GRE pipes are known as the most resistant pipes among the FRP pipe family due to their superior GRE pipe specifications. Therefore, GRE pipes are a modern solution for oil and gas, water, utilities, and industrial services. The manufacturers suggest GRE pipes to EPC contractors, owners, and engineers due to the final goods’ quality verified by testing and QC units.

This post guides you to the GRE pipe specifications, standards, design basis, dimensional criteria, and other properties that can customize the choice of GRE materials for your piping systems.

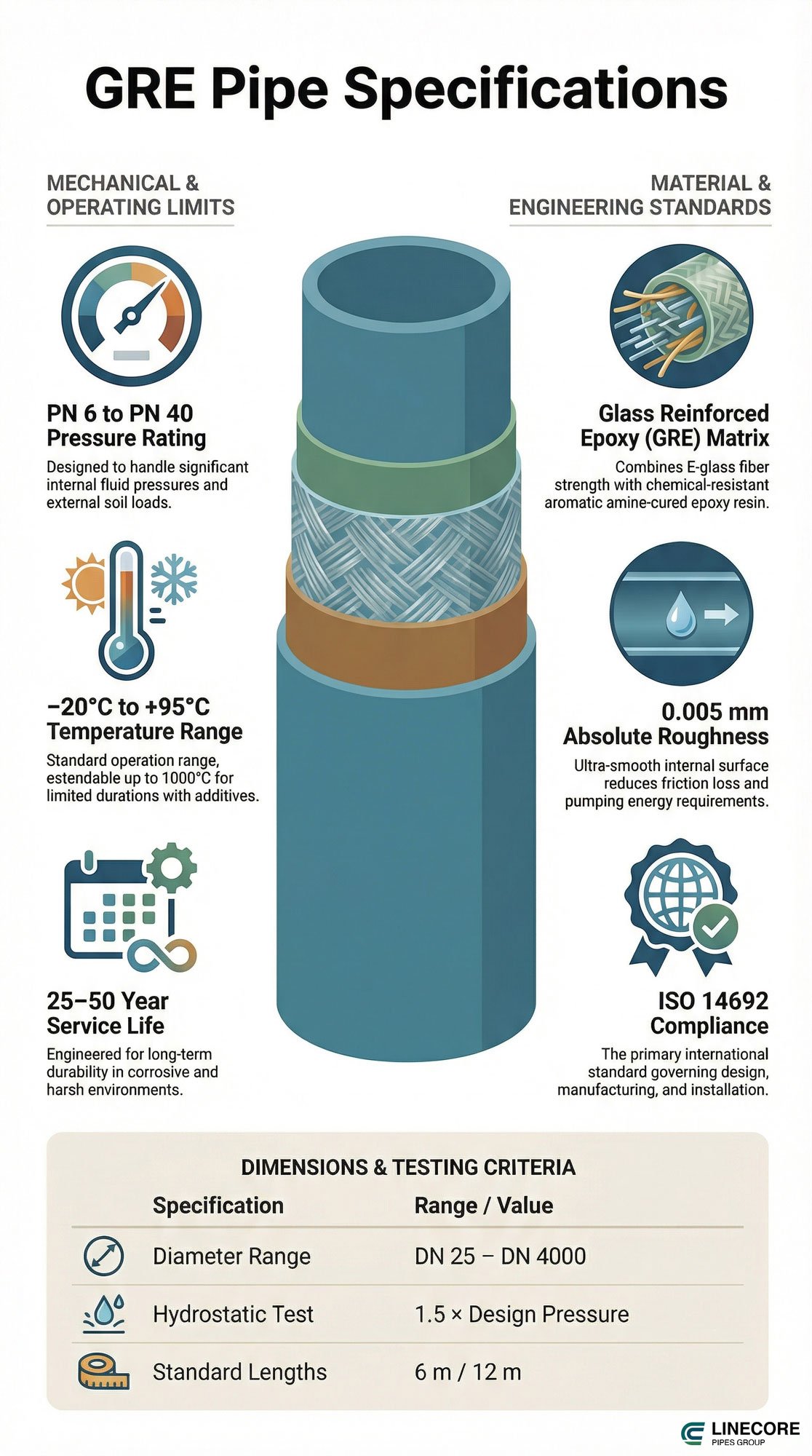

Before going through the blog post, let’s check the guidance below that shows the GRE pipe specifications in short but comprehensive form!

| Category | Specification | Typical Value / Range |

|---|---|---|

| Pipe type | Glass Reinforced Epoxy (GRE) | Thermoset composite |

| Applicable standard | ISO 14692 | Latest edition |

| Design life | Service life | 25–50 years |

| Diameter range | Nominal diameter | DN 25 – DN 4000 |

| Pipe length | Standard length | 6 m / 12 m |

| Resin system | Epoxy resin | Chemical & heat resistant |

| Reinforcement | Glass fiber | E-glass / ECR |

| Manufacturing | Process | Filament winding |

| Pressure class | PN rating | PN 6 – PN 40 |

| Design factor | Long-term safety factor | ≥ 1.25 |

| Operating temperature | Continuous service | −20°C to +95°C |

| Stiffness class | Ring stiffness (SN) | 2500 / 5000 / 10000 N/m² |

| Wall thickness | Design basis | Strain-based (ISO 14692) |

| Internal roughness | Absolute roughness | ≈ 0.005 mm |

| Joint types | Permitted joints | Adhesive, rubber seal, laminate |

| Angular deflection | Per joint | Up to 1–3° |

| Fittings & flanges | Pressure rating | Equal to pipe PN |

| Installation | Application | Above & below ground |

| Hydrostatic test | Test pressure | 1.5 × design pressure |

| Inspection | Visual & dimensional | 100% |

| Documentation | Deliverables | Design, test, as-built |

GRE Pipes: Definitions, Terminology, and Abbreviations

First, let’s get into the GRE pipes. What exactly do they mean by G.R.E? This interpretation aids the audience to perceive the design, procurement, manufacturing, and construction levels just by the meaning of the GRE pipes.

Definition of GRE Pipe

GRE refers to Glass Reinforced Epoxy, which uses glass fibers to add strength and a resin matrix (Epoxy type) for resistance to temperature and pressure under heavy loads or corrosive conditions.

- Glass fibers: To add tolerance to internal, external pressure, or physical damage.

- Epoxy Resin: Used to make pipes away from chemical or thermal exposure by inner and outer layers.

Composite Piping Terminology: What We Discuss in the Next Sections

These terms include a wide range of pipe specifications where GRE pipes can be a changeable option for various piping cases.

- Hydrostatic Design Basis (HDB)

- Pressure class (PN)

- Stiffness class (SN)

- Corrosion barrier

- Structural laminate

- Allowable strain

- Design life

How Do GRE Pipes Differ from Other Composite Pipes?

Compared to unsaturated polyester or vinyl ester in GRP and GRV pipes, GRE with epoxy resin type resists higher temperatures and manufacturers mainly add some additives that increase this temperature up to a thousand degrees for a limited time, while other types may fail.

Applicable Standards, Codes, and Design Basis

GRE pipes require global standards and design codes to achieve that reliability in every use case, all around the world. This section defines some of the most-used ones, like ISO 14692.

In the international view, GRE piping systems follow ISO 14692 for oil and gas pipelines in the case of pressure design, joint testing, manufacturing monitoring, and installation requirements.

| Standard | Purpose / Application | Ranges |

|---|---|---|

| ISO 14692 | Design, manufacture, installation | DN 25–4000, PN 6–40 |

| ASTM D2992 | Hydrostatic design basis | 10,000 hours test |

| ASTM D695 | Compressive strength | >200 MPa |

| ISO 10928 | Stiffness | SN 2500, 5000, 10000 N/m² |

| AWWA C950 | Water utilities | 150–300 psi |

| EN 1796 | Water supply pipes | DN 80–1200 |

| NORSOK M-710 | Offshore pipes | −20°C to +60°C |

| DNV RP-F109 | Offshore pipes | 25–50 years design life |

These standards help both manufacturers and engineers to approve their design and final set for long-term performance during the 50-year lifespan of GRE pipes.

Design Conditions and Service Requirements

There are some factors that affect the design and operations of the GRE pipelines. Each indicates how pipes behave under certain conditions.

- Pressure Rating: GRE pipes can handle pressure from PN 6 to PN 40; this strength can be changed by design and wall thickness.

- Temperature Tolerance: A typical range between −20°C and +95°C; if additives are added to the material mix, the tolerance goes up to a thousand degrees. (Source: ResearchGate)

- External Pressure Conditions: GRE pipes can endure vacuum and external loads like soil in underground installations.

- Corrosion Resistance: Composite pipes are chosen based on their resistance level in various piping cases. At the same time, GRE pipes can be used for corrosive lines due to their perfect resistance to corrosion.

- Installation Environment: In aboveground installations, GRE pipes require such epoxy coatings for UV exposure and physical damage.

Requirements for Materials and Manufacturing

When you build GRE pipes, you have to choose materials that will last for decades without corroding or breaking under pressure.

1. Glass Fiber Reinforcement

We use E-glass fibers as continuous rovings with filaments that are 6 to 24 microns thick and have a tensile strength of over 2,400 MPa. They make up 60% of the weight, which makes the hoop and axial strength stronger.

2. Epoxy Resin System

According to ScienceDirect, it takes 20 to 40 minutes for aromatic amine-cured epoxy to gel and 130 to 160 degrees Celsius to cure. It has a viscosity of 500 to 1,000 cP, which makes it good for impregnation. It can withstand heat and chemicals up to 95 degrees Celsius.

3. Linings for Corrosion Resistance

The 0.5-1 mm inner liner is made of C-glass or resin-rich layers that keep acids and hydrocarbons from getting through.

4. Structural Lamination

The core is made by winding it in a helical shape at an angle of 55 to 60 degrees. It was designed through regression testing with strains below 0.9% for pressure handling.

5. UV Protection

Gelcoat or polyurethane covers the outside to protect it from UV rays and wear and tear in setups that are open to the elements.

6. Standards for Manufacturing Process

Filament winding on mandrels with controlled tension, along with post-curing, makes sure that everything is the same and meets ISO 14692-2.

Pipe Classification and Design Criteria

To design your pipeline correctly, it’s required to figure out the right GRE pipe classes, like PN and SN ratings.

● Pressure Class (PN)

PN is for when the pipe must handle internal pressure of high-pressure fluid flows, which is measured in bars. They usually announce this matter with PN6, PN10, or PN16. The more PN gets, the better the pipe can handle inner pressures.

● Stiffness Class (SN)

As noted in Scribd, SN indicates how pipes can tolerate deformation under the external forces, measured in newtons per square meter, like SN2500, SN5000, SN10000. It’s selected by the burial depth or soil conditions (soft or rocky).

● How Pipes Are Kept Safe for a Long-Lasting Lifespan?

These pipes are checked by hydrostatic tests (about 1.8 basic values) to last over 50 years, which is also verified by ASTM D2992 for long-term performance under heavy loads.

Dimensional Requirements and Tolerances

GRE pipes are manufactured to handle specific conditions like marine conditions in oil and gas pipelines. A kind of size, like diameter, ranges from DN 25 to DN 4000, from small- to large-scale manufacturing sizes.

| Item | Typical Requirement |

|---|---|

| Diameter range | DN 25 – DN 4000 |

| Standard length | 6 m / 12 m |

| Ovality | ≤ 1–2% of OD |

| Straightness | ≤ 0.5% of length |

| Weight tolerance | ±5% to ±10% |

Standard pipe lengths are 6 m and 12 m, while the wall thickness relies on PN and SN, all mainly defined by ISO 14692.

Long-Term Performance, Temperature, and Pressure

To avoid failures in real life, it’s important to know how GRE pipes work under pressure and heat over time.

Pressure, Regression Plots, and Safety Factors for GRE Pipes

At first, GRE pipes stretch when they are under pressure until they leak or break. Creep causes things to slowly get weaker over time when they are under constant stress.

Creep rupture is when stress causes cracks to form over time. Regression plots show the relationship between log stress and log time to figure out how long something will last.

To make up for the epoxy softening, lower the pressure rating by about 1% for every degree above 65°C.

Use 1.8 safety factors to keep pressures below PN, temperatures below 95°C with derating, and strains below 0.9%.

Hydrostatic Design Basis (HDB)

HDB uses accelerated tests to predict strength over 50 years and aims for 0.65% strain for safety in GRE.

Mechanical, Structural, and Hydraulic Properties

In this section, we represent the mechanical and structural properties of GRE pipes, such as axial stress performance, tensile hoop, resistance to collapse and internal corrosion, and friction loss.

- Pipe stiffness: Pipes are resistant to external loads from deformation or degradation due to layers of epoxy resin, which adds both strength and resistance to chemicals.

- Hoop and Axial Stress: GRE pipes are designed to resist both hoop and axial forces and pressure or temperature changes from the outer sources.

- Compressive Properties: GRE pipes are made of glass fibers in many directions to add to their strength to resist the internal pressure of fluids and the external pressure of rocky soils. (BHEL)

- Internal Surface: GRE pipes include such a smooth inner surface made via centrifugal casting to resist corrosion, reduce the need for extra pumping energy, and minimize friction loss during their lifetime.

Jointing Methods of GRE Pipes

GRE pipes are connected together via various methods to be matched and flexible in all locations and use cases, from deep burials to oceans. Here are the most-used methods:

- adhesive-bonded bell-and-spigot joints with epoxy adhesives

- mechanical ones like O-ring sealed couplings

- Flanged Joints or Laminated Joints

These joints are verified by standards like ISO 14692 for oil and gas piping systems for both long-term and short-term performances to check if there’s a flaw in their properties, such as thermal stability, caused by improper jointing.

Gaskets, Bolting, and Torque Requirements

Use EPDM or Viton gaskets to seal the bolts, which should be grade 8.8 or above and torqued according to ASME PCC-1 rules, which recommend using 50–100 Nm depending on the size to keep the flange from crushing.

GRE and Metallic Flange Interfaces

To connect GRE pipes to metallic pipes like steel pipes, fittings are the same as those for GRE to keep the whole pipeline from leakage. Also, in some probable cases, some welding may have found.

Transportation, Handling, and Installation of GRE Piping Systems

Once pipes are connected together, it’s time to bring them to the final station: the operating site. Dents are used for handling pipes at low heights (less than 2 meters) with no UV light included.

Above-Ground and Underground Installations

GRE pipes are used for both above-ground and underground pipelines, which require such jointing methods and outer layer preparation to resist both heavy loads and UV exposure.

Soil Loads and Restraint

- Use Marston’s formula to figure out how much dirt will be on top of underground pipes.

- To handle pressure surges, use push blocks at bends.

- To keep pipes from shifting due to thermal shifts, anchor them at regular intervals.

Stress Analysis Requirements

Once pipes are installed, they must pass some tests and analysis to ensure their long-term performance in hard-to-access sites and harsh conditions.

- The tool CAESAR II helps to check pipe resistance in earthquake events and axial, hoop, or bending stresses.

Inspection, Testing, and Technical Documentation

At the last station, we’ve got the inspection, testing, and documentation for further tracking. Below, we provide you with a table you can pass through each step. Once you get to the end, your piping system will be completely checked.

| Step/Item | Description/Method | Tolerance/Criteria | Example Result |

|---|---|---|---|

| Manufacturer Qualification Check | Review certifications, personnel training, quality docs. | ISO 9001 compliant; Annex C training min 40 hours. | Cert valid, 5 qualified fitters. |

| Raw Material Inspection | Visual/cert review for fibers, resin, adhesives. | Viscosity 500-1000 cP; no damage. | Viscosity 750 cP, certs match. |

| Visual Inspection (Factory) | Check for voids, cracks on surfaces. | Voids <1.5mm deep; no cracks. | Minor voids repaired. |

| Dimensional Verification | Measure thickness, diameter, length. | Thickness ±10%; ovality <1% DN. | Thickness 5.2mm (target 5mm). |

| Barcol Hardness Test | ASTM D2583 on laminates; avg 10 readings. | 35-40 units; ≥90% min. | Avg 38 units. |

| Factory Hydrostatic Test | Pressurize 1.5x design for 1 hour. | No drop >5%; no leaks. | Held 30 bar, no drop. |

| Field Hydrostatic Test | Pressurize 1.5x operating for 1-24 hours. | Drop <5% (temp-adjusted); no leaks. | Held 15 bar, 1% drop. |

| Final Documentation Review | Compile certs, reports, drawings. | Complete records for 50-year life. | Full package submitted. |

Also, we fill the results section with the expected values or finish with a sense of what you’ll face after testing is done.

LineCore Pipes Group: GRE Piping Engineering Partner

At LineCore Pipes Group, we not only supply GRE piping system materials but also provide a wide range of customized pipes for moderate or harsh environments. GRP. GRE and GRV pipes, plus their fittings and jointing pieces, are manufactured to the highest standards, ready for installation in your projects. Our consultants also recommend an expertized solution, specifically designed, fabricated, and supported to meet your project requirements. With our EPC support, you can rely on us, LineCore Pipes Group, your trusted partner in Composite Piping Systems!

FAQs

1- What are the main standards for GRE pipes?

GRE pipes follow global standards such as ISO 14692 and API 15HR for high-pressure applications, including oil and gas pipelines.

2- Can GRE pipes handle high temperatures?

Yes, they can handle up to 95 °C. If additives come into play, it can go above 1000 under limited conditions.

3- What tests are required for GRE pipes?

Visual inspections, dimensional checks, Barcol hardness, and hydrostatic tests at 1.5x design pressure.

about

The Author

Farshid Tavakoli is a seasoned professional in engineering and international trade. Holding degrees in Electrical Engineering, Mechatronics, and a Doctorate in Business Administration (DBA) from the University of Lyon, he also has a strong background in industrial automation and production line technologies.

For over 17 years, he has led an international trading company, gaining deep expertise in commercial solutions tailored to industrial needs. With more than 8 years of active involvement in infrastructure development, he specializes in the supply of electromechanical equipment for water and wastewater treatment plants and transfer projects.

Together with comapny expert team, he now provides consultancy and integrated solutions for sourcing and implementing complex infrastructure projects across the region.