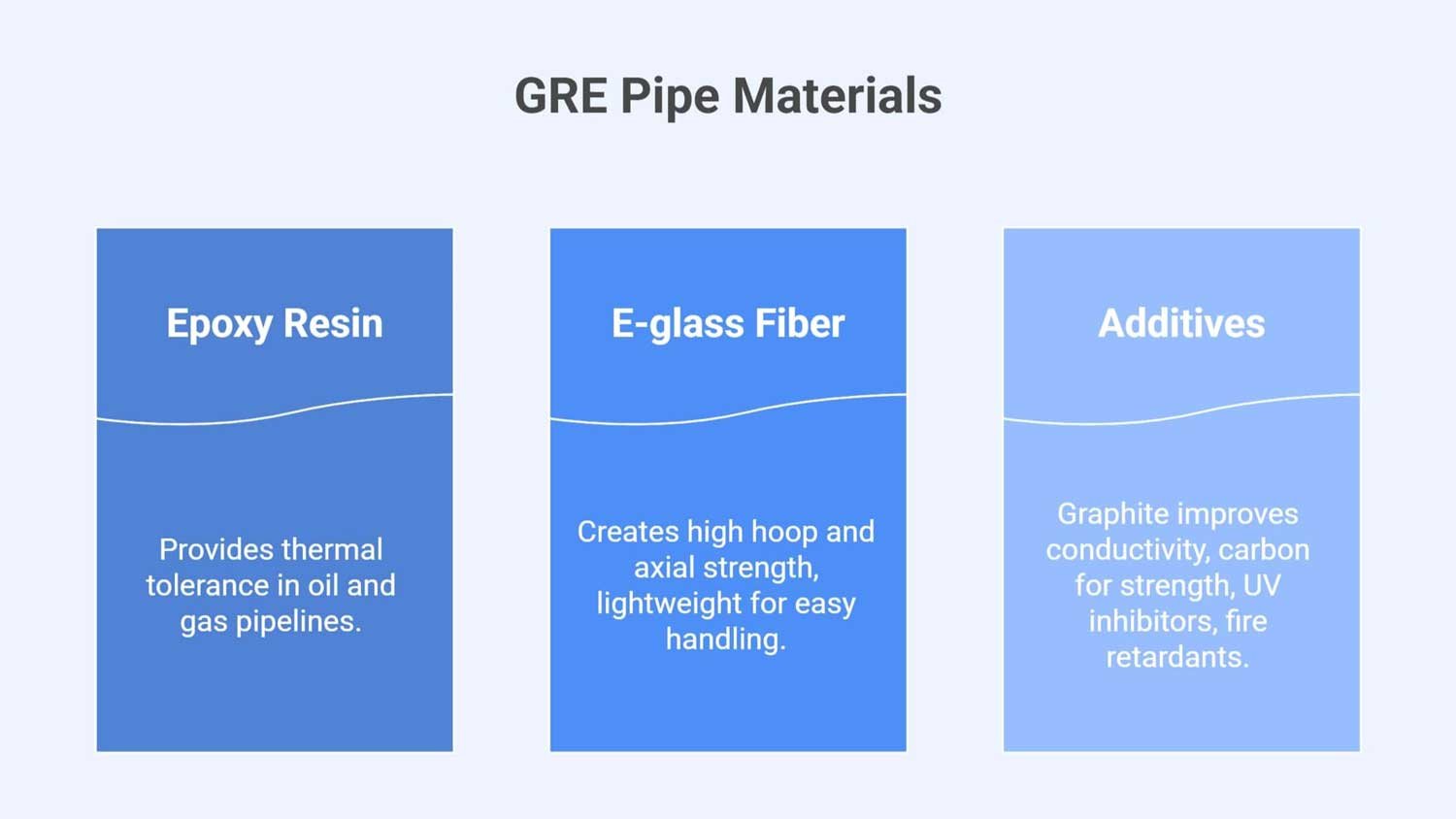

What Materials Are Used in GRE Pipes?

GRE pipes are made of a highly resistant combination of materials such as glass fibers and epoxy resin matrix. Let’s see how each improves GRE’s properties.

- Epoxy Resin: This resin type in GRE pipe shows the thermal tolerance in oil and gas pipelines, where the cost of repairs and risk of aggressive chemicals are conventionally high. (Source: FuturePipe)

- E-glass Fiber: These fibers are used to create such high hoop and axial strength to handle both internal and external pressure, while their lightweight can help surpass metal pipes for easier handling and installation.

- Additives: Graphite is added to improve electrical conductivity, carbon for strength, UV inhibitors for aboveground pipelines, and fire retardants to decrease the risk of flames.

Manufacturing Process of GRE Pipes

GRE pipes are manufactured by the filament winding process and layering to undergo curing and further testing.

Filament Winding Process of GRE Pipes

At the beginning of this process, glass fibers are coated with epoxy resin, which is called impregnation. Then, they go through winding around a mandrel to shape such a pipe-like structure in helical patterns.

How Many Layers does GRE Pipe Get during the Manufacturing Process?

There are three main layers explained below clearly in the GRE pipes.

- Inner Liner: Provides resistance to corrosive chemicals.

- Structural Layer: Adds strength and pressure resistance.

- External Coating: Shields the pipe from environmental wear and tear.

Curing and Post-Curing for Hardening

Once pipes are coated and shaped, it’s time to get hardened by heating pads. (Source: Scribd) While post-curing refers to a process that can improve the resistance under heavy loads and high-pressure systems, it is also aligned with global standards.

Mechanical and Physical Properties of GRE Pipes

As we mentioned in the last sections, GRE pipes are such strong pipes for complex conditions due to their perfect mechanical and physical characteristics.

Axial and Hoop Strength

The design and layering of GRE pipes help them to resist both tension and internal pressure with no cracks, deformation, or expansion.

Elastic Modulus and Surge Pressure Resistance

This mainly comes from the flexible nature of composite pipes, which GRE pipes can absorb stress with no damage.

Thermal Expansion and Conductivity

As noted in ScienceDirect, GRE pipes have a low rate of thermal expansion and can be electrically conductive with additives in use cases where the temperature of the fluids is high or should be kept stable.

How Does GRE Pipe Benefit from Its Features and Performance?

The GRE pipe includes several features that show how this pipeline can save a project. Let’s check out why the GRE pipe is the top choice over its alternatives.

High Strength-To-Weight Ratio Coming from The Lightweight

Due to the composite material of GRE pipes, they’re lighter than traditional pipelines and can be installed easily in hard-to-access sites.

Corrosion Resistance: A Superior Case of Epoxy Resin

GRE pipes contain a perfect performance in corrosive and harsh environments due to their coating and a protective internal surface layer of epoxy resin, while metal pipe usually fails in the same situation.

The Chance of Reduction in Pumping Energy Requirements in GRE Piping Systems

The smooth inner surface of GRE pipes provides such an opportunity to the road of energy efficiency via increasing the flow rate, while saving the pumping energy.

Built-in Fire Resistance for Safety

The manufacturer can add an extra layer to GRE pipe to increase the fire resistance for those who are seeking strong and durable pipes for oil and gas piping systems.

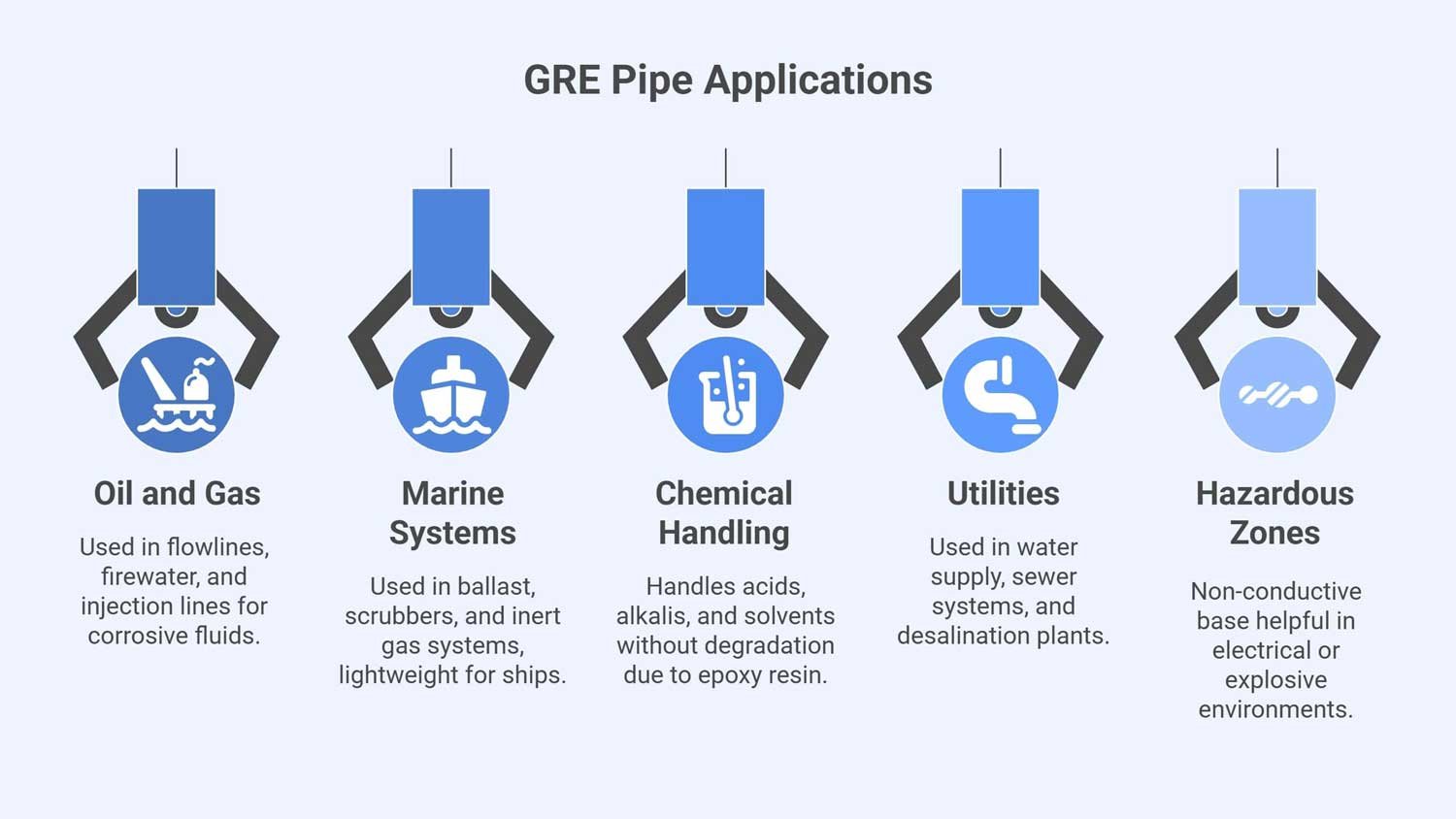

Where GRE Pipes Are Used: From Oil and Gas Pipelines to Utilities and Infrastructure

GRE pipes are used across several industrial use cases due to their excellent performance under harsh conditions. Here are some of the most used ones:

- Oil and Gas Pipelines: GRE pipes are used in flowlines, firewater, and injection lines to handle chemical and corrosive fluids.

- Marine and Offshore Systems: In ballast, scrubbers, and inert gas systems that require such pipes can withstand seawater, while due to their lightweight, they can reduce the overall weight in ships.

- Industrial and Chemical Handling: GRE pipes can handle acids, alkalis, and other solvents with no degradation with their epoxy resin layers.

- Utilities and Infrastructure: GRE pipe can be used in general use cases like water supply, sewer systems, and desalination plants, though GRP can be a more cost-effective choice in these cases.

- Electrical and Hazardous Zones: The non-conductive base of GRE pipes can be helpful when it comes to electrical or explosive environments.

Jointing and Installation Overview: the case of GRE pipe

GRE pipes include such jointing and installation methods to be aligned with various site situations. Below, a brief explanation of each is available.

Joint Types of GRE Pipes

GRP pipes are connected via different methods such as adhesive-bonded, mechanical couplings, or flanged joints that are up to the size, system’s pressure rate, or accessibility of the site.

Installation Design Considerations

GRE pipes can be installed in both under- and above-ground installations. What Is Piping Highlights that in underground ones, by trench alignment and right bedding, while in aboveground ones, anchoring would make the final structure reliable enough.

How to Manage the Risk of Stress and Expansion?

Use expansion joints to control the risk of thermal damage. Remember, the accuracy in anchoring can reach safe and long-term installation.

Standards and Certifications for GRE Pipes

GRE pipes are designed and manufactured according to globally recognized standards to ensure quality, safety, and performance.

International Standards

ASTM (American Society for Testing and Materials): Defines test methods and specifications for fiberglass-reinforced piping systems.

ISO (International Organization for Standardization): Covers design, manufacturing, and qualification of GRE piping systems (notably ISO 14692).

AWWA (American Water Works Association): Can create standards for pressure and non-pressure fiberglass pipes that are used in water supply systems.

API (American Petroleum Institute): Establishes performance standards for GRE pipes used in the oil and gas industries.

Marine Certifications

For marine applications, GRE pipes must comply with SOLAS and IMO safety and fire-resistance regulations.

Pros and Cons of GRE Pipe

As each material has its unique advantages, they can cause some trouble for either general or specific use cases. Check the table below for the pros and cons of GRE pipes:

| Pros | Cons |

|---|---|

| Corrosion and Chemical Resistance: Ideal for harsh environments, resistant to corrosion and chemicals. | Higher Initial Cost: More expensive upfront compared to steel or GRP pipes. |

| Low Maintenance: Requires minimal upkeep, leading to long-term savings. | Skilled Installation: Needs trained professionals for proper installation. |

| High Flow Efficiency: Smooth internal surface reduces friction, improving flow. | Rigid Design: Less flexible, not suitable for complex curves. |

| Thermal Stability: Performs well in high-temperature applications. | – |

When Should We Choose GRE Pipe Over Other Pipe Options?

Choose GRE pipe when the project demands thermal stability, corrosion resistance, and lightweight yet strength against both internal and external pressure.

Choose a GRE pipe when your project matters more than just a decade or two. Although the initial costs of composite pipes are generally high, they last over 50 years in certain conditions.

Your Trusted GRE Pipe Supplier in the GCC and Africa

Whether you’re an engineer, a project manager, or a contractor struggling to find a reliable yet certified GRE pipe supplier, Line Core Pipe Group is a leader aiding you in achieving a piping system aligned to your project demands across the GCC and Africa.

With a strong experience in oil and gas, marine, infrastructure, and industrial projects, we provide you with:

- Internationally verified GRE pipe systems

- Customized pipelines to your own project’s pressure, temperature, size, and installation requirements

- After-sales support and technical recommendations were added to the fast and safe delivery

Contact expert consultants in Line Core Pipe Group today to design a detailed pipeline based on your project needs. Stay tuned!

Conclusion

Now we’ve got to the last station, GRE pipes are such a composite pipe that makes decisions easier in high-pressure and corrosive sites. GRE pipes can handle aggressive chemicals with no degradation. Despite the initial costs, GRE pipes are cost-effective from an overall perspective through their long-lasting lifespan and low maintenance requirements. Choose GRE pipes in oil and gas, marine, or chemical processing with confidence.

FAQs

1- What is a GRE pipe?

GRE pipes are composite pipes made from a combination of E-glass fibers and epoxy resin that improve both strength and durability in aggressive conditions.

2- How does the GRE pipe differ from GRP and FRP?

GRE pipes use epoxy resin, which improves the resistance to chemicals and high temperatures in oil and gas pipelines. This makes them different from GRP pipes (which use polyester resin) and FRP pipes (which can use different types of resin or fibers).

3- How long do GRE pipes last?

GRE pipes can last over 50 years under certain conditions. Although their initial costs are high, the overall cost is low due to the durability and low need for maintenance.

about

The Author

Farshid Tavakoli is a seasoned professional in engineering and international trade. Holding degrees in Electrical Engineering, Mechatronics, and a Doctorate in Business Administration (DBA) from the University of Lyon, he also has a strong background in industrial automation and production line technologies.

For over 17 years, he has led an international trading company, gaining deep expertise in commercial solutions tailored to industrial needs. With more than 8 years of active involvement in infrastructure development, he specializes in the supply of electromechanical equipment for water and wastewater treatment plants and transfer projects.

Together with comapny expert team, he now provides consultancy and integrated solutions for sourcing and implementing complex infrastructure projects across the region.