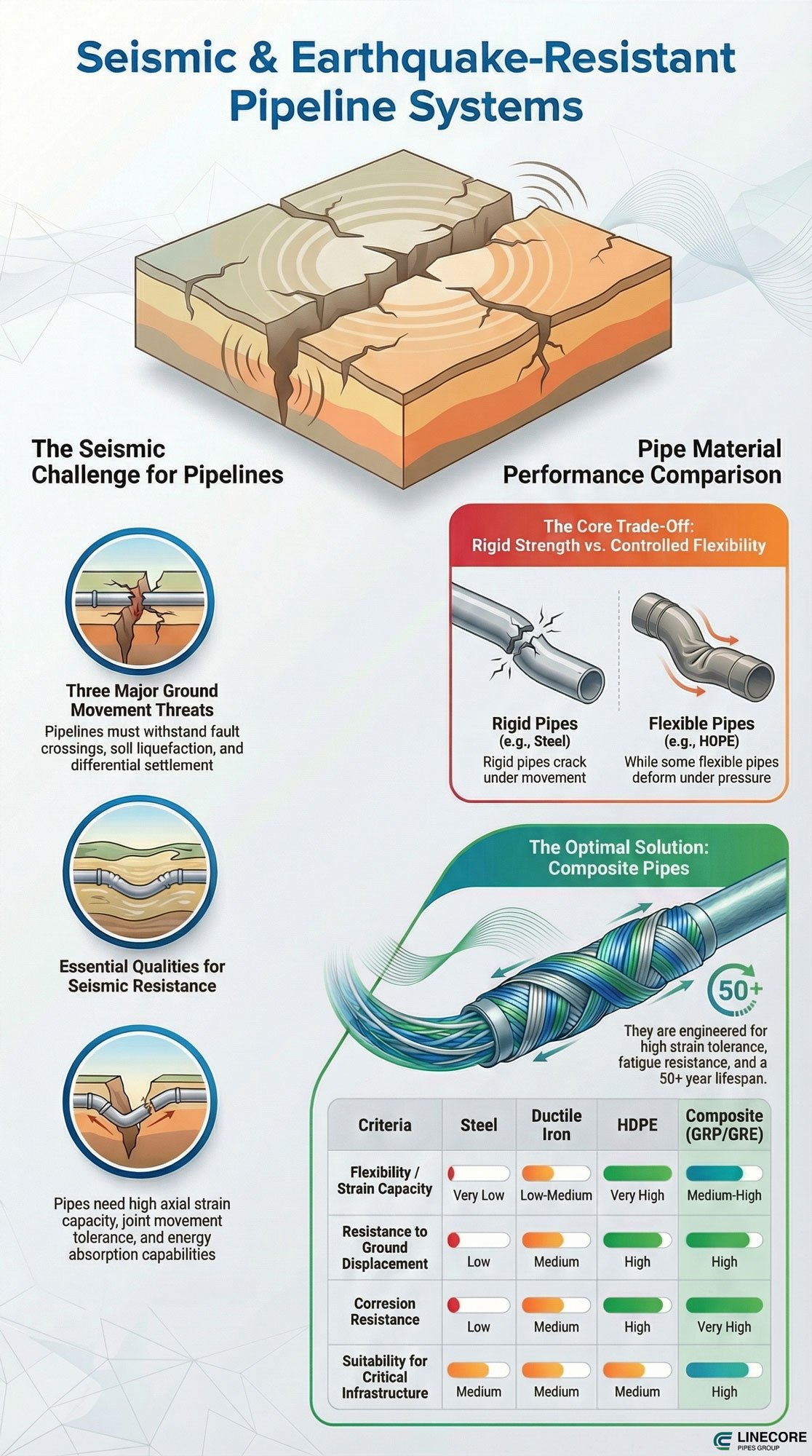

Unlike what many people believe, damage from earthquakes to both underground and above-ground pipelines can be seen. In seismic zones with high vibration risk, scandals like joint separation, cracks, rupture, and stresses on bending are happening in the case of soil liquefaction and ground displacements in the long term.

In the past, strong pipes like metal ones were the best choices, while nowadays, composite pipes that provide strength, flexibility, and resistance to environmental damage factors are modern solutions to piping systems.

What Makes a Pipeline Earthquake-Resistant?

Earthquakes require such a pipeline with the ability to absorb and adapt to the vibrations these seismic zones produce. They’re not only strong enough under external loads and stress, but also are flexible enough to resist soil liquefaction and replacements.

What’s Important in Earthquake-Resistant Pipelines?

There are three main points that shape the base of the earthquake-resistant pipelines, including movement tolerance, absorption capability, and capacity of axial strain.

- Axial Strain Capacity: This aspect is for the way pipes stretch or do not deform under the forces of seismic zones. Under the ground displacement with a high risk of deformation and cracks, this case helps the pipe to resist.

- Joint Deflection and Movement Tolerance: That’s where steel pipes fail, due to their low tolerance to flex, move, and adjust themselves in soil movements with no leakage included.

- Energy Absorption Capability: Seismic zones with their high risk of vibration or stress require high energy absorption properties in the final pipelines.

How Earthquake-Resistant Myths Turned into Actual Seismic-Resistant Design?

There’s no pipeline that can completely beat the harsh conditions of earthquake zones. In fact, the final aim is to reduce the impacts of seismic forces, while changes in design can improve the resilience of whole systems under such events. This works when pipes show no deformation or cracks under their flexing and bending operations.

What Should You Consider When Designing Pipes for Earthquake Zones?

To ensure that the chosen pipeline designed for seismic zones works well, several considerations exist that pave the way. Here are the most crucial ones:

Ground Movement Types

Ground movements can happen in some horrible ways, each resulting in specific dilemmas, some of which we bring below. Check them all.

1. Fault Crossing

It happens when pipes come into contact with lines by mistake, and it’s needed to move pipes in the most moderate way without causing cracks. This means that engineers must be careful about both the design of pipes and their joints.

2. Liquefaction

The case of saturated and weak soils, which include a lack of density, is common ground to move and cause liquefaction (meaning the liquefied soil). Pipelines must be designed in a way that resists such a happening with reliable installation methods. (Source: ResearchGate)

3. Differential Settlement

Unequal settlement of the ground may cause uneven ground under the pipelines and ruin the whole backfilling thing. Then, pipes must be designed in a way to correct these misalignments.

How Will Pipes Behave beneath Compression or Rotations?

Under the axial tensions caused by seismic conditions, pipes may stretch and get compressed. This means dry and highly strength pipes like steel ones may crack, while composite pipes with their exceptional design can withstand without rupture.

Also, they show bend and rotation when the ground’s moving, which only pipes with high flexibility and strength will last without any changes.

What Are Effective Aspects Of Each Piping Systems Making Them Earthquake Resistance?

There are many impactful actions in piping systems that must be aligned with the seismic conditions. Check the table below to understand how they influence the final system.

| # | Consideration | Value | Purpose |

|---|---|---|---|

| 1 | Flexible Joints | Joint movement tolerance: Up to 10-15° | Reduce stress and prevent leaks during ground movement. |

| 2 | Pipe Material Modulus | Modulus of elasticity: 20-40 GPa (for composite pipes) | Balance rigidity and flexibility to withstand seismic forces. |

| 3 | Installation & Trench Design | Trench depth: 1-3 meters, flexible bedding material | Minimize stress and allow for movement with ground shifts. |

Pipe Materials Used in Seismic Zones

Once you understand what a seismic-resistant pipe is, it’s time to get to know its types and how each pipeline suits this condition or not. This section shows how the strength of steel and ductile iron pipe, the flexibility of PVC, the lightweight of HDPE, and all these benefits are in composite pipes.

Steel Pipes: Strong under Heavy Loads and Stress

Steel pipes are used in multiple applications due to their perfect strength in hard-to-access situations. They were top choices in past decades for high-pressure lines, while today their rigidness and low tolerance of strains make them fail in ground displacements. Their important features:

- Welded Joints: Steel pipes are connected via welded joints, with structural reliance that can resist the probable ground movements.

- Differential Settlement: Misalignment in the ground with high stress risk requires such integrity that steel pipes cannot handle it.

- Fault Displacement: Whether in horizontal or vertical directions, shifts in the ground can cause disconnections in the joints.

Corrosion Protective Layer

Steel pipes cannot resist corrosive soils without an extra protective layer, both inner and outer layers.

Final Check: Is Steel Pipe Good for Earthquake Zones?

Steel pipes can be used in high-pressure systems with low risk of ground movement or soil liquefaction, like gas and oil pipelines, where flexibility is not the primary choice.

Ductile Iron Pipes (DIP): Corrosion Resistance and Strength

Ductile iron pipes or DI pipes, whose carbon content makes them more flexible than steel. These pipes are more likely to resist seismic events; however, this requires a restrained joint for seismic systems. Here are what DI pipes are used for in seismic zones:

- Weight: Ductile iron pipes are rigid to install because they are heavy, especially in soils that aren’t stable.

- Performance: These pipes work well in places with moderate seismic activity, but they aren’t the best choice for places with a lot of ground movement or extreme seismic activity. (S. Pipe)

Seismic Joint Systems

Advanced joint systems that allow for axial movement and stop joint separation are what make ductile iron pipes work well in seismic zones.

HDPE Pipes: Flexible and Light, But Deforms under Heavy Loads

High-Density Polyethylene (HDPE) pipes are known for their lightweight and flexibility in design. However, seismic pipes with fused joints include no leakage, but they may crack or deform under stress and high-pressure systems.

- Lower pressure ratings than materials that are rigid, like steel and ductile iron.

- Sensitivity to temperature, which can affect how well something works in very hot or very cold weather. (ScienceDirect)

- Long-term creep under constant loads, which could cause deformation over time.

Where are HDPE Pipes Used?

HDPE pipes with low risk of corrosion are the top choices for low- to medium-pressure systems like water distribution or gas pipelines in seismic areas. Then, choose them where flexibility is more important than strength.

PVC Pipes: Flexible but Deformation Included

Polyvinyl Chloride (PVC) pipes are such thermoplastics that include high terms of deformation under high-risk seismic events and vibrations. Also, these pipes are not that resistant to handling brittle fracture or joint disconnection, which makes them unpopular in seismic zones.

PVC pipes are very likely to break when they are under seismic stress, and they can also separate at the joints when the ground moves.

Where Should PVC Pipes Be Used?

PVC pipes are not a good choice for areas with a high risk of earthquakes or for important infrastructure where reliability is very important, because they are not very flexible.

Composite Pipes (GRP / GRE / GRV): The Best Option among All Pipelines

Composite pipes are the top choice for seismic zones and places where the risk of earthquakes may threaten the piping systems for crack and joint separations. These pipes include three main types:

- Glass Reinforced Plastic (GRP)

- Glass Reinforced Epoxy (GRE)

- Glass Reinforced Vinyl Ester (GRV)

Composite pipes are a design of glass fibers and a resin matrix that can last over 50 years or more if handled correctly. Their exceptional mechanical properties let them resist harsh vibrations with no changes included.

Where Exactly Do Composite Pipes Suit Seismic Zones?

High strain tolerance, lightweight, and fatigue resistance of composite pipes make them perfect for places where the risk of vibration and ground movements may ruin the whole system.

- High strain tolerance without breaking easily, which allows the ground to move a lot.

- Lightweight construction cuts down on inertial forces when the ground moves, which lowers the chance of pipes breaking.

- The pipe can handle a lot of stress without breaking, which helps it stay strong during repeated seismic events.

How Compatible Is The Design Of Composite Pipes In Seismic Zones?

Composite pipes can handle these scenarios due to their perfect coupling jointing systems for both axial movements (to expand or contract with the pipe’s length) and deflections (angular ones that flex and rotate pipes in seismic shifts). (Source: MDPI)

Core Applications

Composite pipes, as mentioned above, are the top choices for seismic zones and various use cases with their flexible specifications. Applications are:

- Water transmission

- District cooling

- Wastewater

- Industrial pipelines

Technical Insight: Composite pipes are engineered and designed to resist seismic conditions with their sturdiness under high-pressure systems, while their flexible design helps them show no deformation in ground movements or liquefaction of soils.

Seismic Performance Comparison: Composite Pipes vs Alternative Pipelines

Check the table below to compare all existing pipes for seismic zones to determine if your selected option is the best one.

|

Criteria |

Steel | Ductile Iron | HDPE | PVC | Composite (GRP/GRE) |

|---|---|---|---|---|---|

| Flexibility / Strain Capacity | Very Low (0.1-0.3%) | Low–Medium (0.5-1%) | Very High (10-20%) | Very Low (0.2-0.4%) | Medium–High (2-10%) |

| Joint Movement Tolerance | Low (1-2mm) | Medium (1-5mm, joint-dependent) | High (up to 10-20mm) | Low (1-3mm) | High (up to 25mm) |

| Resistance to Ground Displacement | Low | Medium | High | Very Low | High |

| Pressure Capability | Very High (up to 1000 bar) | High (up to 40-60 bar) | Medium (up to 16 bar) | Medium (up to 16 bar) | High (up to 60-100 bar) |

| Seismic Fatigue Resistance | Low | Medium | High | Low | High |

| Weight / Installation Ease | Heavy (25-30 kg/m) | Heavy (30-50 kg/m) | Very Light (5-10 kg/m) | Light (3-6 kg/m) | Light (4-12 kg/m) |

| Corrosion Resistance | Low | Medium | High | High | Very High |

| Suitability for Critical Seismic Infrastructure | Medium | Medium | Medium | Low | High |

| Temperature Sensitivity | Low | Medium | Medium | Low | Low |

| Long-Term Durability | Medium | Medium | Medium | Low | Very High |

| Installation Cost | High | High | Low | Low | Medium |

Why This Comparison Matters

Once you get to know each pipe and its mechanical and material specifications, it’s time to consider a variety of effective factors that aim to create a long-lasting piping system that requires the least maintenance. Here are what to consider when comparing these pipes:

Strength vs. Flexibility

Steel and ductile iron pipes, as metallic pipes, are strong and resistant to heavy loads and high-pressure systems. At the same time, they fail in cases with flexibility requirements.

HDPE and PVC pipes are flexible enough for seismic zones, but they deform and crack under external forces, and can work for medium-pressure lines with moderate gravel.

Engineered Flexibility of Composite Pipes

Composite pipes are designed in case of material and joints to withstand damaging earthquakes via their flexible jointing systems. Also, they’re the optimal case due to high fatigue resistance in vibrations.

Durability and Cost Efficiency

Composite pipes include a higher initial cost of material compared to other pipes, while they’re the best option in terms of final costs, including maintenance and repairs. Then, it’s obviously a composite pipe for places with a high risk of seismic damage.

Why Flexibility Is the Crucial Aspect in Seismic Pipelines

In seismic zones with extreme risk of vibration and ground movements, the flexibility of both material and design of pipelines helps them last without damage in these conditions. Unlike sturdy materials like steel or ductile iron, flexible pipes like composite pipes are more likely to be chosen as an earthquake-resistant option.

Comparison of Elastic Modulus Across Materials

The elastic modulus of each pipe material shows how they will behave under pressure and probable movement without breakage or cracking. Check the table below, which represents the elasticity modulus ranks.

| Material | Elastic Modulus | Axial Displacement | Angular Deflection |

|---|---|---|---|

| Steel | High | Limited | Very limited |

| Ductile Iron | Medium | Limited | Moderate |

| HDPE | Low | High | High |

| PVC | Low | Very limited | Very limited |

| Composite (GRP/GRE) | Medium–Low | High | High |

Why Controlled Flexibility Outperforms Rigid Strength

While rigid strength includes the primary resistance to pressure and movements, it won’t be enough for long-term performance. Then, it comes to controlled flexibility for pipes to handle these constant and continuous seismic events over time.

Composite Pipes in Pipeline Systems that Can Handle Earthquakes

As we discussed in the last sections, composite pipes are the best and most reliable option for seismic zones where earthquakes may fail the whole piping system, whether in water infrastructures or industrial uses. Now. Let’s dive deeper into this pipe composition and their design:

Material Composition of GRP, GRV, GRE Pipes

Composite pipes are made of fiberglass reinforcement and a resin system, which gives them a strong and flexible construction.

Mechanical Properties

To satisfy specific seismic needs, these pipes can be made stronger or more flexible, which makes them operate better.

Inspection: Non-Metallic Pipe under Seismic Forces

Composite materials are less likely to break or crack than metal pipes because they are more flexible and can handle seismic loads better.

Composite Pipes’ Function in Seismic Performance

Composite pipes are great for places that are likely to have earthquakes because they can tolerate a lot of ground movement without breaking.

Lightweight of Composite Pipes

Because they are not very heavy, they are less likely to be affected by earthquakes, which makes pipelines more stable.

These pipes are useful when there are cyclic seismic loads, and they don’t wear out very rapidly.

Composite Function under Deep Burials: Scribd notes that even when the ground shakes during earthquakes, composite pipes operate exceptionally well in buried pipeline systems.

The Role of Joints in Seismic-Resistant Composite Pipelines

The most commonly heard problem with seismic zones in pipelines is not only the cracks, but also the way they connect together. The chosen jointing method should be aligned with the conditions of that site and earthquake requirements. Points below aid you in choosing the best method among the strained and restrained ones.

- Composite pipes with flexible couplings that can handle earthquakes allow the pipeline to move with the ground, which puts less strain on the joints.

- These joints let the pipeline move along its axis and bend at an angle, which means it can handle changes in the ground without breaking.

- Composite joints maintain working without leaking even when they are moved a lot, yet rigid systems may break when they are under stress.

- Flexible joints are superior to welded and rigid systems because they are more flexible and stay robust when the ground shakes.

Typical Applications of Composite Seismic Pipelines

Composite pipes are used in many applications due to their perfect performance under extreme conditions. Also, their flexible yet strong walls allow them to be set in seismic zones with no changes or cracks.

- Water Transmission Lines: Composite pipes are used in water infrastructure, like water distribution, due to their changeable design in various lengths and wall thickness, especially in earthquake zones, when joints can also cause some scandals too.

- Wastewater and Sewer Systems: These pipes are a reliable solution for sewage systems, making sure that there is as little disruption as possible during earthquakes.

- District Cooling Networks: Composite pipes are great for district cooling because they don’t expand when they get hot or when they are shaken.

- Industrial and Utility Pipelines: These are used in industries that need strong and flexible pipelines for gas, chemicals, or other utilities in areas that are prone to earthquakes.

- Pipelines in Unstable Soils: Composite pipes are effective in areas with liquefaction of soils or fault lines, where the flexibility of pipes can handle ground displacement.

Why EPC Contractors Choose Composite Pipes for Seismic Projects

EPC contractors are looking for a pipeline that can withstand seismic events. These conditions require fast installations, reliable jointing, and walls with enough thickness to handle vibrations and ground shaking. Make sure the selected pipe includes the factors below:

- Flexible joints

- Structural integrity

- Long-term performance

- Corrosion resistance

- Low lifecycle cost

- low maintenance requirement

These factors provide contractors with reliable composite piping systems that last over 50 years.

Our Earthquake-Resistant Composite Pipe Solution

LineCore Pipes Group provides an engineered composite piping system for specific use cases. Some of the key benefits are that they have the right amount of flexibility and rigidity, can withstand earthquakes, and last a long time with little maintenance. Great for projects that are really important and in areas that are very likely to have earthquakes.

Get a quote from our expert consultant on our website PipeLineCoreGroup.com today!

FAQs

1- What makes composite pipes ideal for seismic zones?

Composite pipes themselves are the top choices for various use cases, from urban water transmission to large-scale industrial piping cases. In seismic zones with a high risk of vibration, composite pipes like GRP pipes can handle these troubles and transport fluids.

2- How do composite pipes compare to steel pipes in seismic performance?

Steel pipes are sturdy and strong under high-pressure flows and loads, while this matter is not crucial in seismic zones. What matters in this case relies on how pipes behave in vibration, liquefaction, and ground movements, where steel pipes mainly fail and composite pipes last with minimal risk of failure or cracks.

3- Are composite pipes maintenance-free?

Composite pipes require minimal maintenance due to their corrosion resistance and long-lasting performance, reducing overall lifecycle costs.

4- How long do composite pipes last in seismic regions?

Composite pipes are designed in a way (in the case of material and pipe design) to resist a harsh environment with less maintenance requirements than alternatives. They last over 50 years in certain conditions.

about

The Author

Farshid Tavakoli is a seasoned professional in engineering and international trade. Holding degrees in Electrical Engineering, Mechatronics, and a Doctorate in Business Administration (DBA) from the University of Lyon, he also has a strong background in industrial automation and production line technologies.

For over 17 years, he has led an international trading company, gaining deep expertise in commercial solutions tailored to industrial needs. With more than 8 years of active involvement in infrastructure development, he specializes in the supply of electromechanical equipment for water and wastewater treatment plants and transfer projects.

Together with comapny expert team, he now provides consultancy and integrated solutions for sourcing and implementing complex infrastructure projects across the region.