When selecting the right pipe for your piping systems, you may face DN, PN, or SN, but what exactly do they refer to? The nominal diameter (DN) refers to the pipe’s internal size, which indicates the flow rate. GRP pipes are the top choice for piping projects due to their high resistance to corrosion, heavy loads, and their durability over decades.

In this article, we’re showing you how each of the GRP pipe size specifications impacts the final choice. Check the table below before diving into the following sections.

| Topic | Key Points | Details | Size Range | Applications |

|---|---|---|---|---|

| GRP Pipe Sizes (DN) | Defines internal diameter | Affects flow and pipe selection. | DN 50–4200+ mm | Residential, industrial, infrastructure |

| Pressure Classes (PN) | Internal pressure resistance | Determines wall thickness based on pressure. | PN 1–40 | Water mains, pressurized systems |

| Stiffness Classes (SN) | Resistance to external loads | Measures deformation resistance under external load. | SN 2500–10000+ | Deep burial, trenchless systems |

| Wall Thickness | Depends on PN and SN | Increases with higher PN and SN for strength. | Varies by DN, PN, SN | All applications |

| Pipe Length | Available in standard and custom lengths | 6m and 12m standard; custom for large diameters. | 6m, 12m, Custom | Infrastructure, trenchless installs |

| Material Advantages | Lightweight, corrosion-resistant, durable | Resists corrosion, UV, and chemicals for longevity. | N/A | Chemical, wastewater, marine systems |

What Are the Standard GRP Pipe Diameter Ranges?

GRP pipes are designed in a wide range of diameter sizes to control the flow rate in various use cases, from rural water transmission to high-pressure chemical plants. Here are three central DN ranges:

- Small Pipes (DN 50-300 mm) are made to be used in residential water systems or smaller industrial applications.

- Medium Pipes (DN 300-1000 mm) that are mainly used for municipal water distributions or some sort of sewer systems.

- Large Pipes (DN 1000-4200+ mm) are customized for the main infrastructures in irrigation networks, large-scale sewerage systems, and chemical processing.

Engineering Point: Choose the right size based on your actual demands. Wrong selection results in a waste of pumping energy usage or cracks under high-pressure flows.

What Are the Pressure Classes of GRP? And How Do They Affect Pipe Size?

Pressure class shows how each pipe can resist internal pressure, which affects the wall thickness. The higher the PN, the thicker the walls are.

Norm of PN Classes

PN ranges from PN 1 to PN 40, each of which can handle a certain amount of pressure. In high-pressure flows, higher PNs are recommended.

How Pressure Class Influences Wall Thickness

The higher the PN gets, the thicker the GRP pipe needs to be to resist that pressure, which can cause failure if chosen wrongly.

How to Match Size and PN Correctly?

Consider a pipe with a DN 600 and PN 6 compared to a pipe with the same DN and PN 25, which includes thinner walls and is perfect for small-scale piping systems with lower flow rates.

What Is the Stiffness Class (SN) of GRP Pipes? And How Does It Change the Pipe Design?

As PN refers to the ability of a pipe to resist internal pressures, SN shows how pipes can handle external loads without deformation.

What Are the Main Ranges of SN Classes?

SN comes in a range of 2500 to 20000 or more. High SN classes can reach up to 1,000,000, which are used for deep burial or trenchless installations where pipes should resist certain pressures.

How are SN and Pipe Diameter related?

To control the probable cracks and damage under high-pressure external loads, the stiffness class increases as DN goes up.

Is the Burial Depth Effective in the Choice of SN Class of GRP Pipes?

As the pipeline goes deeper, it’s necessary to choose high SN classes. For instance, in deep burial installations, a 1000 DN pipe needs a 10,000 SN or more to act perfectly under such loads in a long-term performance. (Source: Flowtite)

What Is the GRP Pipe Outer Diameter (OD)?

The outer diameter (OD) is the external size of each pipe that represents how joints and fittings are set across all PNs. This matter shows how influential it might be for further installation and performance under heavy loads.

The Tolerance by the DN Ranges

A short but necessary tolerance in each pipe is considered to act better when fitting and jointing are performed. For instance, a DN 300 pipe usually has a tolerance of ±1.0 mm.

How Essential Is Pipe Size and Joint Method Choice?

The right measurement of OD does matter when joints are applied for a reliable alignment with no leakage or misconnection in further installations.

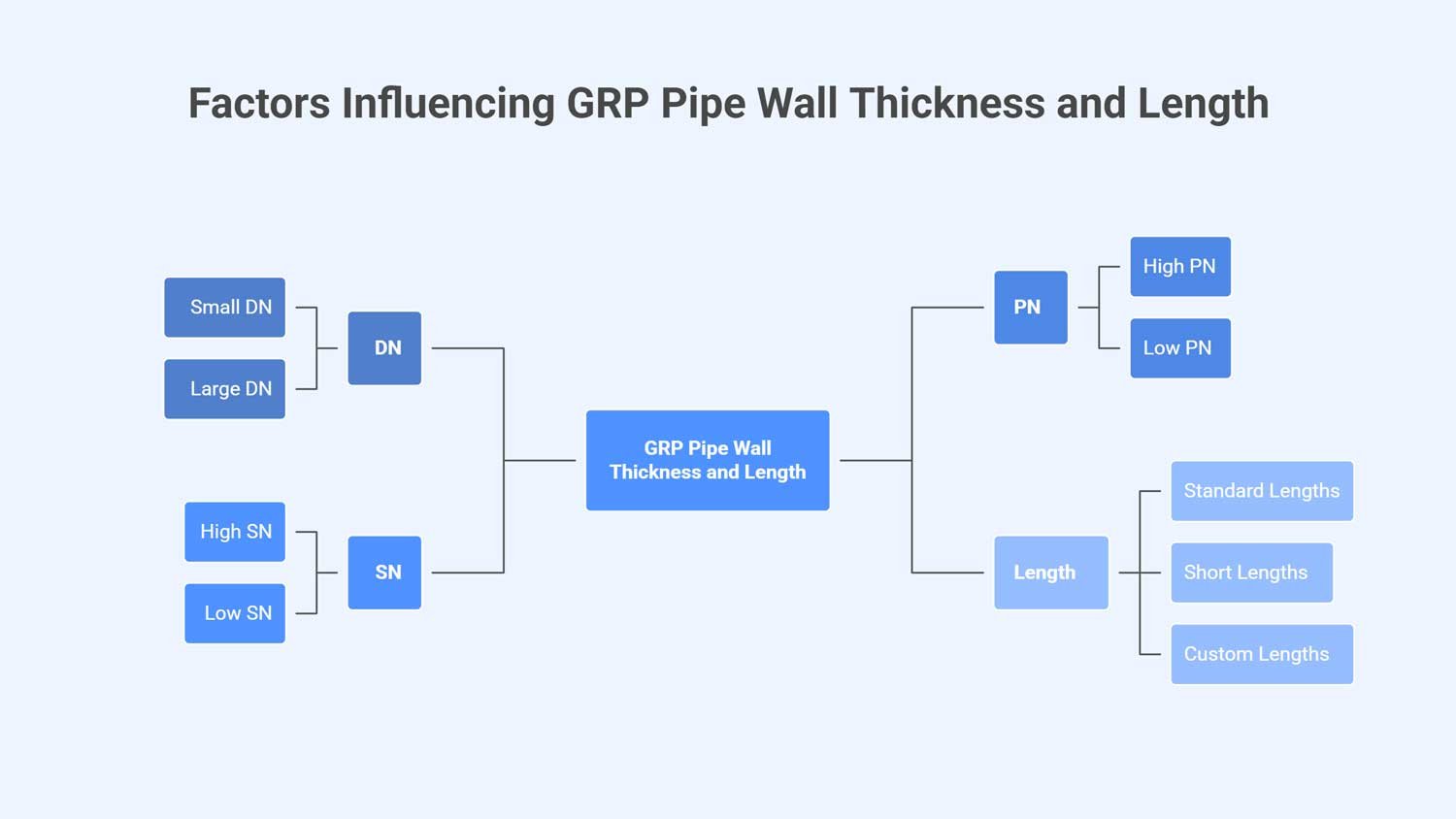

How DN, PN, And SN Indicate the Final Wall Thickness Value?

To determine the wall thickness of each pipe, there are some influential factors such as DN, PN, and SN. For instance, a pipe with a high DN range and high values of SN and PN is likely to come in thicker walls to handle such pressure in heavy traffic.

What Happens to The Pipe Structure? The Case of Large and Small DN

In small DNs, the walls are thinner, though they must follow specific standards to avoid cracks or deformation under stress. While large DN pipes are thicker in walls and can withstand pressure whether internally or externally. (Source: Amiblu)

What Sizes and lengths of GRP Pipe are Available?

GRP pipes are available in various lengths, while they’re made to custom changes for installation, transportation, and storage.

- Standard Lengths: GRP pipes are mainly made by following global standards that shape them into lengths of 6 to 12 meters. They’re used in most applications with easy installation and transportation.

- Short Lengths: In specific use cases like pipe jacking or trenchless installation, where pipes should be easy to handle in hard-to-access sites, 1-6 meter lengths can ease the process.

- Custom Lengths: When the DN range gets high, pipes can be manufactured in lengths up to 15 meters. This matter can decrease the need for joints and ease the installation in large-scale infrastructure use cases.

GRP Pipe Sizing Tables and Charts

Once you have an understanding of the essential specifications of GRP pipe that influence the pipe size, it’s time to inspect them through tables to choose the most reliable pipeline aligned with your project demands.

| GRP Pipe Diameter (DN)(mm) | GRP Pipe Outer Diameter OD (mm) | Tolerance +/- (mm) |

|---|---|---|

| 200 | 207 | +1.0 / -1.0 |

| 300 | 310 | +1.0 / -1.0 |

| 350 | 361 | +1.0 / -1.2 |

| 400 | 412 | +1.0 / -1.4 |

| 450 | 463 | +1.0 / -1.6 |

| 500 | 514 | +1.0 / -1.8 |

| 600 | 616 | +1.0 / -2.0 |

| 700 | 718 | +1.0 / -2.2 |

| 800 | 820 | +1.0 / -2.4 |

| 900 | 924 | +1.0 / -2.6 |

| 1000 | 1026 | +2.0 / -2.6 |

| 1100 | 1128 | +2.0 / -2.6 |

| 1200 | 1229 | +2.0 / -2.6 |

| 1300 | 1330 | +2.0 / -2.6 |

- Technical Insight: Scribd highlights that these tolerances can aid engineers in reaching the connections in pipe ends with the least leakage and probability of cracks or deformations.

| DN (mm) | PN 6 / SN 5000 | PN 10 / SN 5000 | PN 10 / SN 10000 | PN 16 / SN 5000 | PN 16 / SN 10000 |

|---|---|---|---|---|---|

| 300 | 5 mm | 6 mm | 6 mm | 6 mm | 6 mm |

| 350 | 6 mm | 7 mm | 7 mm | 7 mm | 7 mm |

| 400 | 7 mm | 8 mm | 8 mm | 8 mm | 8 mm |

| 450 | 7 mm | 9 mm | 9 mm | 9 mm | 9 mm |

| 500 | 8 mm | 10 mm | 10 mm | 10 mm | 10 mm |

| 600 | 10 mm | 12 mm | 12 mm | 12 mm | 12 mm |

| 700 | 11 mm | 14 mm | 14 mm | 14 mm | 14 mm |

| 800 | 12 mm | 15 mm | 15 mm | 15 mm | 15 mm |

| 900 | 14 mm | 17 mm | 17 mm | 17 mm | 17 mm |

| 1000 | 15 mm | 19 mm | 19 mm | 19 mm | 19 mm |

| 1100 | 17 mm | 21 mm | 21 mm | 21 mm | 21 mm |

| 1200 | 18 mm | 23 mm | 23 mm | 23 mm | 23 mm |

| 1300 | 20 mm | 25 mm | 25 mm | 25 mm | 25 mm |

| 1400 | 21 mm | 27 mm | 27 mm | 27 mm | 27 mm |

| 1500 | 23 mm | 28 mm | 28 mm | 28 mm | 28 mm |

| 1600 | 24 mm | 30 mm | 30 mm | 30 mm | 30 mm |

| 1700 | 26 mm | 32 mm | 32 mm | 32 mm | 32 mm |

| 1800 | 27 mm | 34 mm | 34 mm | 34 mm | 34 mm |

| 1900 | 29 mm | 36 mm | 36 mm | 36 mm | 36 mm |

| 2000 | 30 mm | 38 mm | 38 mm | 38 mm | 38 mm |

| 2100 | 32 mm | 39 mm | 39 mm | 39 mm | 39 mm |

| 2200 | 33 mm | 41 mm | 41 mm | 41 mm | 41 mm |

| 2300 | 34 mm | 43 mm | 43 mm | 43 mm | 43 mm |

| 2400 | 36 mm | 45 mm | 45 mm | 45 mm | 45 mm |

| 2500 | 37 mm | 47 mm | 47 mm | 47 mm | 47 mm |

| 2600 | 39 mm | 49 mm | 49 mm | 49 mm | 49 mm |

| 2700 | 40 mm | 50 mm | 50 mm | 50 mm | 50 mm |

| 2800 | 42 mm | 52 mm | 52 mm | 52 mm | 52 mm |

| 2900 | 43 mm | 54 mm | 54 mm | 54 mm | 54 mm |

| 3000 | 45 mm | 56 mm | 56 mm | 56 mm | 56 mm |

| 3100 | 46 mm | 58 mm | 58 mm | 58 mm | 58 mm |

| 3200 | 48 mm | 60 mm | 60 mm | 60 mm | 60 mm |

| 3300 | 49 mm | 61 mm | 61 mm | 61 mm | 61 mm |

| 3400 | 51 mm | 63 mm | 63 mm | 63 mm | 63 mm |

| 3500 | 52 mm | 64 mm | 64 mm | 64 mm | 64 mm |

| 3600 | 53 mm | 65 mm | 65 mm | 65 mm | 65 mm |

| 3700 | 55 mm | 67 mm | 67 mm | 67 mm | 67 mm |

| 3800 | 56 mm | 68 mm | 68 mm | 68 mm | 68 mm |

| 3900 | 58 mm | 70 mm | 70 mm | 70 mm | 70 mm |

| 4000 | 59 mm | 71 mm | 71 mm | 71 mm | 71 mm |

- Standardish Tip: ISO 10639 shows how GRP pipe should be designed, whether by DN, PN, SN, or the wall thickness coming from all previous aspects.

Last Station: The Right GRP Pipe Selection Size for Your Project

After inspecting each aspect of GRP pipes, it’s time to choose the one most relevant to your project requirements. But where to start? Below, we provide you with a step-by-step selection guideline.

Step 1: Indicate flow rate → Select DN

First, calculate the desired flow rate of the piping system. Choose larger DNs for higher flow capacity, and remember that an inappropriate selection can result in additional costs.

Step 2: measure the pressure rate → Select PN

Evaluate the internal pressure value to make specific changes in wall thickness. (Higher PN requires thicker walls to withstand internal pressures.)

Step 3: check site’s burial or loads → Select SN

Once you’ve checked the internal pressure and indications of the PN and wall thickness, it’s time to assess the predicted burial depth of the pipes. The deeper you bury pipes, the higher SN you should select.

- Real-World Example: For a water distribution system with moderate pressure and normal burial depth, select a DN 600, PN 10, SN 5000 to resist both internal and external pressure for a long-lasting performance.

Expert GRP Pipe Sizing Support from PipeLineCoreGroup

Do you want to find the perfect GRP pipe for your next project? Line Core Pipe Group has high-quality engineering-grade GRP pipes in all sizes, from DN 50 to DN 4000+, and both standard and custom SN and PN classes to meet your needs.

You can count on us to deliver the right solutions for your projects, with complete sizing charts, technical support documents, and fast delivery.

Get in touch with the PipeLineCoreGroup consultants or access our full GRP sizing specifications. Visit our website now and start designing your pipeline today!

Final Thoughts

To achieve a safe, long-lasting piping system, selecting the proper GRP pipe is the first step. Check industry standards and specifications to ensure consistency throughout the process. It’s recommended that engineers make a checklist that includes evaluation of required pressures for the proper DN, PN, and SN in pipeline selections.

FAQs

1- How do I choose the right DN size?

Check the flow rate of your system. Higher DN pipes are typically used for large-scale projects with higher flow capacities.

2- Can I get custom GRP pipe sizes?

Yes, manufacturers can design custom PN and SN values, as well as custom pipe lengths, based on your project needs.

3- What is GRP pipe sizing?

It’s selecting the correct DN, PN, and SN for your system’s flow, pressure, and load needs.

about

The Author

Farshid Tavakoli is a seasoned professional in engineering and international trade. Holding degrees in Electrical Engineering, Mechatronics, and a Doctorate in Business Administration (DBA) from the University of Lyon, he also has a strong background in industrial automation and production line technologies.

For over 17 years, he has led an international trading company, gaining deep expertise in commercial solutions tailored to industrial needs. With more than 8 years of active involvement in infrastructure development, he specializes in the supply of electromechanical equipment for water and wastewater treatment plants and transfer projects.

Together with comapny expert team, he now provides consultancy and integrated solutions for sourcing and implementing complex infrastructure projects across the region.