Do you know how many piping projects fail due to the wrong pipeline selection every year? Fiber Reinforced Plastic (FRP) pipes include different types such as GRP, GRV/GRVE, or GRE that each may support various use cases from oceans to deserts. Nowadays, contractors turn to plastic pipes with lightweight and perfect corrosion resistance over traditional metallic pipes, which last 40 years under the best conditions.

GRP pipes are cost-effective and appropriate for semi-corrosive, low-pressure systems. GRV pipes are perfect for industrial use cases because they tolerate temperature changes with superior chemical resistance. GRE pipes are useful for oil, gas, and offshore systems due to their top-notch strength, pressure, and thermal resistance. Performance requirements, resin type, and environmental conditions affect selection.

In this article, we’ll dive into the comparison of these three pipelines via their notable characteristics for engineers and project managers to choose the proper pipeline paired with their project demands.

GRP, GRV, and GRE Pipes: How Do They Differ?

The GRP, GRV, and GRE pipes are all types of fiberglass-reinforced plastic (FRP) pipes, but they play such different roles due to their thermosetting resin type.

Core Differences: GRP pipes are made from isophthalic polyester resin for general piping use cases. Otherwise, GRV pipes come from a vinyl ester resin base to resist under highly aggressive chemicals, and GRE pipes with epoxy resin shine in high-pressure and warmer conditions.

Below is a comprehensive comparison of these three pipelines based on their distinctive properties:

| Parameter | GRP Pipes | GRV/GRVE Pipes | GRE Pipes |

|---|---|---|---|

| Resin Type | Isophthalic Polyester | Vinyl ester | Epoxy |

| Max Temperature | 50°C to 75°C | 75°C to 100°C | Up to 110°C or 120°C |

| Pressure Resistance | Up to 16 bar (design-dependent) | Up to 16 bar (design-dependent) | Up to 32 bar (design-dependent) |

| Corrosion Resistance | Good (non-aggressive fluids, e.g., water) | Better (handles acids, alkalis) | Excellent (resists hydrocarbons, strong acids) |

| Fire Resistance | Good (Class 1 flame spread, 5–25) | Good (Class 1 flame spread, 5–25) | Good (Class 1, enhanced with coatings) |

| Cost Efficiency | Most cost-effective | Moderate cost | Most expensive |

| Industry Fit | Potable water, sewer, drainage, marine ballast | Industrial chemicals, wastewater, desalination | Oil & gas, offshore platforms, high-pressure systems |

| Weight | Lightweight (30% lighter than steel) | Lightweight (similar to GRP) | Lightweight (slightly heavier due to epoxy) |

| Tensile Strength | 100–150 MPa (moderate) | 150–200 MPa (higher) | 200–250 MPa (highest) |

| Chemical Resistance Profile | Limited to mild chemicals (e.g., potable water) | Moderate (acids, alka

lis, seawater) |

Broad (strong acids, alkalis, hydrocarbons) |

| UV Resistance | Moderate (requires UV coating) | Moderate (requires UV coating) | Good (better with protective topcoat) |

| Service Life | 30–50 years (with proper maintenance) | 40–50 years (with proper maintenance) | 50+ years (with minimal maintenance) |

An Overview of Glass-Fiber Reinforced Pipe Types

GRP, GRE, and GRV pipes are types of FRP pipes; each is used in both industrial and rural applications due to their different resin base to match specific project demands. Differences include:

GRP (Glass Reinforced Plastic) Pipes

GRP pipes are produced from glass fiber reinforced with isophthalic polyester resin and are primarily used in potable water, sewer systems, drainage, and marine ballast systems. These general uses come from properties like cost-effectiveness, corrosion resistance, and lightweight.

GRV/GRVE (Glass Reinforced Vinyl Ester) Pipes

The resin type used in GRV pipes is vinyl ester, which provides a chemical resistance to acids and alkalis over metallic pipes or other types of composite alternatives. So, they’re counted as top choices in industrial chemical transmissions, wastewater treatment, and desalination plants.

GRE (Glass Reinforced Epoxy) Pipes

GRE pipes are manufactured by glass fibers and epoxy resin to create superior tolerance of pressure and temperature up to 32 bar and 120°C. They include a perfect performance for oil & gas pipelines, offshore platforms, and high-pressure systems.

FRP and RTRP: How Are They Related To GRP, GRV/GRVE, And GRE Pipes?

To reach a better understanding of GRP, GRV, and GRE pipes, the terms FRP and RTRP ease the way through classification of each. Let’s break them into vivid explanation of what exactly they are and how to define these pipelines:

FRP: Fiber Reinforced Plastics

FRP is known as an umbrella for a composite mix of polymer matrix (mostly thermosetting resins like polyester, vinyl ester, or epoxy) with glass fibers, carbon, or aramid as reinforced fibers.

The glass fiber type of FRP with each of the resin bases makes GRP, GRV, or GRE pipes to act as corrosion-resistant and long-lasting pipelines over decades under harsh conditions.

RTRP: Reinforced Thermosetting Resin Pipe

As a substance of FRP, RTRP is counted as a pipe with thermosetting resin matrices (when hardened, there’s no chance to reshape them) used in oil & gas, water supply systems, and marine conditions.

Thus, GRP, GRV, and GRE pipes all go through the RTRP classification due to the thermosetting resin base and glass fiber used for performance requirements.

Mechanical Property Comparison of GRP vs GRV/GRVE vs GRE Pipes by Resin

Mechanical characteristics of these three pipelines can be varied by the resin base used in each, while making them top choices of various applications from harsh chemical handling to oil and gas transmissions.

For instance, GRP is the most-used one with cost-effective and durable properties, while GRV pipes include balanced properties with high chemical resistance. Last, GRE pipes resist under heavy loads (200–250 MPa) and a wide range of temperature tolerance (40-120°C). Check table below for more detailed information:

| Property | GRP (Polyester) | GRV/GRVE (Vinyl ester) | GRE (Epoxy) |

|---|---|---|---|

| Tensile Strength (MPa) | 100–150 (Low-stress, sewer systems) | 150–200 (desalination) | 200–250 (oil & gas) |

| Shear Strength (MPa) | 50–70 (non-aggressive) | 70–90 (industrial chemicals) | 90–110 (offshore platforms) |

| Modulus of Elasticity (GPa) | 8–12 (municipal water) | 12–15 (wastewater) | 15–20 (high-pressure) |

| Elongation (%) | 2–3 (Flexible, drainage) | 1.5–2.5 (chemical processing) | 1–2 (Rigid, marine systems) |

| Heat Distortion Temp (°C) | 50–75 (potable water) | 75–100 (desalination) | 100–120 (oil & gas) |

- Mechanical Insight: ScienceDirect Highlight that due to the high strength of E-glass used in FRP pipes, they contain a lower modulus of elasticity than traditional pipelines like steel or concrete.

Manufacturing Methods and Material Composition Of GRP, GRV, And GRE Pipes

FRP pipes are manufactured via several methods to match both large and small scales of production with composite materials such as glass fibers and thermosetting resin matrix.

As we’ve clarified each resin type and their impact on each pipe, let’s dive into different types of glass fibers and manufacturing methods:

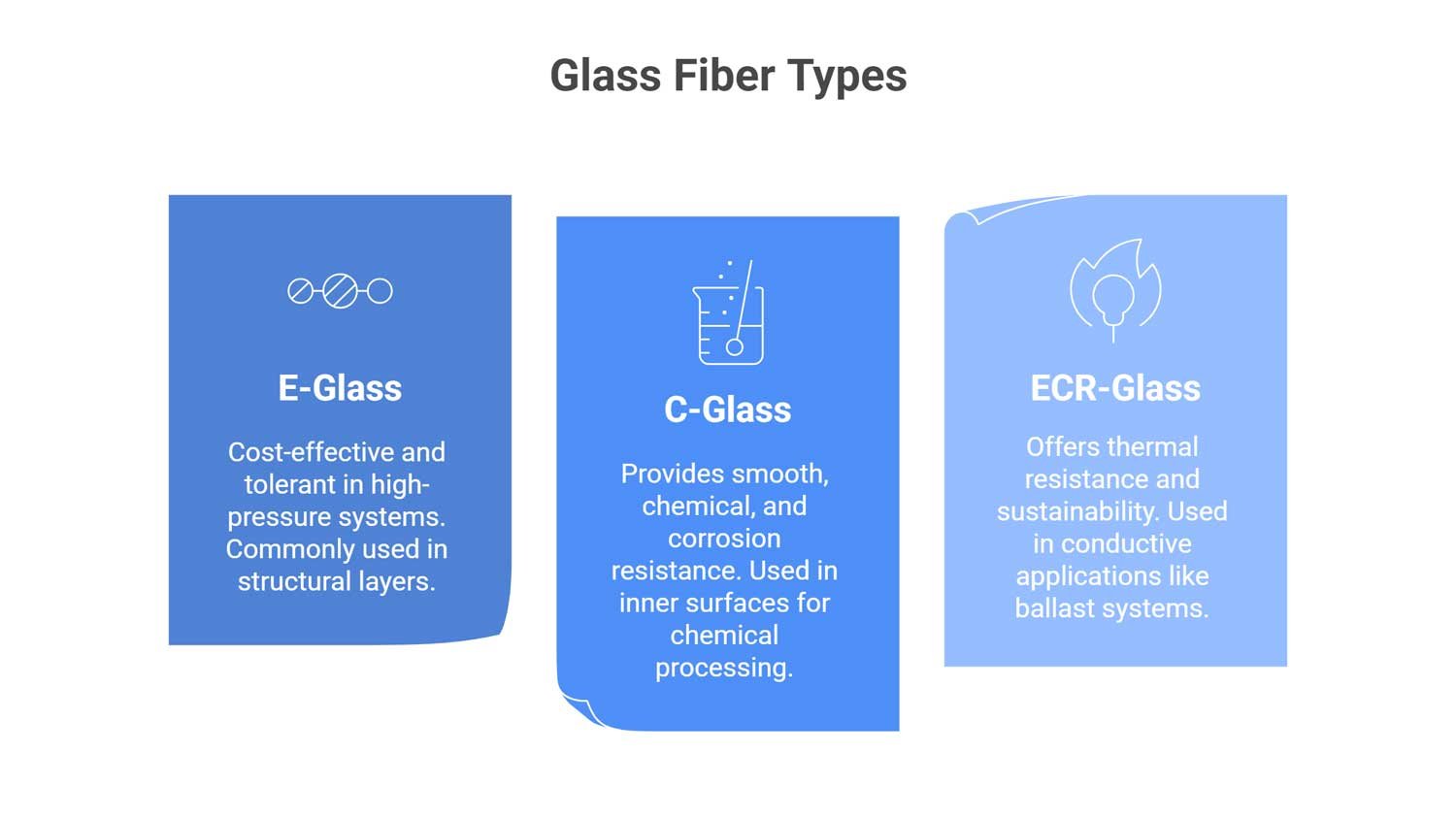

Types of Glass Fiber Used

Glass fiber used in FRP pipes includes three central types:

E-Glass (Electrical Glass): This type is commonly used in all three pipelines’ structural layers due to the cost-effectiveness and perfect tolerance in high-pressure systems.

C-Glass (Chemical Glass): Technically, in FRP pipes, the smooth and chemical and corrosion resistance of the inner surface comes from C-glass fibers and specific resin matrix for chemical processing and desalination.

ECR-Glass (Electrical & Corrosion Resistant Glass): Used due to the thermal resistance and sustainability in conductive applications like ballast systems or oil & gas pipelines.

Manufacturing Processes

To match all projects’ specific demands, there are three methods, from the most-used type, like filament winding, to the hand lay-up method for special diameter sizes.

- Filament Winding: Via standards like ASTM D2996, glass fibers are twisted over a mandrel to create a strong pipe for high-pressure systems like oil & gas or chemicals.

- Centrifugal Casting: To shape a smooth pipe via spinning resin and glass fibers around for applications like water treatment where chemical resistance matters.

- Hand Lay-Up: Layers are made manually to make custom pipes and fittings in industrial piping systems.

Pipe Construction & Layered Design

There are multiple choices for how GRP, GRV, or GRE pipes are designed by barrier layers, inner liners, and other additive layers.

Inner Liner (Smooth, Resin-Rich)

In potable water (GRP), oil & gas (GRE), and chemical processing (GRV) applications, a resin layer is added to create a smooth and corrosion-resistant inner surface for reduction of pumping cost and long-term performance.

Chemical Barrier Layer Option and Outer UV/Topcoat

Coating and extra layers typically work for protecting pipes against aggressive fluids and UV light in irrigation or desalination plants where degradation or cracks may happen.

Structural Wall (Glass Roving Pattern)

E-glass or ECR-glass rovings provide strength, with GRE offering the highest tensile strength for high-pressure systems.

Pipe Fittings and Jointing Methods of Each Pipeline

GRP, GRV, and GRE pipes are joined via different methods to fit various conditions, whether in seismic zones or desalination plants.

Standard Fittings

Fittings such as elbows, tees, reducers, couplings, flanges, and caps guarantee compatibility because they are composed of the same glass fiber and resin as the pipes.

GRE supports high-pressure oil and gas systems, GRV/GRVE is appropriate for chemical processing, and GRP fittings are reasonably priced for potable water.

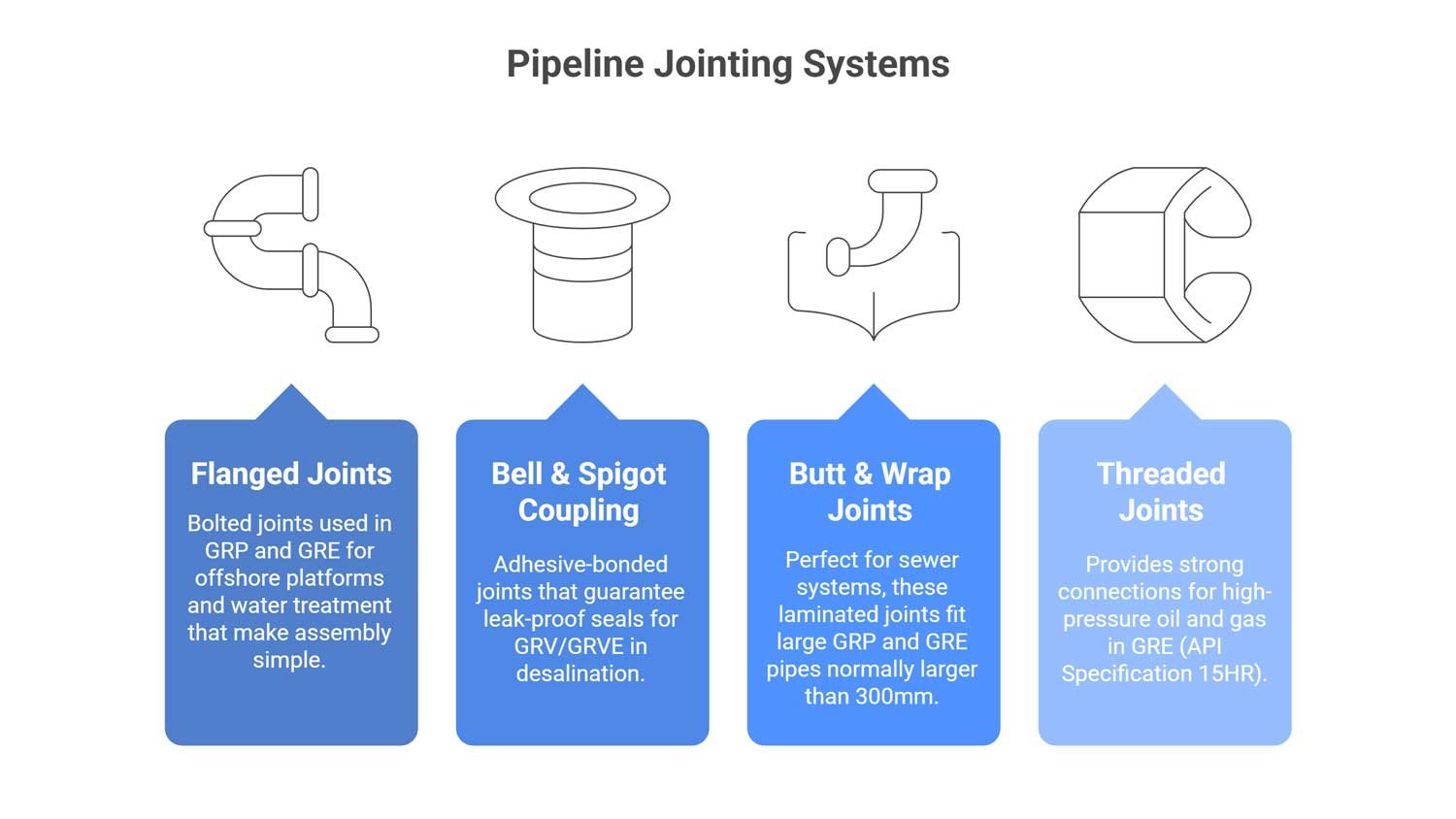

Types of Jointing

These pipelines include several jointing systems such as flanged, bell & spigot, or REKA joints. Here are some examples of each used for GRP, GRV, and GRE pipes.

- Flanged joints (ANSI, BS, DIN): bolted joints used in GRP and GRE for offshore platforms and water treatment that make assembly simple.

- Bell & Spigot Coupling: Adhesive-bonded joints that guarantee leak-proof seals for GRV/GRVE in desalination.

- Butt & Wrap Joints: Perfect for sewer systems, these laminated joints fit large GRP and GRE pipes normally larger than 300mm.

- Threaded Joints: Provides strong connections for high-pressure oil and gas in GRE (API Spec 15HR).

What Are the Main Installation Methods of FRP Pipes?

Specific guidelines are needed for both aboveground and underground installations of these fiberglass-reinforced plastic (FRP) pipes, which are made with epoxy resins, vinyl ester, or isophthalic polyester, in order to preserve their structural integrity and resistance to corrosion.

Under-Ground Installation

To support GRP, GRV/GRVE, and GRE pipes and avoid settlement in water treatment lines or sewer systems, use compacted granular material, such as sand. Consider that bell and spigot or butt and wrap joints are crucial for desalination pipelines because they avoid pipes’ movement.

Aboveground Installation

To avoid sagging, specifically for GRE in high-pressure oil and gas systems, install supports every three to six meters. Also, to prevent degradation in aboveground water treatment systems, apply UV-resistant coatings to GRP and GRV/GRVE pipes.

Installation Standards and Protocols for Manufacturers

Follow ASTM D2996 for pipes made of filament winding process and ISO 14692 for oil and gas systems. To guarantee long-lasting performance, follow the manufacturer’s instructions for hydrostatic testing and jointing methods inspections.

Non-Destructive Testing (NDT) & Traceability

To achieve long-term pipeline performance under certain conditions, FRP pipes should pass several testing methods such as visual inspection or ultrasonic testing. Here is a comprehensive table for these testing methods to reach global standards:

| Method | Description | Application Example |

|---|---|---|

| Barcol Hardness | Measures resin hardness (30–50) | GRP in potable water, GRE in oil & gas |

| Ultrasonic Testing (UT) | Detects internal voids/delamination | GRV/GRVE in desalination |

| Thermography | Identifies thermal anomalies | GRE in offshore platforms |

| Acoustic Emission | Monitors stress-induced cracks | All pipes in chemical processing |

| Radiography | Uses X-rays to detect internal flaws | GRE in high-pressure systems |

| Eddy Current Testing | Detects surface and near-surface defects | GRP in water treatment |

- Engineering Insight: : Ultrasonic testing is used during the installation process to prevent leaks and increase the lifespan following ASTM D1599 standards. (Source: NDT)

Composition Traceability Challenges

Strict quality control is necessary for GRP, GRV/GRVE, and GRE pipes because it can be challenging to ensure consistent resin and glass fiber composition across batches due to differences in raw materials and manufacturing processes.

NDT Standards

Standards always support processes for a global look. In GRP, GRV, and GRE pipes’ manufacturing and installations, the more pipes are certified by these guidelines, the more durable they are in harsh environments.

- ASTM D4161: Beam test for reliable and proper jointing systems selection.

- ASTM D1599: Pressure test for pressure resistance after the installation process.

- ASTM D2412: Stiffness test for pipe rigidity, required for sewer systems and oil & gas pipelines.

Health, Safety & Handling Considerations

Composite plastic pipes are more likely to release fumes or dust that harm workers’ lungs. These risky pollutions come from both resin and glass fibers during the manufacturing, installation, and maintenance process.

Resin Fumes and Fiberglass Dust: PPE Needs

Personnel Protective Equipment (PPE) is required when workers are coping with resin fumes and fiberglass dust in cutting, grinding, or applying layers. PPE includes respirator masks, gloves, and goggles.

For instance, in potable water systems for GRP or GRV pipes, it’s recommended to avoid respiratory irritation through proper masks.

Safe Storage, Lifting, and Transport Practices

For GRV pipes, they should be stored horizontally and away from the sunlight to prevent further deformation or degradation.

The transportation process for all these pipe types is easier than traditional ones due to the flexible jointing methods and lightweight.

Also, for the lifting part, slings and spreader bars avoid uneven pressure distribution in high-pressure systems like chemical processing.

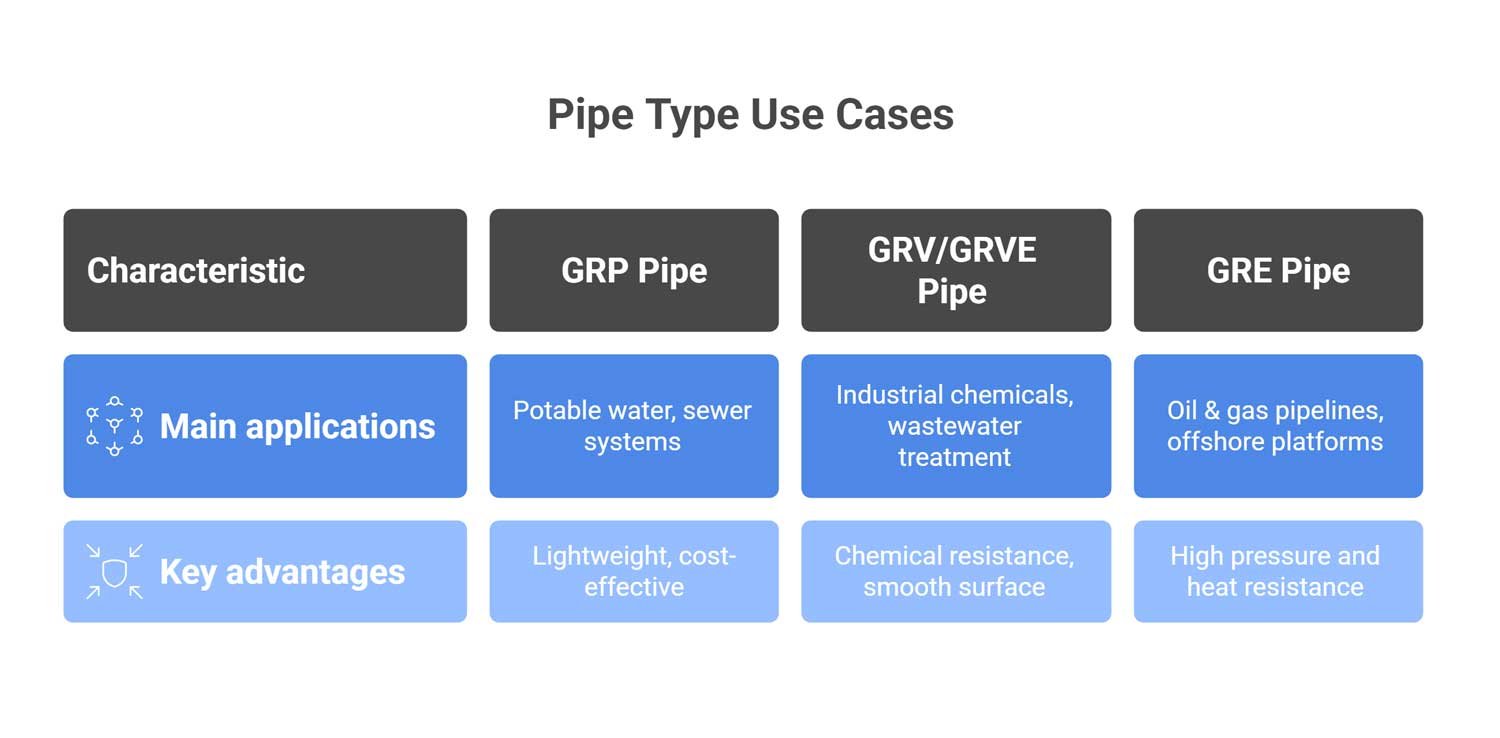

Use Cases Scenarios by Pipe Type: from Sewer Systems to Irrigation Networks

The applications of each GRP, GRV, and GRE pipe rely on their specific properties. However, all of them can resist under certain conditions; each may show a magnificent performance in its special use cases.

GRP Pipe Applications

Due to their lightweight (30% lighter than steel) and cost-effectiveness, they’re generally used in potable water, sewer systems, drainage, and marine ballast systems where non-aggressive fluids flow.

GRV/GRVE Pipes Applications

GRV pipes create a smooth and chemical-resistant inner surface to reduce the pumping costs and make them perfect for industrial chemicals, wastewater treatment, and desalination plants where acids and alkalis require high-resistance pipes.

GRE Pipes Applications

GRP pipes are used for harsh and aggressive environments like oil & gas pipelines, offshore platforms, and high-pressure systems to show how remarkably superior they are in pressure (up to 32 bar) and heat resistance (up to 120°C).

How Do GRP and GRE Pipes Act in Ship and Marine Conditions?

GRP and GRE pipes are both used in marine applications, whether in tankers, offshore systems, or ship ballast systems, due to their exceptional resistance to corrosion, pressure, or fire.

Resistance of GRP and GRE

GRP pipes resist up to 75°C, 16 bar of pressure, potable water corrosion, and a basic range of fire retardant, while GRE pipes tolerate 32 bar of pressure, up to 120°C for engine rooms, and class 1 of fire resistance with coating layers in hydrocarbon transmissions.

Use Cases of GRP and GRE

Also, GRE pipes transport fuels by tankers due to high-pressure systems tolerance, used in offshore rigs under certain conditions, while GRP pipes are used as a cost-effective choice in drainage and ballast water systems.

Lifecycle Performance and Operational ROI

However, GRP, GRV, and GRE pipes contain a higher initial cost than their alternatives; they last way longer with less need for maintenance or repairing. Below, we clarify how they require maintenance, lower the pumping cost, and extend their service life.

Need for Maintenance

- GRP: Needs little maintenance and recurring checks for UV deterioration in drinking water systems.

- GRV/GRVE: The higher chemical resistance allows moderate maintenance and periodic cleaning for desalination.

- GRE: Because of its strong resistance to corrosion, GRE requires little upkeep for gas and oil and only occasionally needs repairs.

Service Life

When installed correctly, protected from UV rays, and in accordance with ASTM D2992 standards, all pipe types have a service life of more than 50 years, which maximizes return on investment in long-term projects.

Efficiency of Pumping and Flow Properties

A smooth inner liner in GRP pipes lowers energy expenses with high pumping efficiency for sewer systems. In GRV pipes, wastewater flow includes a high rating that balances chemical resistance and efficiency. GRE pipes improve the functional efficiency through superior flow in high-pressure oil and gas systems.

Standards & Certifications

Standards and guidelines indicate how GRP, GRV/GRVE, and GRE pipes should be manufactured, installed, or cured. There are many notable global and national standards for these pipelines that we mention some of them below:

Key Standards and Certifications

- ISO 14692: Includes design, testing, and installation of GRE pipes for petroleum and natural gas industries to shape a high-pressure tolerance.

- ASTM Standards: D2996 (filament-wound pipes), D2997 (centrifugal cast), D4161 (joint testing), and D5685 (FRP pipes) apply to GRP and GRV/GRVE for water treatment.

- AWWA C950: Indicate the requirements for GRP pipes in potable water and wastewater systems via hydrostatic testing.

- API SPEC 15HR: Shows how GRE pipes are qualified for high-pressure applications.

- NSF/ANSI 14, 61: Used for GRP pipes to contain safety standards for potable water with focus on material health and quality.

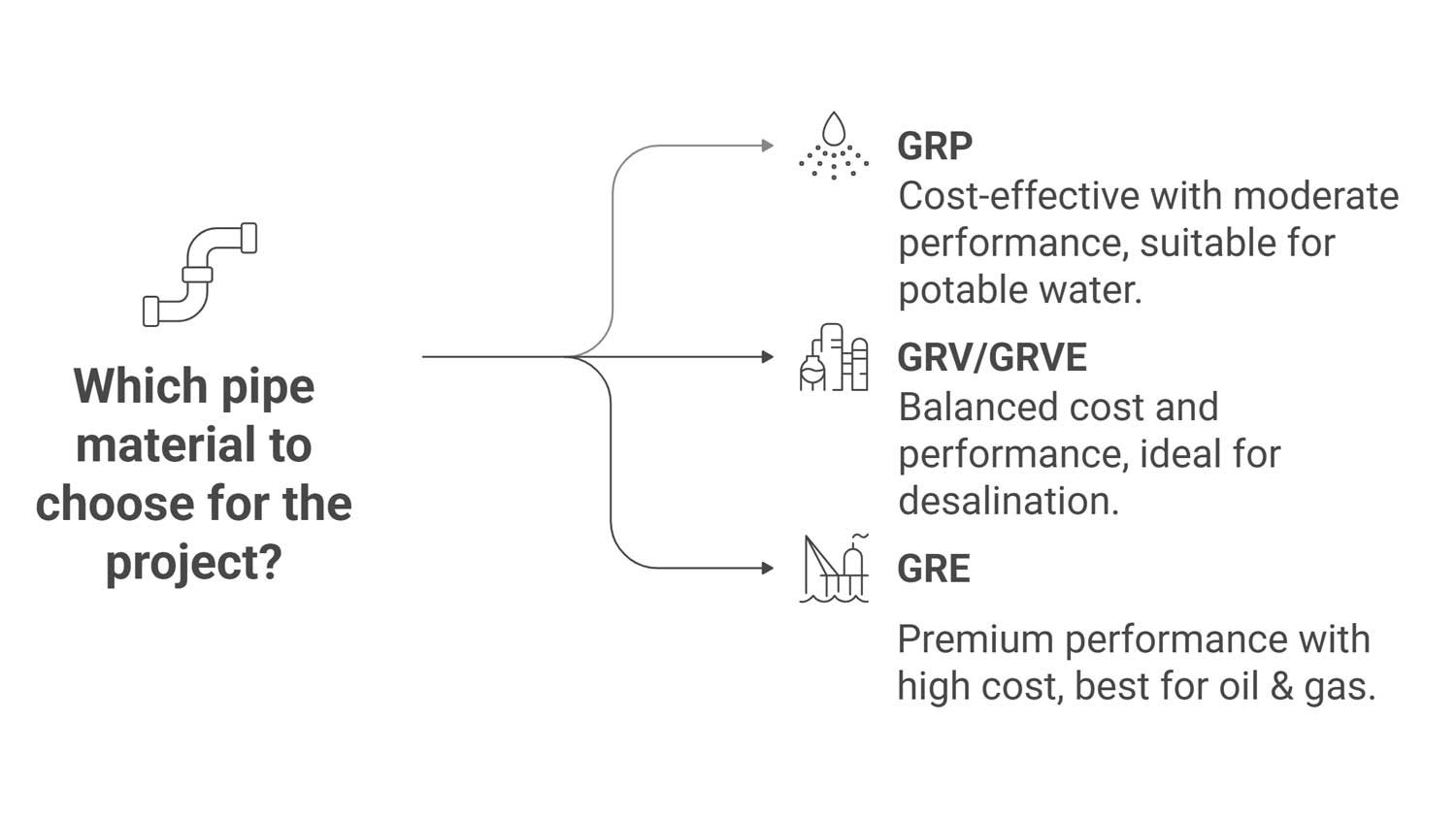

GRP vs GRV vs GRE – Which Pipe to Choose?

All details of your project will inform which composite pipe is the greatest. Here is a decision-making pattern for GRP, GRV, and GRE pipes.

Engineering Considerations: Temperature, Corrosion, and Fire/UV Resistance

First check each for their resistance level of corrosion, chemicals, fire, temperature, and pressure:

GRP Pipes: Show reliable and cost-effective performance for moderate temperatures (below 60°C) and non-aggressive environments such as drainage or potable water.

GRV/GRVE Pipes: Due to their superior chemical resistance and temperature tolerance of about 90°C, GRV pipes work better in environments with acids, alkalis, or other aggressive solvents.

GRE Pipes: They are the best option for high-pressure or high-temperature applications, because of its mechanical strength and thermal endurance, notably offshore or oil and gas areas.

Budget vs performance priorities

Lastly, compare the initial investment to the long-term results. When the risk of failure is expensive, GRE is the best one yet long-lasting, GRV provides a high chemical resistance, and GRP is a cost-effective choice for general uses.

Final Thought

The proper selection of FRP pipes will pave the way of long-term performance over decades with low maintenance requirements. GRP, GRV/GRVE, and GRE pipes are subsets of FRP and RTRP pipes that significantly are used in various applications due to their lightweight, corrosion resistance, and cost-effectiveness. Each may shine in specific uses like water supply, wastewater management, marine systems, and oil & gas pipelines.

FAQs

1- Which pipe is best for high-pressure applications?

GRE pipes are best for high-pressure applications (up to 32 bar) to make them perfect for oil & gas and offshore platforms due to their epoxy resin strength.

2- How long do these pipes last?

With proper use and maintenance, all GRP, GRV/GRVE, and GRE pipes can last over 50 years, per ASTM D2992 standards.

3- Are these pipes corrosion-resistant?

Yes, all are corrosion-resistant, GRE include a good resistance against aggressive fluids like hydrocarbons, GRV/GRVE for seawater, and GRP for non-aggressive water.

about

The Author

Farshid Tavakoli is a seasoned professional in engineering and international trade. Holding degrees in Electrical Engineering, Mechatronics, and a Doctorate in Business Administration (DBA) from the University of Lyon, he also has a strong background in industrial automation and production line technologies.

For over 17 years, he has led an international trading company, gaining deep expertise in commercial solutions tailored to industrial needs. With more than 8 years of active involvement in infrastructure development, he specializes in the supply of electromechanical equipment for water and wastewater treatment plants and transfer projects.

Together with comapny expert team, he now provides consultancy and integrated solutions for sourcing and implementing complex infrastructure projects across the region.