The latest trends in piping systems show that GRP pipes are one of the most-used pipelines in various applications. This comes from their composite structure of fiberglass and the corrosion resistance of the resin matrix. GRP pipe types include GRP, GRE, and GRV pipes that each can perform in specific use cases where needed thermal stability, resistance, or cost effectiveness.

In this article, we’ll dive deep into GRP pipes’ manufacturing processes, different types, installations, and standards. Check the table below to reach a quick understanding of GRP pipe types.

| Type of GRP Pipe | Resin System | Strengths | Common Applications | Pressure Rating (PN) | Temperature Resistance | Chemical Resistance |

|---|---|---|---|---|---|---|

| GRP | Unsaturated Polyester | Cost-effective, good for standard use | Water supply, sewerage, irrigation | PN 1 – PN 25 | Up to 60°C | Moderate (acids, alkalis) |

| GRV/GRVE | Vinyl Ester | High chemical resistance, durable | Chemical plants, desalination, wastewater | PN 10 – PN 32 | Up to 80°C | High (acids, salts) |

| GRE | Epoxy | High pressure and temperature resistance | Oil & gas, offshore, high-pressure systems | PN 16 – PN 40 | Up to 120°C | Excellent (hydrocarbons) |

Now, let’s check out how GRP pipes are classified by resin type first:

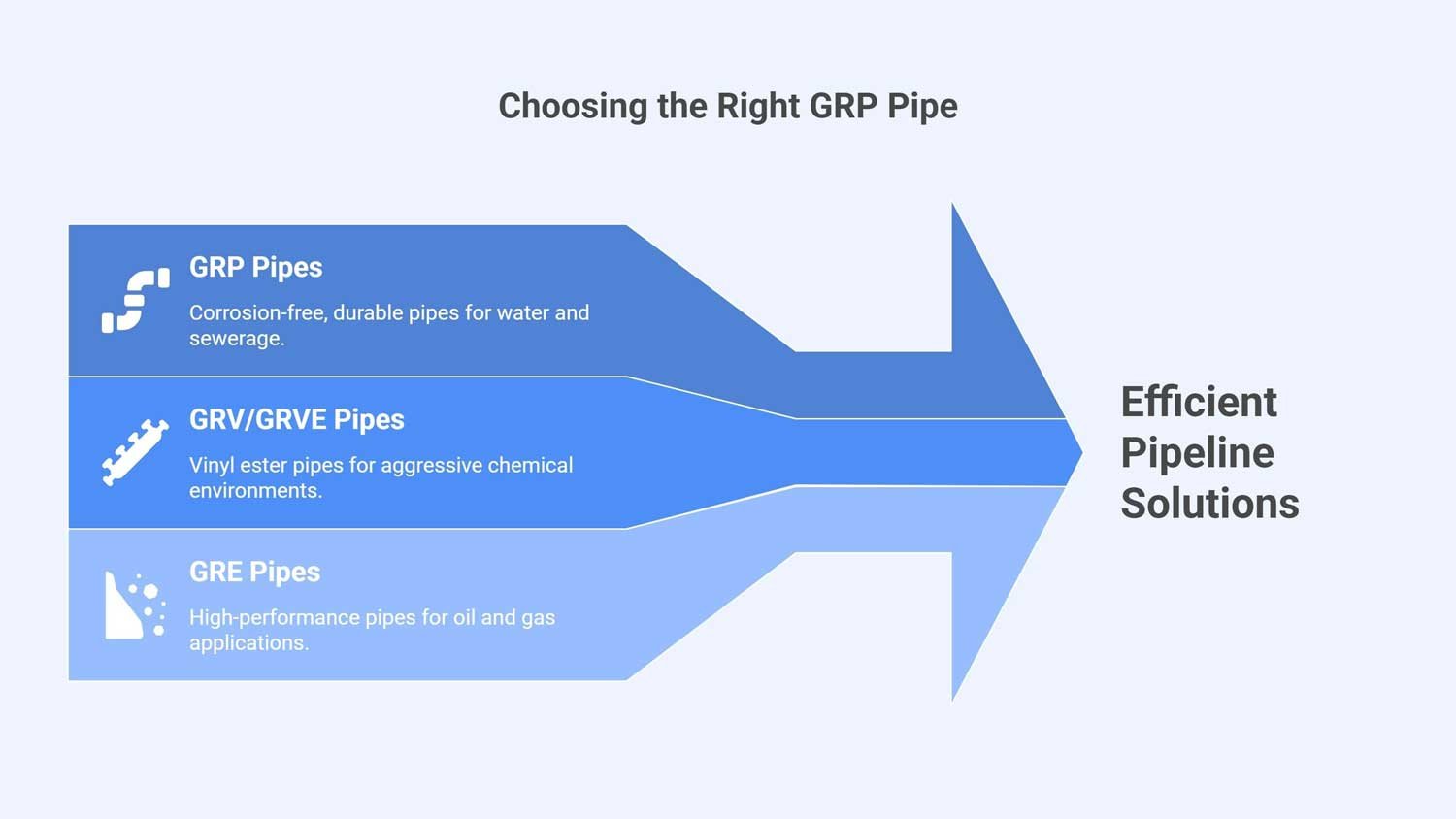

GRP Pipe Classification by Resin Type

GRP pipes are mainly made of a combination of glass fibers and resin matrix. Resin types contain polyester, vinyl ester, and epoxy, each of which acts perfectly in certain conditions.

- GRP (Glass Reinforced Plastic) Pipe: Polyester-based GRP pipes are used in general use cases that require moderate resistance to corrosion or chemicals. Water supply, sewer systems, and irrigation lines are the biggest share of GRP pipe usage.

- GRV/GRVE (Glass Reinforced Vinyl Ester) Pipe: vinyl ester GRP pipes show better performance against chemicals, acids, alkalis, and solvents, due to the resin linings. These pipes are mainly used for aggressive environments such as chemical processing or desalination plants.

- GRE (Glass Reinforced Epoxy) Pipe: Epoxy-based GRP pipes are superior in terms of resistance to chemicals, corrosion, and UV exposure. These pipes are popularly used in oil and gas and offshore applications.

GRP Pipe Material Compositions: Fiber, Resin, And Fillers

All GRP pipe types are made of two base components: glass fiber and resin matrix, and other additives to strengthen specific features in certain conditions.

Resin Systems Used in GRP Pipes

The resin matrices are added to the fibers or soaked into them to create a more resistant and improved structure in pipelines. Common resin types are unsaturated polyester, vinyl ester, and epoxy.

- Polyester: For general usage and cost-effective.

- Vinyl Ester: For chemicals and harsh conditions.

- Epoxy: For superior resistance and thermal stability, but it is costly.

Types of Glass Fiber Reinforcement

E-glass (alumino-borosilicate) or ECR-glass (electrical/chemical resistant) is the chosen option for GRP pipe, whether in axial, hoop, or helical orientation, designed to increase the pressure resistance.

What Are the Fillers and Additives in GRP Pipes? And how do They enhance the Final Performance?

There are multiple fillers that can be added to GRP pipes to eliminate specific problems. For instance, silica sand is used as a filler to increase the modulus of elasticity.

| Additive | Purpose | Common Applications | GRP Pipe Type |

|---|---|---|---|

| Fine Silica Sand | Increases wall stiffness, reduces cost | Water supply, sewerage, irrigation | GRP |

| Aggregate | Provides dimensional stability | Industrial pipelines, drainage systems | GRP |

| UV Stabilizers | Protects from sunlight degradation | Outdoor installations, marine applications | GRP, GRV |

| Flame Retardants | Reduces flammability, improves fire resistance | Above-ground piping, offshore platforms, process plants | GRP, GRE |

- Note: According to the ISO 14692, fillers should be balanced with resin and fibers to act effectively and reduce the probable failures.

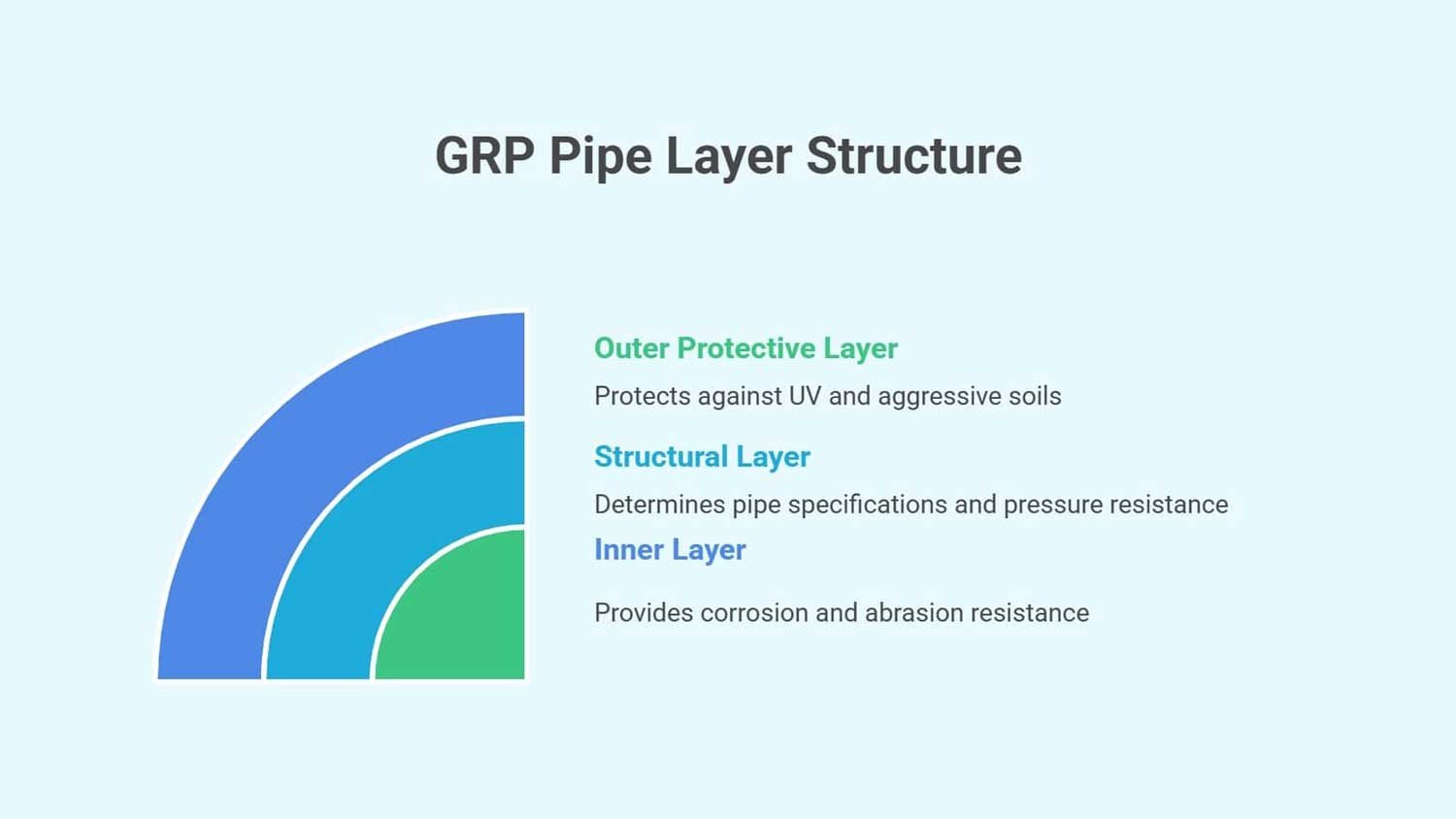

How Are GRP Pipes Layered and Structured?

The design of the GRP pipe’s layers includes three main layers: inner, structural, and outer layers. Let’s point out why to add each.

Inner Layer

The inner layer contains a layer rich in resin to make pipes resistant to corrosion and abrasion of fluids like acids, alkalis, and salts.

- Technical Fact: The Inner layer in GRP pipe creates a smooth inner surface that reduces the need for pumping energy. (Source: ScienceDirect)

Structural Layer

This layer is the main layer that adjusts central specifications of the GRP pipes like DN, PN, and SN by determining the pipe thickness to handle pressure (internal and external) and stress.

- Mechanical Point: The orientation of fibers can indicate how pipes resist pressure under heavy loads and hoop stress.

Outer Protective Layer

This layer is added normally in all GRP pipes to increase the resistance of the pipe under UV light or in aggressive soils. Unlike metal pipes that require a lot of protective cathodic layers, GRP pipes include this layer naturally.

GRP Pipe Types by Manufacturing Process

GRP pipes are manufactured by four main processes to shape pipelines for large-scale infrastructures or special designs in specific lengths.

Filament winding

Filament winding is the most common method to produce GRP pipes. This process starts with material preparation, and then the fibers go through twisting around a mandrel to shape. They provide pipes with features:

- High strength-to-weight ratio

- Best for large diameters and high-pressure systems

- Makes uniform fiber distribution

The role of CNC Machines: Scribd highlights that CNC machines can lead the way to accuracy in different sizes. They’re used to cut or shape the pipe’s ends.

Centrifugal Casting

In this process, the combination of fibers and resin goes through a rotating mold to shape the pipes with a smooth inner surface and protective coating. Point to consider:

- Smooth inner surface

- Used for medium-sized diameters

- Cost-effective for low to medium-pressure systems

Continuous Winding

This process uses a moving mandrel that winds both resin and fibers together to shape pipes with long lengths. This method is used when the site requires long pipes and fewer joints and fittings.

- Lesser joints, lesser probable leakage

- Large-scale and long-length installations

Hand/Spray Lay-Up

This process is known for two points: the requirement for professional workers and customized pipelines.

How does it work? This process goes through spraying the mixture of fibers and resin onto a mold to shape pipes in custom shapes or smaller lengths or diameter sizes.

- Lower cost for small batches or custom designs

- Less uniform, requiring more careful inspection

- Best for non-standard applications

GRP Pipe Classification by Performance

GRP pipes are made to handle specific pressure. This comes from the PN and SN rating of each pipe, which can be customized.

Pressure class (PN Ratings) shows the maximum pressure tolerance of pipes. It helps engineers to select the best pipe for their projects, as it can be costly if the wrong choice is made.

Stiffness Class (SN Ratings) indicates the pipe’s potential to resist under heavy external loads without deformation or cracking.

Points:

- Both SN and PN determine how thick the pipe will get

- The PN is expressed by bars and the SN by N/m2; check the table below for more information on GRP pipe specifications.

| Rating Type | Range | Common Use |

|---|---|---|

| Pressure Class (PN) | PN 1 – PN 32 | PN 10, PN 16 for standard use; PN 25, PN 32 for high pressure |

| Stiffness Class (SN) | SN 2500 – SN 10000 | SN 2500 – SN 5000 for medium duty; SN 10000 for heavy-functioning, deep burial |

GRP pipes can range in different SN and PN ratings, which affect wall thickness and final resistance under pressure.

Applications of Different GRP Pipe Types

GRP pipes include beneficial specifications to be chosen by engineers in various use cases, from deep-buried pipelines to cooling systems in energy sectors.

GRP Pipes

GRP pipes are such corrosion-free and durable pipelines that their initial costs may make buyers torn, but their lower overall cost makes them winners compared to metal pipes. These pipes include moderate resistance and are used in:

- Water supply

- Sewerage systems

- Municipal projects

GRV/GRVE Pipes

Vinyl ester-based GRP pipes perform better in aggressive conditions compared to standard GRP pipes. They’re used in:

- Chemical processing

- Desalination plants

- Industrial wastewater systems

These pipes can stand chemicals, acids, and salts with no corrosion or leakage for a decade with low maintenance requirements.

GRE pipes

GRE pipes are the best option for oil and gas piping systems where features such as resistance to pressure, temperature, and corrosion, besides the lightweight, make them easy-to-install pipes that need less repair compared to metal pipes.

Main use cases are:

- Oil & gas

- Offshore projects

These pipes are superior in each property of GRP pipe types. Choose GRE pipe for large-scale applications where contractors want to spend more money on higher performance.

What Are the Jointing and Fitting Methods of GRP Pipe Types?

GRP pipes are lightweight pipelines that ease the transportation process and installation by their diverse methods of connection. Check the fitting and jointing types of these pipes below:

GRP Pipe Fittings

GRP pipe fittings connect pipe ends with components like elbows, tees, bends, and flanges. These fittings can be made of the same material as GRP pipes or other materials to be aligned or to reduce the risk of leakage.

Jointing Methods of GRP Pipes

GRP pipe includes various jointing methods to be fitted into every site condition. These types can help engineers design pipelines easily while reducing the risk of leaks or cracks.

- Socket & spigot (Elastomeric Seal): To connect two pipes’ ends, a spigot one goes into another’s socket, and it is sealed to avoid leaks.

- Flanged Joint: This works with bolted flanges and a gasket to prevent leakage in high-pressure or aboveground pipelines.

- Laminated (Wrap-around) Joints: Once pipes are correctly fitted, the connection is made by resin and fiber wrapped around that area. (Source: Amiblu)

- Adhesive Bonded: Pipes or fittings are glued by adhesives or epoxy glue, then are stuck together. This method is used for low-pressure systems.

- Mechanical Couplings: Key-locks and sleeve couplings are such examples of this method, which are very reliable and permanent for sites that work for both restrained and unrestrained systems.

Installation Methods for GRP Pipes

GRP pipes with their resin-rich layer can be installed both above- and underground. The choice of each depends on application, environment, and pipe type.

1. Open Trench Installations

In this method, GRP pipes are placed in a dug trench and backfilled. They’re lightweight and need to be placed carefully to avoid cracks.

2. Trenchless technique for GRP Pipes

In trenchless installations like HDD or micro tunneling, pipes should be pushed through the ground with no excavation included. In high-pressure systems, it does not matter to adjust the PN and SN ratings.

3. The Aboveground Installations: The Case of Marine Systems

GRP pipes are used in marine conditions where they require additives to be UV resistant in outdoor applications. Extra coatings and gel coats can also effectively reduce the risk of abrasion in under-the-sun use cases.

- UV Protection: Important for outdoor pipes to stop damage from sunlight.

- Corrosion Protection: Needed for pipes in marine areas to prevent saltwater damage.

- Support Systems: Pipes must be adequately supported to avoid sagging.

International Standards and Compliance for GRP Pipes

GRP pipes follow global standards and guidelines to be aligned for various industrial use cases all around the world. Here are the most-used ones:

- ISO 14692 for oil and gas (covers materials, design, installation)

- ASTM D3517 for fiberglass pipes

- AWWA C950 for water systems

- EN/BS standards for engineering and construction

- SHELL DEP for offshore use

Also, there are some regional standards, like IS codes for India, for material selection, design, installation, and maintenance considerations.

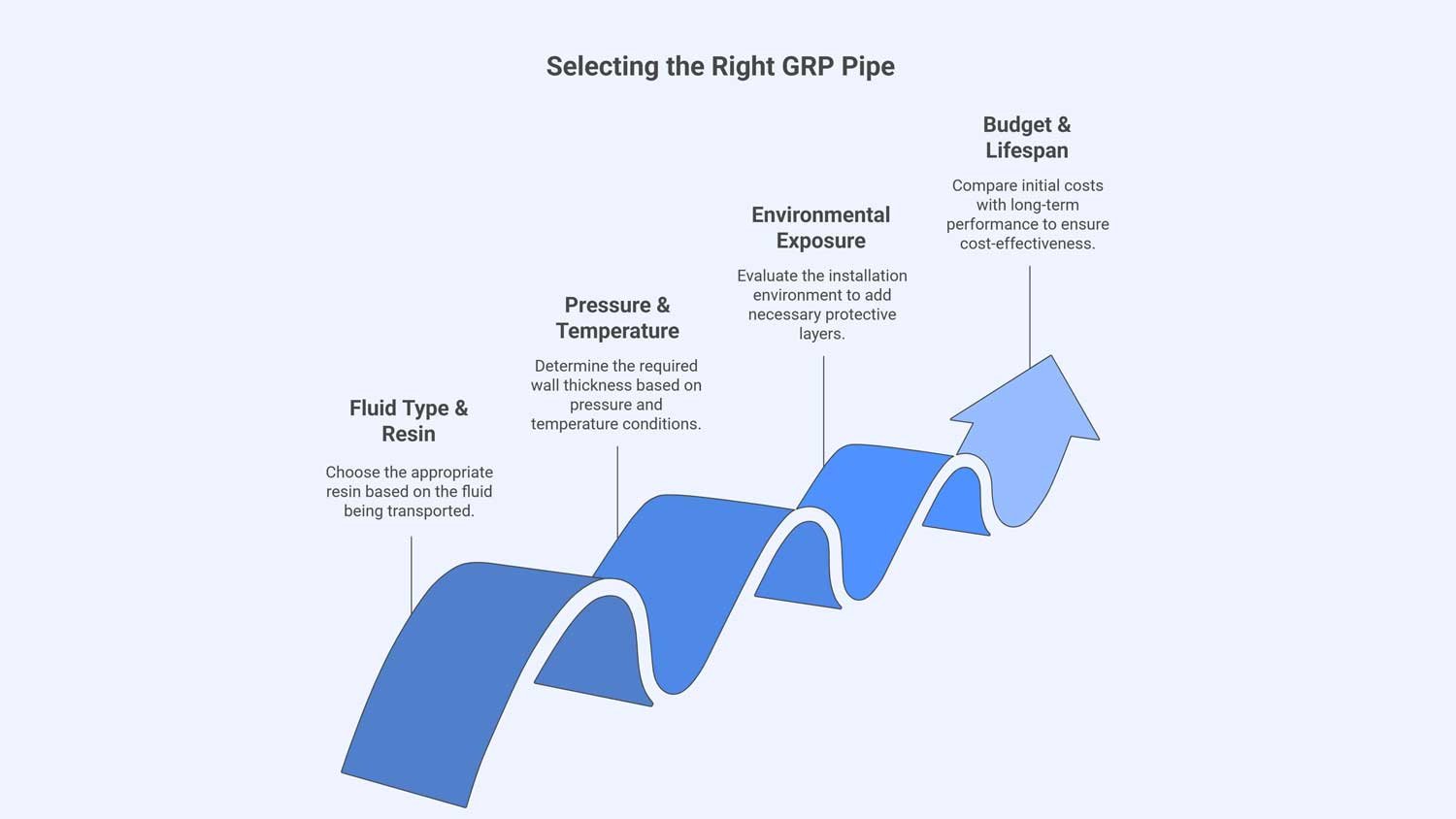

How to Select the Right GRP Pipe for Your Project? A Step-By-Step Guide

To select the most proper pipeline for your project, follow the steps below to reach the most reliable one, while preventing costly mistakes.

First: fluid type and the resin choice

Choose the right resin type (polyester, vinyl ester, or epoxy) based on what’s going to be transformed. It shows how pipes should react to resist corrosion, abrasion, or chemical exposure after a long time of installation.

Second: Pressure and Temperature Conditions

Check tables and charts for PN and SN ratings to choose the right wall thickness that can withstand specific internal and external pressures.

Third: Environmental Exposure

Evaluate the place for the installation type (aboveground, underground, or in marine conditions) to add any protective layers for UV exposure or salt-resistance.

Last: Budget and Lifespan Considerations

Compare the initial costs and overall costs in long-term performance under harsh conditions. GRP pipes usually include such higher initial costs compared to their alternative, but they last over 50 years with the least maintenance needs.

Final Wrap-Up

GRP pipes are one of the top choices in modern piping systems due to their lightweight, corrosion resistance, and cost-effectiveness. GRP, GRE, and GRV are three central types of GRP that each can be used in specific situations. GRE is used for oil and gas, GRV for chemical plants, and GRP for general use cases like water supply. The proper selection will prevent costly mistakes for decades.

FAQs

1- What are GRP pipes made of?

GRP pipes are made of resin reinforced with glass fibers.

2- What are the advantages of GRP pipes?

They are lightweight, corrosion-resistant, and durable.

3- How do you join GRP pipes?

GRP pipes are joined with spigot and socket, flanged, or laminated joints.

about

The Author

Farshid Tavakoli is a seasoned professional in engineering and international trade. Holding degrees in Electrical Engineering, Mechatronics, and a Doctorate in Business Administration (DBA) from the University of Lyon, he also has a strong background in industrial automation and production line technologies.

For over 17 years, he has led an international trading company, gaining deep expertise in commercial solutions tailored to industrial needs. With more than 8 years of active involvement in infrastructure development, he specializes in the supply of electromechanical equipment for water and wastewater treatment plants and transfer projects.

Together with comapny expert team, he now provides consultancy and integrated solutions for sourcing and implementing complex infrastructure projects across the region.