In the world of piping systems, proper pipeline selection can save the entire project while guaranteeing durable performance with no leaks. Glass Reinforced Plastic (GRP) pipes and Unplasticized Polyvinyl Chloride (UPVC) pipes are widely used in various piping projects, including water distribution, industrial, and rural systems. But what’s the best option to meet your project’s demands? Which characteristics are essential in pipe material comparison?

GRP pipes and UPVC pipes are both widely used in various applications, such as water and wastewater systems, as well as chemical and industrial transmission. GRP pipes shine in corrosive and high-pressure environments due to their composite nature and exceptional design. Although UPVC pipes are preferred due to their lower initial cost and good resistance to corrosion or handling medium pressures, GRP pipes are superior due to their lower maintenance needs and longer lifespan.

GRE pipe specification infographic (source: pipelinecoregroup.com)

In this article, we’ll provide a comprehensive comparison of GRP and UPVC pipes for engineers, contractors, and procurement managers to help them choose the most durable and well-designed pipeline for their construction projects.

Before exploring how GRP and UPVC pipes change the game of piping systems, let’s review all the comparison factors at a glance:

| Parameter | GRP Pipes | UPVC Pipes |

|---|---|---|

| Material Composition | Glass fiber reinforced polymer matrix | Unplasticized polyvinyl chloride |

| Corrosion Resistance | Excellent, unaffected by most chemicals and harsh environments | Good, but can degrade under UV exposure or extreme chemical conditions |

| Chemical Resistance | Superior, resists acids, alkalis, and solvents | Good for household chemicals, less resistant to aggressive chemicals |

| Pressure Handling | High, suitable for high-pressure systems (up to 32 bar or more) | Low to medium, typically up to 16 bar |

| Temperature Tolerance | High, up to 120°C or more depending on resin type | Low, typically up to 60°C (suitable for cold water) |

| Installation Ease | Requires skilled labor and specialized techniques (e.g., filament winding) | Easy, uses standard tools and solvent cement joints |

| Maintenance Requirements | Low, highly durable with minimal upkeep | Moderate, requires periodic checks for degradation |

| Lifespan | 50–100 years depending on conditions | 25–50 years depending on environment |

| Cost-effectiveness | Higher initial cost, but lower long-term costs due to durability | Lower initial cost, higher maintenance/replacement costs over time |

| Environmental Impact | More sustainable, recyclable, longer lifespan | Less sustainable, shorter lifespan, recycling challenges |

| Weight | Lightweight but slightly heavier than uPVC | Very lightweight, easier to transport and handle |

| Pipe Fittings Compatibility | Compatible with specialized GRP fittings, may require custom solutions | Widely compatible with standard PVC fittings, readily available |

What Exactly Are GRP and UPVC Pipes? And How Are They Manufactured?

To achieve a better understanding of the comparison between GRP pipes and UPVC pipes, their materials and manufacturing processes lead you to recognize their crucial differences.

Glass Reinforced Plastic (GRP) pipes: referred to a blend of glass fibers and a resin matrix that provides durability and corrosion resistance in harsh and high-pressure environments through methods such as filament winding or centrifugal casting.

Unplasticized polyvinyl chloride (UPVC) pipes: manufactured from UPVC resin and additives, such as stabilizers or pigments, which are used to customize the result through the extrusion method. This process involves heating, melting, forming, cooling, cutting, and sizing the material into the desired shapes.

Key Comparison Factors of GRP and UPVC Pipes

As the central part of the comparison between GRP and UPVC pipes, this section shows how these two pipelines differ in characteristics such as corrosion resistance, pressure handling, or temperature tolerance:

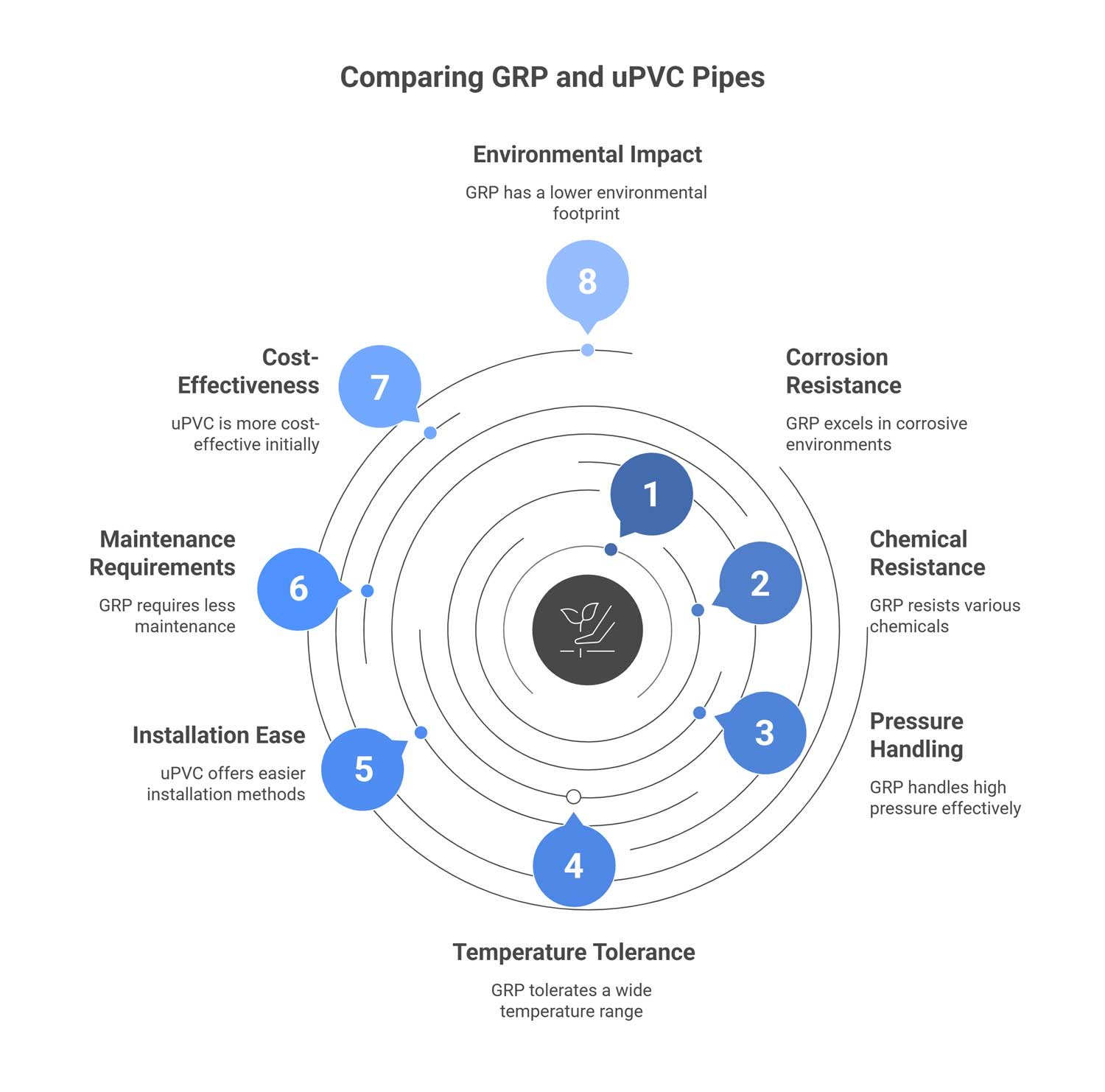

Corrosion Resistance

GRP pipes, with a polyester resin base and composite nature, create a significant barrier against corrosion, as noted in Environmental Expert, whether electrochemical or chemical, in saline or acidic environments. This makes them perfect for wastewater treatment systems and marine applications.

UPVC pipes are mainly used in potable water, drainage, and sewerage systems due to their non-metallic composition. However, they may degrade under harsh conditions, such as exposure to concentrated acids or ultraviolet (UV) light.

Chemical Resistance

GRP pipes with a resin matrix of polyester resist acids, alkalis, solvents, and hydrocarbons in chemical, oil, and gas transmissions, and desalination plants, where they transport fluids without degradation.

In contrast, UPVC pipes include a lighter chemical resistance than GRP pipes to chemicals like strong acids or organic solvents. Recommended applications include less aggressive chemicals like salts or mild acids.

Pressure Handling

Glass fibers in GRP pipes create a unique design to handle high-pressure loads in water transmission, industrial fluid transport, and fire protection networks, while UPVC pipes are ideally used in high-pressure water distribution systems. (Source: ScienceDirect)

However, UPVC pipes may tolerate low to medium pressures, whereas GRP pipes are superior due to their high strength-to-weight ratio in high-pressure systems.

Moreover, research by ScienceDirect shows GRP pipes can handle up to 1 million pressure surge cycles at 0.5 MPa, significantly stronger than UPVC pipes, which may crack after just 100,000 cycles.

Temperature Tolerance

GRP pipes include a wide range of temperature tolerance of -40°C to 80°C, perfect for hot water systems or geothermal piping by specializing the resin base for specific conditions.

While UPVC pipes are used for cold water distribution or irrigation, where the temperature doesn’t get high enough to cause pipes to soften or structural damage.

Installation Ease

GRP pipes are used for various applications via adaptable installation methods and jointing, such as flanged joints or adhesive bonding, in both trenching and trenchless installations.

UPVC pipes, on the other hand, are easy to install, such as mechanical joints or push-fit systems, in residential plumbing or agricultural irrigation plants as a cost-effective choice.

Maintenance Requirements

Due to the durability and corrosion resistance of GRP pipes, they decrease the need for regular maintenance or repairs and last over 50 years under certain conditions. (Source: Scribd) Though in highly corrosive conditions, they mainly require periodic lining.

UPVC pipes also require low maintenance, but the thing is periodic repairs and maintenance contain physical damage, UV degradation, or chemical wear in certain conditions.

Cost-Effectiveness

UPVC pipes are superior in initial costs due to the plastic material over the composite material of GRP pipes. Also, GRP pipes require more energy for the manufacturing process; however, they are a better choice due to their long lifespan and higher ROI.

Environmental Impact

Last but not least, recent trends in piping systems follow sustainable and eco-friendly pipelines such as GRP pipes or UPVC pipes.

The long-term performance of GRP pipes makes them a top choice for corrosive environments, while reducing their environmental footprint and need for replacement. UPVC pipes encounter some issues due to their chloride base for recycling and their shorter lifespan in the same situation compared to GRP pipes.

GRP Pipes vs UPVC Pipes: Pros & Cons Comparison

After discovering each characteristic of GRP and UPVC pipes, let’s weigh their strengths and limitations in applications like water and wastewater systems or chemical transmission.

GRP Pipes’ Pros and Cons

GRP Pipes are known as a top choice for high-pressure flows, corrosive and harsh environments, and temperature-changing conditions. In acidic, UV light exposure (outdoor applications), the resin base of the GRP pipes shines with the least maintenance requirement.

After all, the long lifespan of GRP pipes comes from these fruitful properties that make up the initial cost of the composite material.

| Pros | Cons |

|---|---|

| Exceptional corrosion resistance for chemical plants and marine environments. | Higher initial cost due to complex manufacturing processes. |

| Superior chemical resistance to acids, alkalis, and solvents. | Requires specialized installation, increasing labor costs. |

| High pressure handling up to 300 psi for robust systems. | Limited long-term performance data beyond 50 years. |

| Wide temperature tolerance (-40°F to 180°F) for diverse applications. | |

| Long lifespan (50+ years) with minimal maintenance. | |

| Recyclable, reducing environmental impact. |

UPVC Pipes’ Pros and Cons

UPVC pipes are widely used in several applications, whether industrial or rural, due to their appropriate characteristics such as corrosion resistance, medium-pressure and temperature tolerance, low initial cost, and easy installation methods.

Although UPVC pipes have their magnificent properties in harsh conditions, there are some limitations that lower the demand for UPVC pipelines in long-term projects, as AstralPipes highlights the frequent uses of UPVC pipes in cold water plumbing.

| Pros | Cons |

|---|---|

| Low initial cost, cost-effective for municipal and residential projects. | Limited temperature resistance (up to 140°F), unsuitable for hot water. |

| High installation ease with standard tools like solvent welding. | Susceptible to degradation under UV or harsh chemicals. |

| Good resistance to household chemicals for potable water and drainage. | Shorter lifespan in harsh conditions compared to GRP. |

| Proven 100+ year lifespan in standard conditions. | Recycling challenges due to chlorine content. |

| High pressure handling up to 400 psi. |

GRP Pipes vs UPVC Pipes: Which one’s the best pipeline for your project?

Overall, GRP pipes and UPVC pipes are both used in various piping systems depending on the special project’s demands. However, GRP pipes are a better choice for long-term planning on piping systems due to durability and total cost-effectiveness.

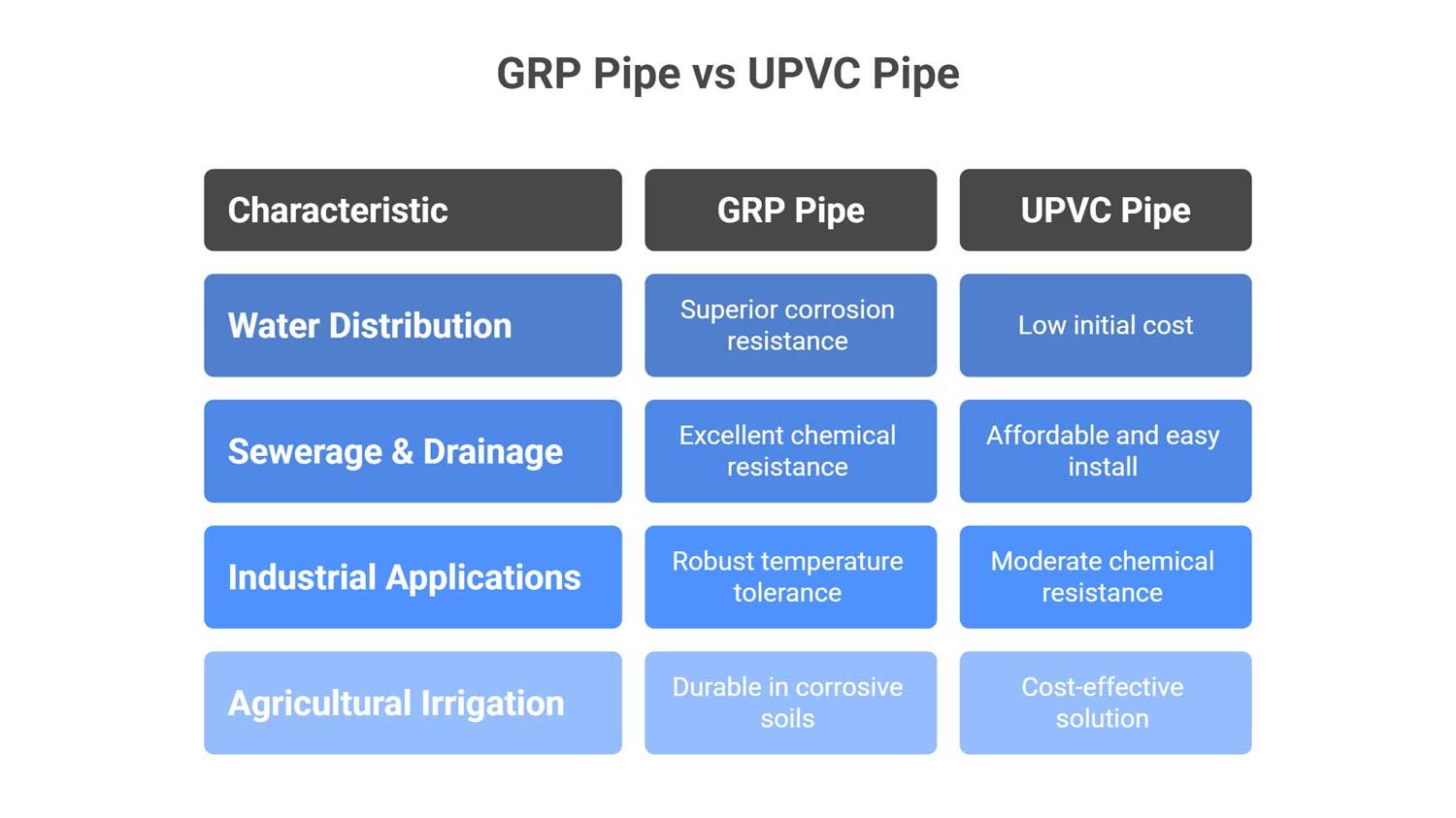

Applications and Suitability Analysis for GRP Pipe vs UPVC Pipe

All around the world, GRP and UPVC pipes are widely used due to their specialized characteristics, such as corrosion resistance, lightweight nature, and durability in various applications.

Water Distribution: Potable and Long-Distance Supply

Both GRP pipes and UPVC pipes are used in water distribution systems, but their performance can vary depending on environmental conditions.

- The superior corrosion resistance of GRP pipes makes them ideal for long-term water supply in harsh soils or saline conditions, with excellent pressure tolerance. In contrast, UPVC pipes, due to their low initial costs and ease of installation, are preferred for potable water in certain conditions.

Sewerage and Drainage: Waste Management

In sewerage and drainage systems, both GRP pipes and UPVC pipes offer characteristics that are shaped by environmental conditions.

- For instance, aggressive sewage and industrial wastewater with high acidity or salinity require a corrosion-resistant pipeline, such as a GRP pipe or UPVC pipe. In this case, GRP pipes are a top choice, as they require less maintenance.

Industrial Applications: High-Demand Settings

In industrial applications involving aggressive fluids, high-temperature and high-pressure tolerance in pipelines is required.

- GRP pipes and UPVC pipes both exhibit excellent performance in this type; however, GRP pipes outperform UPVC pipes in almost all kinds of industrial piping systems, such as chemical processing, oil and gas, and desalination, due to their superior temperature tolerance. UPVC pipes are used in general settings, such as for cooling water or transporting low-corrosion fluids.

Agricultural Irrigation: Longevity and Environment

For agricultural irrigation, GRP (Glass Reinforced Plastic) pipes and UPVC (Unplasticized Polyvinyl Chloride) pipes are evaluated based on their durability, cost, and environmental impact.

- For large-scale irrigation projects and above-ground ones, GRP pipes offer long-term and corrosion-free performance. In contrast, UPVC pipes lose their form under UV light and highly corrosive conditions, which can cause recycling and sustainability issues.

Conclusion

GRP and UPVC pipes both have the potential to change the game of traditional metal pipelines with their corrosion resistance and high-pressure tolerance properties. These characteristics made them ideal for water, wastewater, chemical, or irrigation systems, where durable and sustainable pipelines are the preferred choice. However, GRP pipes are more suitable for use in harsh conditions, while UPVC pipes are generally well-suited for general applications. After all, selecting the right material between GRP and UPVC pipes without considering these factors, such as cost-effectiveness or long lifespan, seems impossible.

FAQs

1- How do GRP pipes perform in corrosive environments?

GRP pipes, with a polyester resin base and composite nature, create a significant barrier against corrosion, whether electrochemical or chemical, in saline or acidic environments.

2- Are UPVC pipes suitable for harsh chemical conditions?

UPVC pipes include a lighter chemical resistance than GRP pipes to chemicals like strong acids or organic solvents.

3- What is the temperature tolerance of GRP pipes?

GRP pipes include a wide range of temperature tolerance of -40°C to 80°C, perfect for hot water systems or geothermal piping by specializing the resin base for specific conditions.

4- What is the temperature tolerance of UPVC pipes?

While UPVC pipes are used for cold water distribution or irrigation, where the temperature doesn’t get high enough to cause pipes to soften or structural damage.

5- How do GRP pipes handle high-pressure systems?

Glass fibers in GRP pipes create a unique design to handle high-pressure loads in water transmission, industrial fluid transport, and fire protection networks.

about

The Author

Farshid Tavakoli is a seasoned professional in engineering and international trade. Holding degrees in Electrical Engineering, Mechatronics, and a Doctorate in Business Administration (DBA) from the University of Lyon, he also has a strong background in industrial automation and production line technologies.

For over 17 years, he has led an international trading company, gaining deep expertise in commercial solutions tailored to industrial needs. With more than 8 years of active involvement in infrastructure development, he specializes in the supply of electromechanical equipment for water and wastewater treatment plants and transfer projects.

Together with comapny expert team, he now provides consultancy and integrated solutions for sourcing and implementing complex infrastructure projects across the region.