Offshore pipes have changed since the metallic era, which included tons of corroded pipes; engineers and contractors were looking for modern materials that resist marine conditions, as offshore applications require durable, corrosion-free, lightweight pipes like GRE (Glass Reinforced Epoxy) or GRP (Glass Reinforced Plastic).

It’s time to replace old infrastructures with composite pipes that last for decades in your project with no damage included. Stay sharp till the blog post’s end!

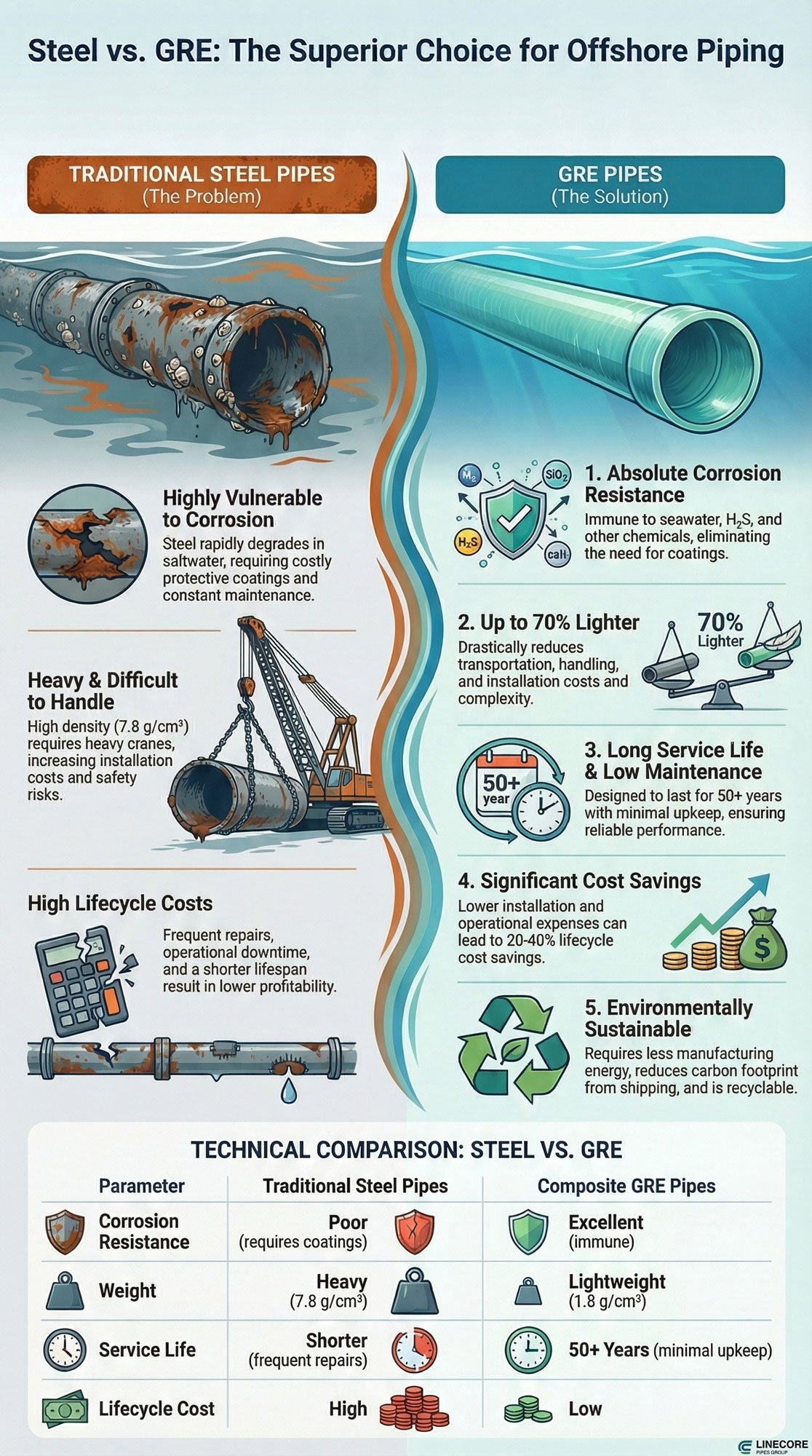

Before getting into the main post, check the table below to understand the metal pipes’ dilemmas and the superiority of composite pipes over metallic alternatives at a glance.

| Challenge/Aspect | Traditional Metal Pipes (e.g., Steel) | Composite Pipes (e.g., GRE/GRP) |

|---|---|---|

| Corrosion Resistance | Poor; needs coatings/CP, prone to failures in seawater/H₂S | Excellent; immune, no protection required |

| Weight and Handling | Heavy (7.8 g/cm³); requires big cranes, high logistics costs | Lightweight (1.8-2.0 g/cm³); 70% lighter, easier install |

| Installation Complexity | High; welding/heavy lifting, safety risks and delays | Low; modular joints, faster deployment, less welding |

| Maintenance & Service Life | Frequent repairs; shorter life due to wear | Minimal; 20-50 years with low upkeep |

| Lifecycle Cost | High; ongoing OPEX and downtime | Low; 20-40% savings over time |

| Environmental Impact | Higher; energy-heavy production, potential leaks | Lower; efficient, recyclable, reduced emissions |

What Are Offshore Pipes and Why Do They Matter?

To start the discussion of offshore, lets figure out what exactly they are and what pipes are referred to as offshore pipes.

A Closer Inspection: What Exactly Is An Offshore Pipe?

Offshore pipes are essentially used to join and make connections in offshore production lines and onshore facilities and systems. These operations need to run smoothly in energy sectors with effective piping choices.

Offshore Pipe Categories

Offshore pipes mainly contain four categories, each requiring specific characteristics that can be changed in design or material selection steps.

- Flowlines: Designed to run the oil and gas transportation from the production area to processing platforms.

- Risers: Eases the transmission of fluids from subsea to the platforms.

- Injection Lines: Carry water or gas to maintain pressure in reservoirs.

- Utility Piping: Adds the utilities such as water, air, or steam for the operation of main platforms.

Why Did Metallic Pipes Fail in Marine Condition?

Metallic pipes such as steel pipes are highly vulnerable to corrosion and the harsh and salty environment of seawater was the right place to make them corrode over time.

Chemical damages were another issue like acidic water, also biological corrosion coming from microorganisms in the oceans make it worse. (Source: MDPI)

These happenings resulted in costly maintenance and repairs in marine conditions that primary installation was hard itself.

Further installation and jackings require heavy equipment due to the heaviness of steel pipes which increases the cost of maintenance and logistics at the same time.

What’s the Solution? Composite Pipes Such as GRP and GRE Pipes

Composite pipes are lightweight, resistant to many scandals like high temperature, pressure, and corrosive systems, and require lesser maintenance compared to the steel pipes with high risk of physical damages and extra expensive protective coatings.

| Feature | Composite Pipes (GRE/GRP) | Steel Pipes |

|---|---|---|

| Corrosion Resistance | Corrosion-free, no coatings needed | Prone to corrosion in seawater |

| Weight | Up to 70% lighter, easier handling | Heavy, requires heavy cranes |

| Maintenance | Low maintenance, longer lifespan | High maintenance, frequent repairs |

| Durability | High resistance to mechanical damage | Susceptible to impact damage |

| Installation | Easy to install, fewer inspections | Complex, requires welding |

| Cost Efficiency | Lower lifecycle and operational costs | Higher long-term costs |

Challenges of Traditional Offshore Pipeline Systems

Traditional steel pipelines used in offshore platforms faced many troubles during their lifetime. This makes them controversially notorious in offshore platforms. At the same time, this limitation doesn’t exist in composite pipes. Let’s check them all.

Corrosion in Seawater and Chemical Systems

Steel pipes are highly susceptible to salty and corrosive saltwater chemical environments. This means they require protective coatings that must be maintained from time to time.

Also, regular inspections are intensively adding to costs and the offshore team’s effort to keep pipes working during their short lifetime. Eventually:

- Corrosion: Steel breaks down in salt water.

- Repairs: Needs regular maintenance.

- Coatings: Layers of protection that cost a lot.

- Downtime: Maintenance slows down productivity.

That’s why steel pipes are no longer the top choice of offshore platforms.

Weight and Handling Issues with Steel Installations

Steel pipes are much heavier than composite pipes and more difficult to install in hard-to-access sites like offshore pipes deep in the oceans. This heaviness requires heavy cranes to handle them to the final destinations. In short:

- Steel needs special tools for moving it.

- Bigger cranes are needed for installation.

- More people are needed to get them to the place.

Extra Coating, Welding, and Inspection Requirements

While the installation process of steel pipes requires heavy cranes, professional workers, and periodic inspections, this also adds an extra cost of coatings on the joint section and welding, which all make the process more complicated and cost-intensive.

- Steel needs protective coatings often.

- It takes a long time to install and fix things.

- To keep things safe, they need to be checked often.

Timely Repair and Downtime: High Lifecycle Costs

Once steel pipes are installed, they require constant inspection for any evidence of corrosion that causes cracks and leakage. These problems can ruin the whole system while decreasing the beneficial lifecycle of steel pipes.

- Shorter Lifespan: Needs to be replaced often.

- Costs: Repairs that need to be done all the time add to costs.

- ROI: High costs make it less profitable.

That’s why the ROI rate of steel pipes is more considerable than that of composite pipes.

Composite Offshore Pipes (GRE, GRP, and RTR): An Introduction

Composite offshore pipes are such resistant pipes under offshore settings due to their perfect characteristics, like corrosion resistance and good tolerance under high-pressure loads and flows (Source: ScienceDirect). These pipes are made of glass fibers and a resin matrix that enables them to resist harsh marine conditions. Including:

- Glass Reinforced Epoxy (GRE)

- Glass Reinforced Polyester (GRP)

- Reinforced Thermoplastic Resin (RTR) pipes

GRE pipes with epoxy resin are the best option for offshore platforms that provide resistance against high temperatures, pressures, and corrosive materials.

Manufacturing Process: How GRE Pipes Are Made

GRE pipes can be manufactured from several methods, such as filament winding, centrifugal casting, or hand lay-up. Glass fibers are impregnated with resin and wrapped around a rotating mandrel to get the pipe shape. Then, the resin must be cured to harden.

Composite pipes like GRE pipes include three main layers: the inner layer, the structural layer, and the outer layer.

- In the internal layer, as noted in Scribd, centrifugal casting makes a smooth inner surface to reduce the pumping energy requirements.

- Structural layer with glass fibers that represents good strength and durability under heavy loads.

- Outer layer covered with resin and additives, prepared to fight harsh and UV light probable damages.

Key Properties of Composite Offshore Pipes

Corrosion Resistance: GRE pipes don’t corrode when they come into contact with seawater, chemicals, or other corrosive materials, so there is no need for coatings or cathodic protection that increase the cost of maintenance and materials.

Low Density: GRE pipes are much lighter than steel (like 1/4 or 1/5), which lowers installation costs and the need for heavy equipment like cranes.

Chemical Resistance: These pipes can withstand a wide range of chemicals, including acids and alkalis, so they can be used for complicated offshore operations.

Temperature and Pressure Ratings

Check the table below for specifications of GRE pipes, including their DN, PN, and SN ratings.

| Rating | Typical Values for GRE Pipes |

|---|---|

| DN | 25mm to 1200mm |

| PN | 6, 10, 16, 25 bar |

| SN | 2500, 5000, 10000 N/m |

Also, GRE pipes with epoxy resin type used in their materials and special additives can resist up to 120 °C and even up to a thousand degrees for a limited time in oil and gas pipelines. (FuturePipe)

How GRE Pipes Are Aligned with Offshore Fluids

GRE pipes with their magnificent properties are such top-notch choices for offshore plants (seawater, chemicals, and produced water).

This ability to resist aggressive conditions with the least maintenance requirement keeps them away from replacement or any probable failures.

5 Reasons Why GRE Composite Pipes Are The Best Option for Offshore Applications

GRE composite pipes are one of those modern solutions for offshore plants. They solve those problems with old infrastructure, such as steel pipes made before, like corrosion, weight, or maintenance. Here are five bright situations where GRE pipes shine:

1. Absolute Corrosion Resistance

GRE pipes are popularly used in offshore systems due to their thought-provoking layer of resin, which makes them resistant to corrosion, showing no degradation over time in harsh environments:

- Seawater

- Hydrogen sulfide (H₂S)

- acids

- Chlorides

This property keeps GRE pipes away from expensive maintenance and repairs in hard-to-access lines.

2. Lightweight and Easy to Handle

GRE pipes, due to their glass fiber material, are really heavier than alternatives like steel or concrete pipes. This benefit (lighter weight than steel up to 70%) makes the transportation, handling, and installation easier than steel pipes. (Source: ResearchGate)

- No need for heavy cranes.

- Less time is needed for the installation process.

Also, with various jointing methods, GRE pipes can be designed in many lengths that reduce the need for expensive transportation.

3. Long Service Life and Low Maintenance

GRE pipes are designed to last for decades with fewer requirements for maintenance in harsh and aggressive marine settings. The lifespan of GRE pipes goes up to 50 years or more in certain conditions.

- Minimal Upkeep: Requires less maintenance over time.

- Predictable Performance: Reliable in harsh conditions.

- Reduced Costs: Fewer repairs and downtime.

This extended service life of GRE pipes is what old steel pipes failed for years, and get corroded, resulting in costly repairs.

4. Cost Efficiency Over Project Lifecycle

GRE pipes include such savings on costs. Unlike their expensive initial cost of material and manufacturing process, they are more cost-effective than steel pipes in terms of overall cost.

- Fewer installation requirements, though it’s expensive.

- Higher productivity and less downtime.

- Less need for repair when the rate of degradation is near zero.

Compared to CRA and coated steel pipes, where these layers add to the material cost itself, periodic inspections are another issue that GRE pipes refuse to address.

5. Environmentally Sustainable: Following the Green Trends

Despite the plastic nature of GRE pipes, they can handle chemicals and stress better than their alternatives, which reduces the need for repairs. Also, they require fewer heavy cranes for handling, which can both save money and reduce pollution.

- Lower manufacturing energy consumption.

- GRE pipes are recyclable and produce less waste.

- Requires less shipping and lowers the carbon footprint.

What Are Typical Offshore Applications for GRE Pipes?

GRE pipes are popularly used in offshore applications due to their superiorities compared to steel pipes and even other types of FRP pipes. They are corrosion-resistant, lightweight, and strong under high loads and pressures.

● Seawater Cooling

In topside seawater cooling and firewater networks, where resistance to corrosion of seawater (microorganisms included) and chemicals makes GRE pipes the top choice for transportation of fluids in these systems.

● Ballast and Bilge Systems

In vessels, to control the water intake and discharges, a resistant pipe like GRE pipe can be used in the system that avoids the risk of flooding in long-term performance.

● Chemical Lines

The case of produced water and chemical injection systems requires pipes that can handle harsh chemicals in the oil and gas extraction process with no risk of fire or deformation during the transportation of fluids.

● Desalination Systems

In the utility pipelines, GRE pipes are used for several steps of line transmission of water, steam, or other materials. Corrosion-free and durable GRE pipes are the best option there.

● Subsea Lines

In the outfalls and intakes, GRE pipes are used for wastewater and seawater in multiple choices. The lighter weight compared to alternatives makes GRE pipes easier to handle and manage.

● Floating Structures

Society of Petroleum Engineers defines cases like FPSOs, FSOs, and platforms, which require dynamic marine states to use GRE pipes with lightweight and corrosion resistance to transform fluids with no leakage or changes in the flow rating.

GRE vs Steel in Offshore Environments: A Technical Comparison

As we discussed in the last sections, GRE pipes are superior to steel pipes due to their magnificent characteristics. Now, check both pipelines to make sure which pipe is the best for your project.

| Parameter | GRE Pipes | GRP Pipes | Carbon Steel | Duplex/CRA Pipe |

|---|---|---|---|---|

| Corrosion Resistance | Excellent; immune to seawater/chemicals (H₂S, CO₂, chlorides) | Good; resists acids/alkalis | Poor; needs coatings/CP | Good; pitting-resistant in chlorides/sour gas |

| Weight | Low (1.8-2.0 g/cm³, 70% lighter) | Low (1.8-2.0 g/cm³) | High (7.8 g/cm³) | High (7.8 g/cm³, thinner walls possible) |

| Installation | Easy; adhesive joints, no welding | Easy; flanged/adhesive, prefab | Complex; welding, heavy equip | Moderate; weldable, pre-fab |

| Maintenance | Minimal; 50+ years | Low; 20-40 years | High; frequent repairs | Low-moderate; 30-50 years |

| Lifecycle Cost | Low; 40% OPEX savings | Low; 20-30% savings | High; high downtime | Moderate; long-term savings |

| Pressure Rating (PN) | Up to PN32 (1-32 bar) | Up to PN40 (1-40 bar) | Sch40-160 equiv (up to 500 bar) | High (up to 500 bar) |

| Nominal Diameter (DN) | DN100-4000 mm | DN200-4000 mm | DN15-2000 mm | DN15-800 mm |

| Stiffness Class (SN) | SN2500-20000 N/m² | SN2500-10000 N/m² | N/A | N/A |

| Temperature Range | Up to 120°C | Up to 80°C | -29 to 425°C | -50 to 300°C |

| Standards Compliance | ISO 14692, API 15HR | AWWA C950, BS 7159 | ASME B36.10M, API 5L | API 5LC, ASTM A790 |

| Ideal Use Cases | Offshore utilities in corrosives | General offshore water | High-pressure flowlines | Sour/subsea corrosives |

GRE Offshore Pipe Installation and Jointing

GRE pipes can be connected and installed in various ways that make them perfect for many applications, while they allow them to be designed in many lengths. Here are some jointing methods in short:

- Flanged Joints: Use bolts and gaskets to make sure connections are strong. These are great for topside systems.

- Adhesive-Bonded (Bell & Spigot): Strong, permanent joints created with epoxy that can handle high pressure. (Scribd)

- Mechanical Couplings: These are quick, flexible couplings that use seals and O-rings. They work well in offshore settings.

- Double O-Ring Bell & Spigot: With two O-rings, this product seals well and is great for installations that are underwater or buried.

- Laminated (Butt & Wrap): Strong joints for big diameters that need to be installed by someone with experience.

- Key-Lock or Restrained Couplings: These stop axial force, which keeps things stable under pressure.

The Flexibility Of Design for Joints and Fittings

GRE pipes are made to be spooled and modular, which is a big plus for offshore installations.

- Pre-Fabricated Modules: GRE pipes are made in advance, which makes them easier to move and faster to put together on site.

- Quick Installation: Modular design makes it possible to install things more quickly offshore.

- Lower Expenses: Faster installation lowers the costs and timeframes of the whole project.

Works with S-lay or Modular Topside Prefabrication

GRE pipes work very well with S-lay technologies and modular topside prefabrication, which makes offshore installation as good as it can be. GRE pipes are compatible with the S-lay installation method, which makes things easier.

Also, GRE pipes work well with modular prefabrication, making logistics and installation easier.

Less time and risk of injury when welding offshore

Mechanical and adhesive couplings in GRE pipes cut down on the necessity for welding on the water.

- Mechanical and adhesive couplings make welding unnecessary, which can take a long time and be dangerous.

- The installation process goes faster because there is less time spent welding.

- Reducing the amount of welding lowers the dangers to workers’ safety when they are operating offshore.

Each option helps make the process of installing offshore pipelines faster, safer, and less expensive.

Standards and Guidelines for GRE Offshore Pipes

GRE pipes follow international guides and standards for engineers to make sure of the final result and their alignment for all sites and climates. Check the table below for the most-used standards of GRE pipes:

| Standard | Scope | Application |

|---|---|---|

| ISO 14692 | Offshore composite pipe systems | Design, materials, installation |

| ASTM D2996 | Filament-wound fiberglass pipes | High-pressure composite pipes |

| API 15LR/15HR | Fiberglass reinforced pipes | Pressure ratings, installation, testing |

| DNV-ST-F101 | Offshore pipeline design and construction | Offshore system integration |

Quality Control and Hydrostatic Testing Procedures

Once the pipes are installed, it’s time to test them via various methods, like hydrostatic testing, which checks the whole pipeline for any probable leakage in its lifetime based on ASME B31.

Major Operators and Class Societies Certify

Major operators and class societies have verified GRE pipes, which means they meet global standards. These certifications mean that the pipes follow the best procedures in the industry and are safe to use in offshore and subsea projects.

Your Trusted Partner to Choose GRE Offshore Pipelines

LineCore Pipes Group is your partner for GRE pipes in the offshore project, not only in designs and choice of material, but also in installation for both topside and subsea applications. Our expert team helps you to choose the best choice for stress, pressure, and flow analysis from design to installation and further tests.

Keep in touch with our consultant for reliable spans in the oil and gas, marine, and renewable projects. Contact info@PipeLineCoreGroup.com today and get a quote!

FAQs

1- What are GRE pipes?

GRE pipes made of glass-reinforced epoxy resin, which are known for their corrosion resistance and lightweight properties.

2- What are the benefits of GRE pipes?

GRE pipes include corrosion resistance, lightweight, low maintenance, and cost efficiency for offshore applications.

3- Are GRE pipes suitable for subsea installations?

Yes, GRE pipes are perfect for subsea applications due to their resistance to seawater corrosion and chemical degradations.

about

The Author

Farshid Tavakoli is a seasoned professional in engineering and international trade. Holding degrees in Electrical Engineering, Mechatronics, and a Doctorate in Business Administration (DBA) from the University of Lyon, he also has a strong background in industrial automation and production line technologies.

For over 17 years, he has led an international trading company, gaining deep expertise in commercial solutions tailored to industrial needs. With more than 8 years of active involvement in infrastructure development, he specializes in the supply of electromechanical equipment for water and wastewater treatment plants and transfer projects.

Together with comapny expert team, he now provides consultancy and integrated solutions for sourcing and implementing complex infrastructure projects across the region.