By passing the metal pipes era, it’s time to bring in more durable and resistant pipes to the game. Non-metallic pipes, such as plastics and composites, with their lightweight and corrosion resistance, solved problems rooted in metal nature, such as heavy weight in transportation and the need for repair in corrosive conditions.

These pipes come in three central categories: thermoplastics, thermosets, and composites, which are fully explained in this post. Stay tuned till the end.

To achieve a base perspective of this matter, check the table below showing how non-metallic pipes differ.

| Pipe Type | Material | Properties | Applications |

|---|---|---|---|

| Thermoplastic Pipes | |||

| PVC / CPVC | PVC / Chlorinated PVC | Corrosion-resistant, moderate temp tolerance | Water, drainage, chemicals |

| HDPE / LDPE | Polyethylene | Flexible, chemical-resistant | Water, gas mains, irrigation |

| PEX | Cross-Linked Polyethylene | Flexible, heat-resistant | Plumbing, heating systems |

| PP / PPR | Polypropylene | Chemical and heat-resistant | Water systems |

| ABS | Acrylonitrile Butadiene Styrene | Impact-resistant, temperature-resistant | Drainage, stormwater |

| UPVC | Unplasticized PVC | Rigid, durable | Water/sewer piping |

| Thermosetting & Rubber-Based Pipes | |||

| Rubber Pipes | Synthetic rubber | Flexible, vibration-dampening, heat-resistant | Marine, chemicals |

| Concrete/Clay Pipes | Concrete / Clay | High load-bearing | Sewer, stormwater |

| Composite & Reinforced Pipes | |||

| Aluminum-Plastic / Steel-Plastic | Composite | Lightweight, corrosion-resistant | Fluid transport |

| FRP / GRP / GRE / GRV Pipes | Fiberglass, Epoxy, Vinyl ester | High-strength, corrosion-resistant | Water, oil & gas, offshore |

| RTP | Thermoplastic + fiber | Flexible, high-pressure-rated | Oil & gas, fluid transport |

Non-Metallic Pipe Types: From Thermoplastics to Composites

Non-metallic pipes are the top choice in both industrial and general applications due to their beneficial characteristics. There are three core categories, each divided into different pipelines: thermoplastics, thermosets & rubber-based materials, and composite & reinforced pipes.

1. Thermoplastic Pipes

Thermoplastic pipes include such useful properties as recyclability, resistance to corrosion, and high temperature, while being lightweight to ease the handling and transportation process.

Types of Thermoplastic Pipes:

PVC/CPVC: These pipes are used in general use cases such as water supply, drainage, and chemical plants. CPVC shows better resistance to high temperatures compared to PVC.

HDPE/LDPE: HDPE pipes are strong yet flexible, standing against chemicals and UV light in potable water and gas mains. LDPE pipes are more flexible and are used for low to medium-pressure pipelines.

PEX: Flexible and resistant to temperature changes, and used for plumbing systems and radiant heating.

PP/PPR: PP pipes can withstand heat and chemicals like acids, making them perfect for industrial use cases. PPR pipes, as a type of polypropylene, are used for urban water systems due to their tolerance of high pressures.

ABS: ABS pipes mainly work for drainage systems where a cold climate requires resistance to low temperatures.

UPVC: UPVC pipes can be helpful where long-term performance and well-structured pipes are needed, like in sewer systems.

2. Thermosetting & Rubber-Based Pipes

These pipes are made for more specific use cases where high temperature and chemicals require pipes with better heat resistance or vibration-dampening.

Rubber Pipes: They can reduce the risk of vibration damage in chemical processing, while being durable and flexible in pipeline design.

Concrete/Clay Pipes: Though they can’t be considered as non-metallic pipes, they are used in old infrastructures where heavy external loads can cause deformations.

3. Composite & Reinforced Non-Metallic Pipes

These pipes are a combination of flexible plastics and resistant glass fibers. The layered design of these pipes and the chance of adding protective layers make them the best option among non-metallic pipes for various use cases.

Aluminum-Plastic/Steel-Plastic Composite Pipes: They are lightweight yet strong for fluid transmission.

FRP/GRP/GRE/GRV Pipes: These pipes are made of fiberglass and resin, making them lightweight and resistant to corrosion, pressure, and temperature in various applications.

RTP Pipes: These pipes are a combination of thermoplastic and reinforced fibers that include features of both and are used in high-temperature and pressure pipelines.

A Deeper Dive into Composite Pipes and FRP Family: GRP, GRV, GRE

Composite pipes are made of complex materials such as fiber, resin matrix, and additives, making them such top choices in harsh and aggressive environments, which can last over decades with the least need for maintenance.

What Are the Main Types of Composite Pipes?

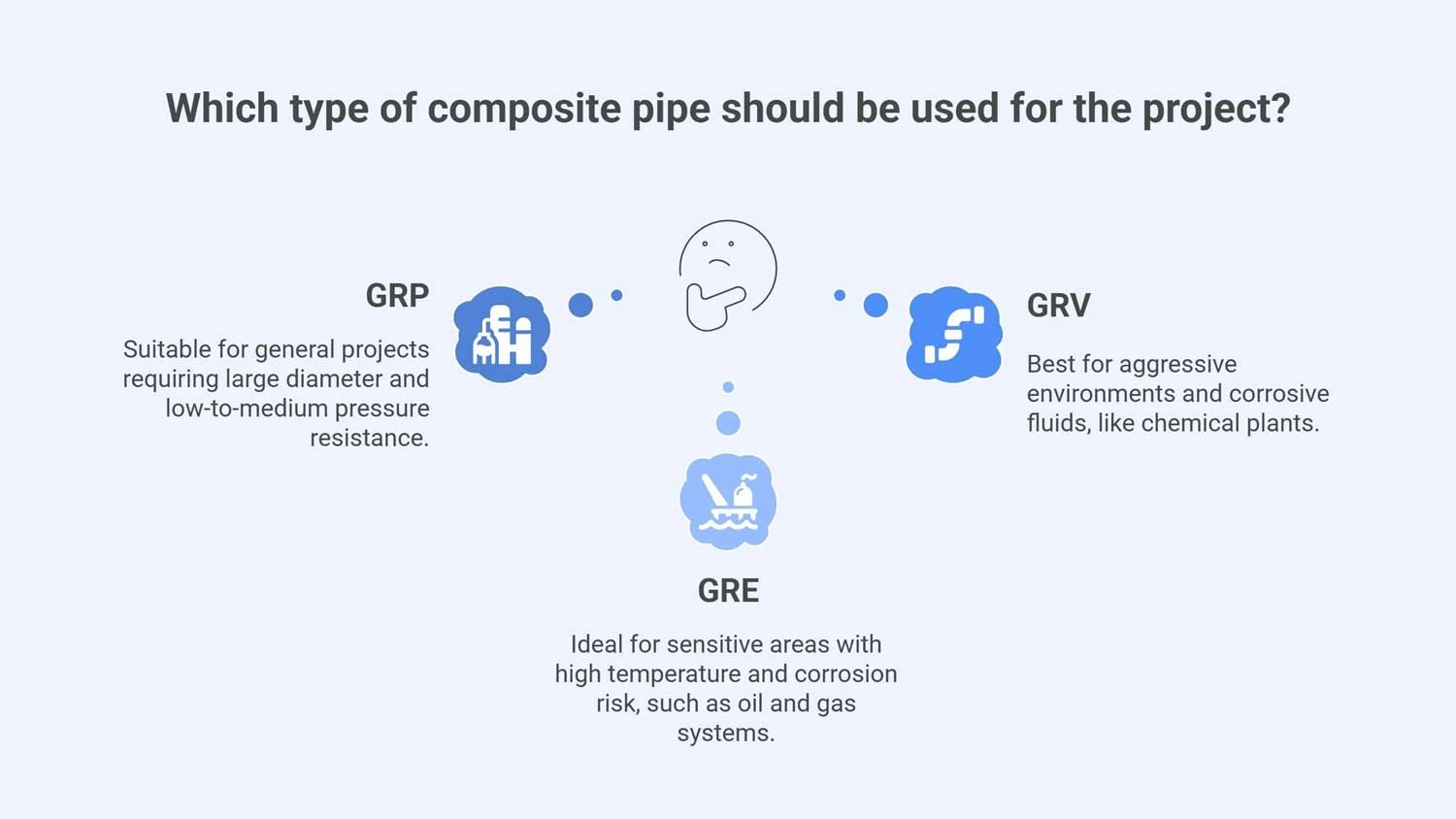

There are three central pipes, GRP, GRV, and GRE pipes that are famously used across industries to ease the transportation and installation process.

1. GRP (Glass Reinforced Plastic)

GRP pipes are made of glass fibers and polyester resin matrix via continuous filament winding. These pipes resist under high pressure and heavy loads due to the layered structure, while the smooth inner surface lowers the need for pumping energy. They include such use cases:

- Water and wastewater pipelines

- Irrigation and desalination system

- Cooling and utility networks

Choose GRP pipe for general projects where the system needs a large diameter and low-to-medium pressure resistance.

2. GRE (Glass Reinforced Epoxy)

GRE pipes are made of glass fibers like GRP pipe, but the epoxy resin changed the game, adding a higher resistance to temperature for more risky sites like oil and gas systems. This superior temperature and pressure resistance, combined with fatigue performance and non-conductivity, in applications such as:

- Oil and gas production and processing

- Marine and offshore piping systems

- Firewater and hydrocarbon transmission

Choose GRE when looking for long-term performance in sensitive areas with a high risk of corrosion with no protective coating layer needed.

3. GRV (Glass Reinforced Vinyl ester)

GRV pipes are made of the same material as previous pipes. However, ScienceDirect highlights that the vinyl ester resin in this pipe makes it stronger than others against chemicals and solvents. They transport acids and alkalis with no degradation or need for repair. The long lifespan and corrosion-free features of GRV contain such use cases:

- Chemical and petrochemical plants

- Desalination and wastewater treatment systems

- Industrial transmission lines

Choose GRV when aggressive environments and corrosive fluids are the weak spots of your project, in which GRV selection can solve them.

Manufacturing Process of GRP, GRE, and GRV Pipes

Composite pipes are manufactured by various methods, with filament winding being the most commonly used one.

- This process starts with the preparation of the materials, such as soaking the glass fibers in resin, and then the glass fibers go through winding around a mandrel to get shaped.

- The fiber orientation (hoop, axial, or helical) indicates how strong the pipe can be under heavy loads.

- After all, they must be cured by heat to harden. Standards such as IS 12709 help manufacturers align pipes with global demands.

Mechanical Properties of Composite Pipes

The mechanical strength of these pipes depends on the orientation and layering; for instance, high hoop and axial strength in GRE pipes prevents them from deforming under high pressures.

- Orthotropic vs Isotropic: Unlike isotropic metal pipes that act the same in all directions, composite pipes can resist both internal and external pressure by their orthotropic

Furthermore, the non-conductive nature, high-pressure rates, and thermal tolerance of composite pipes enable them to surpass metal pipes in both under- and above-ground pipelines.

Application of each GRP, GRV, and GRE Pipes

As we mentioned in the last section, let’s take a quick look at their applications to double-check your selected pipeline and project requirements.

| Application | GRP | GRE | GRV |

|---|---|---|---|

| Desalination and Water Treatment Plants | Yes | Yes | Yes |

| Oil & Gas Transmission and Processing | No | Yes | No |

| Chemical Factories | Yes | Yes | Yes |

| Wastewater Facilities | Yes | Yes | Yes |

| Fire Water Systems | Yes | Yes | No |

| Infrastructure (Cooling Water, Sewer) | Yes | No | Yes |

| Offshore Applications | Yes | Yes | Yes |

Design Considerations of Composite Pipes

Once pipes are produced, there are still several standards and aspects that must be considered for a reliable piping system:

A. Standards

ISO 14692 is one of those standards used for design, testing, and installation of composite pipe around the world that aligns project requirements with industry policies and conditions.

B. Joint Type and Support Spacing

The proper jointing method selection can prevent early maintenance in pipelines, which we insist requires less maintenance than metal pipes. Consider pipe sizes and application to avoid probable damage.

C. Corrosion and Erosion Resistance

Composite pipes can resist corrosive conditions due to the resin material. This resin type avoids chemical and UV exposure for long-term performance in harsh environments.

D. Pipe Thickness

Pipes are designed to tolerate certain pressure, though they can be customized to project demand by increasing the wall thickness in deeper buried pipelines.

Comparison Table of Composite Pipes: The Case of GRP, GRE, GRV Pipes

This section compares these three pipes via their specific applications, properties, and features to help you choose the most relatable pipeline for your industrial needs.

| Property | GRP (Glass Reinforced Plastic) | GRE (Glass Reinforced Epoxy) | GRV (Glass Reinforced Vinylester) |

|---|---|---|---|

| Resin | Polyester or Vinyl ester | Epoxy | Vinyl ester |

| Key Strengths | Corrosion resistance, cost-effective | High strength, fatigue resistance | Chemical resistance, ideal for aggressive media |

| Pressure Rating | 16-25 bar | Up to 40 bar | 20-25 bar |

| Temperature Tolerance | 50°C to 90°C | Up to 120°C | 60°C to 90°C |

| Chemical Resistance | Good for water, acids, seawater | Strong against hydrocarbons, chemicals | Exceptional for acids, solvents, oxidizing agents |

| Flexibility | Moderate | Low | Moderate |

| Durability | 50+ years | Very high service life | Long service life in aggressive media |

| Applications | Water supply, wastewater, cooling networks | Oil & gas, offshore, firewater, hydrocarbon transport | Chemical plants, wastewater, acid lines |

| Impact Resistance | Moderate | High | High |

| Installation | Easy, lightweight | Requires careful handling | Moderate ease of installation |

| Cost | More cost-effective | Higher due to epoxy resin | Higher due to superior properties |

What Are the Advantages of GRP / GRE/ GRV Pipes?

GRP, GRV, and GRE pipes provide several benefits for both industrial and urban piping systems:

- Corrosion Resistance: These pipes resist corrosion due to the protective layers of resin that can reduce the need for expensive and timely maintenance.

- Long Lifespan: These pipes can last over 50 years if installed correctly, which, in comparison with metal pipes, includes a lower overall cost.

- Lightweight: One point that makes these pipes superior to metal pipes is the higher strength-to-weight ratio that can be handled and installed easily.

- Resistance to chemicals and aggressive matters: GRP, GRE, and specially GRV pipes can handle different acids, alkalis, and solvents with no degradation in industrial use cases.

- Customized Design: These pipes can be designed based on the project demands in various pressures, sizes, and lengths.

- Other Advantages: Their non-conductive nature and thermal tolerance in sensitive applications like oil and gas pipelines make them a top choice.

Why Choose Composite Pipes Over Metallic Ones?

Composite pipes surpass metal pipes due to several advantages they offer in various industrial applications:

No Internal/External Corrosion: Unlike metals, composite pipes are resistant to corrosion with no need for extra protective coating and linings.

No Cathodic Protection or Chemical Inhibitors: Composite pipes don’t need additional chemical resistance layers or cathodic protection systems, which reduces both the cost for maintenance and extra layers.

Faster Installation, Lower Labor Costs: According to Scribd, their lightweight nature and high strength-to-weight ratio make them easy to handle, which can reduce the need for professional workers and labor.

Lower Lifecycle Cost & Better ROI: Due to their durability, corrosion resistance, and low maintenance needs, composite pipes often offer a lower total cost of ownership and provide a better return on investment over their lifespan.

- 50+ years lifespan

- No corrosion

- Low maintenance

- Energy efficient

- Cost-effective installation

- High ROI

Use Cases of Composite Pipes & Success Stories

GRP, GRE, and GRV pipes are popularly used in various use cases. In this section, we brought you some helpful examples of where each saved a project:

GRP Pipe: A Case of Desalination Plant

GRP pipes are used in saline conditions for seawater intakes and brine discharge, where resistance matters the most. These pipes could decrease the need for maintenance in hard-to-access marine environments.

GRP Pipe: The Firewater and Hydrocarbons Transmission

GRE pipes are resistant to high temperatures due to the choice of epoxy resin matrix. Also, they can handle firewater and hydrocarbons in high-pressure oil and gas systems.

GRV Pipe: Used for Chemical Processing Plant

GRV pipes can be used where aggressive media like acids and alkalis require resistance pipes with no extra coating. While their smooth inner surface reduces the pumping energy, it can increase the flow rate in all directions.

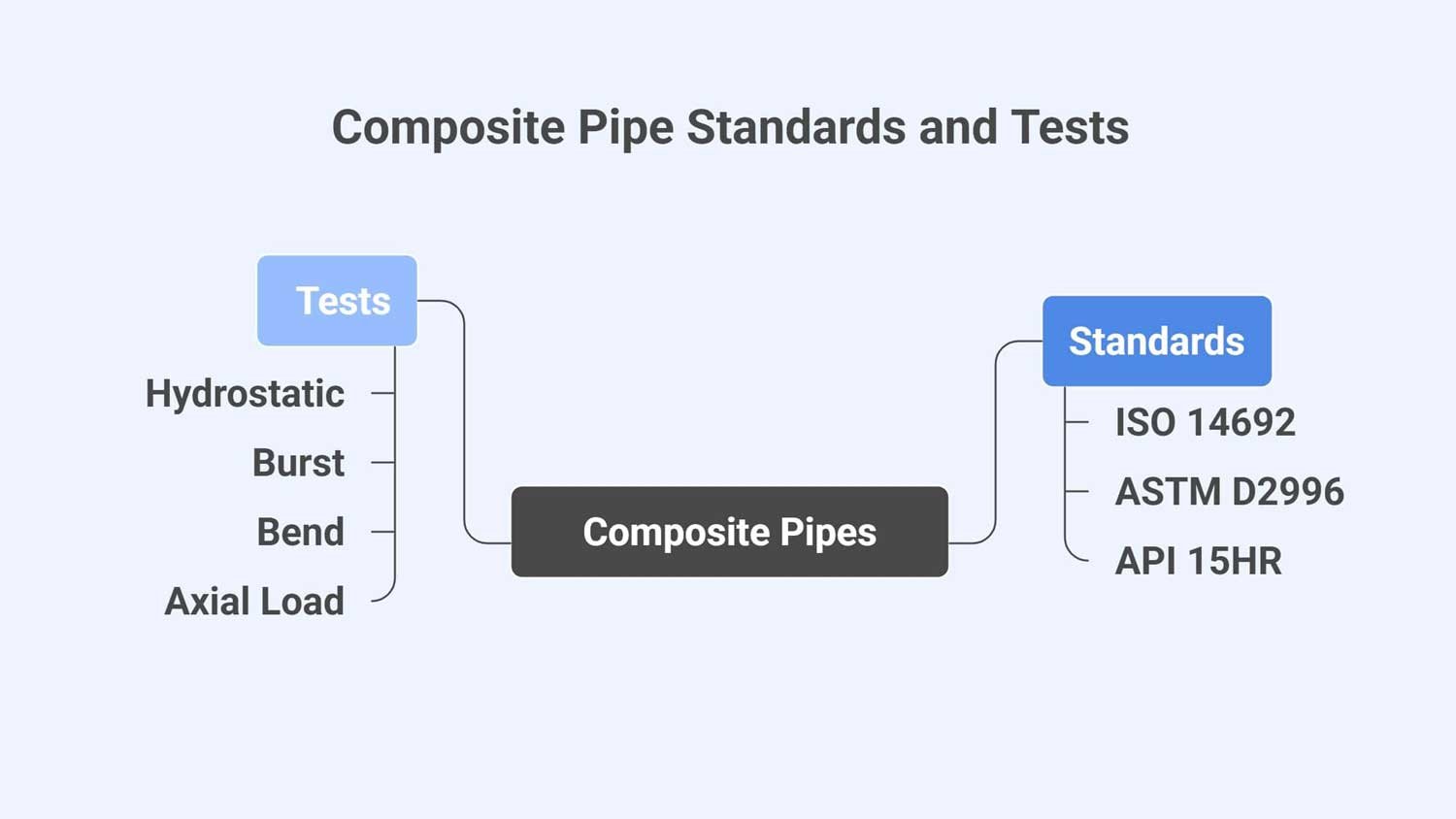

What Standards Do Composite Pipes Follow? And What Tests Do They Pass?

Composite pipes are manufactured and tested to be aligned with international standards such as ISO or ASTM. Check standards and tests below:

- ISO 14692: This can be used for design, manufacturing process, installations, and further testing in glass-reinforced plastic pipes in various use cases.

- ASTM D2996: This one shows how filament winding should be operated to produce pipes for the global market.

- API 15HR: This standard indicates how pipes should be designed and manufactured in diverse pressure ratings.

Also, testing includes:

- Hydrostatic: Tests the pipe under different pressures to check if there’s a leak or a crack.

- Burst: Indicates the maximum pressure the pipe can resist under till it breaks.

- Bend: Assesses the pipe’s flexibility and resistance to bending.

- Axial Load: Evaluates the pipe’s capacity to withstand lengthwise stresses.

Line Core Pipe Group: Leaders in GRP, GRE & GRV Non-Metallic Pipe Solutions

Have you been looking for durable and well-structured GRP, GRE, or GRV pipelines?

Line Core Pipe Group is your reliable partner, not only for design and supply, but also in after-sales support and customization pipelines to your project’s requirements. We provide various industrial applications such as oil & gas, water treatment, chemical processing, and infrastructure.

- ISO-compliant products

- Expert engineering consultation

- Worldwide delivery and support

Contact our team at Line Core Pipe Group today to give you a quote based on your project. Ask for a datasheet or consultation to learn how our team shapes your desired piping system!

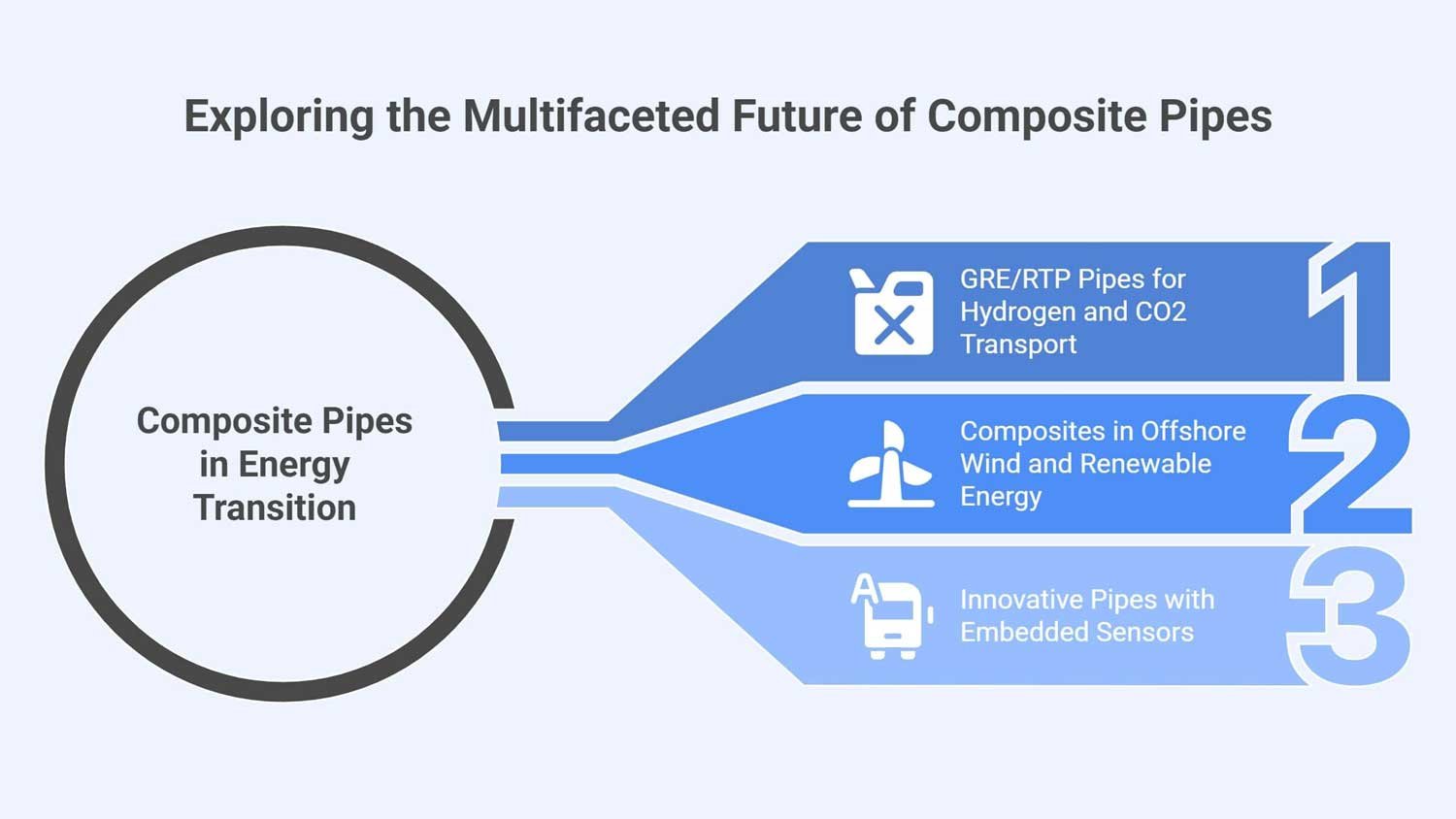

An Overview of the Future of The Industry: Composite Pipes in Energy Transition

Composite pipes have become one of the most popular choices in piping systems. The energy transition issues made manufacturers concerned about how to address the problems for the next generation. Here are three solutions:

GRE/RTP Pipes for hydrogen and CO2 Transport

Due to the durability of the GRE and RTP pipes, they can be used to transport hydrogen and CO22, which may reduce the carbon emissions that walk through the road of sustainability. (Source: Future Pipe)

Composites in Offshore Wind and Renewable Energy

In offshore sites and renewable constructions, it’s the lightweight and corrosion-free nature of composite pipes that makes them highly recommended while decreasing the need for pumping energy.

Innovative Pipes with Embedded Sensors

Smart composites equipped with sensors enable real-time control of parameters such as pressure and temperature to improve the system’s efficiency and ease of proactive maintenance for energy systems.

Conclusion

Non-metallic pipes are surpassing traditional metal pipes due to their exceptional performance under harsh conditions. Composite pipes, as reliable pipelines, are used in various industries to ease the handling, transportation, and installation due to their lightweight and specific jointing methods. FRP family, in a more specific view, reduced the need for repairs caused by corrosion or normal cracks of metal pipes. The selection of these pipes can decrease the overall costs.

FAQs

1- How do composite pipes compare to metal pipes?

Composite pipes are lighter than metal pipes. Their corrosion resistance allows them to reduce the need for costly maintenance.

2- What industries use composite pipes?

Composite pipes are used in industries like oil & gas, water treatment, chemical processing, infrastructure, and desalination plants.

3- How long do composite pipes last?

Composite pipes can last over 50 years in certain conditions.

about

The Author

Farshid Tavakoli is a seasoned professional in engineering and international trade. Holding degrees in Electrical Engineering, Mechatronics, and a Doctorate in Business Administration (DBA) from the University of Lyon, he also has a strong background in industrial automation and production line technologies.

For over 17 years, he has led an international trading company, gaining deep expertise in commercial solutions tailored to industrial needs. With more than 8 years of active involvement in infrastructure development, he specializes in the supply of electromechanical equipment for water and wastewater treatment plants and transfer projects.

Together with comapny expert team, he now provides consultancy and integrated solutions for sourcing and implementing complex infrastructure projects across the region.