Are the effluent pipes the same as sewer pipes? No! But what’s the difference? An effluent pipe transports cleaner water coming from multiple sources, such as septic tanks, wastewater treatment systems, or agricultural lagoons. To replace old metallic pipes in the water infrastructure or the expansion of urban areas in metropolitan cities, a brand-new solution was required. That’s where effluent piping systems change their materials to more affordable and resistant pipes.

In this article, we’ll show you how composite pipes can elevate the pipelines through their magnificent characteristics. Stay tuned till the end.

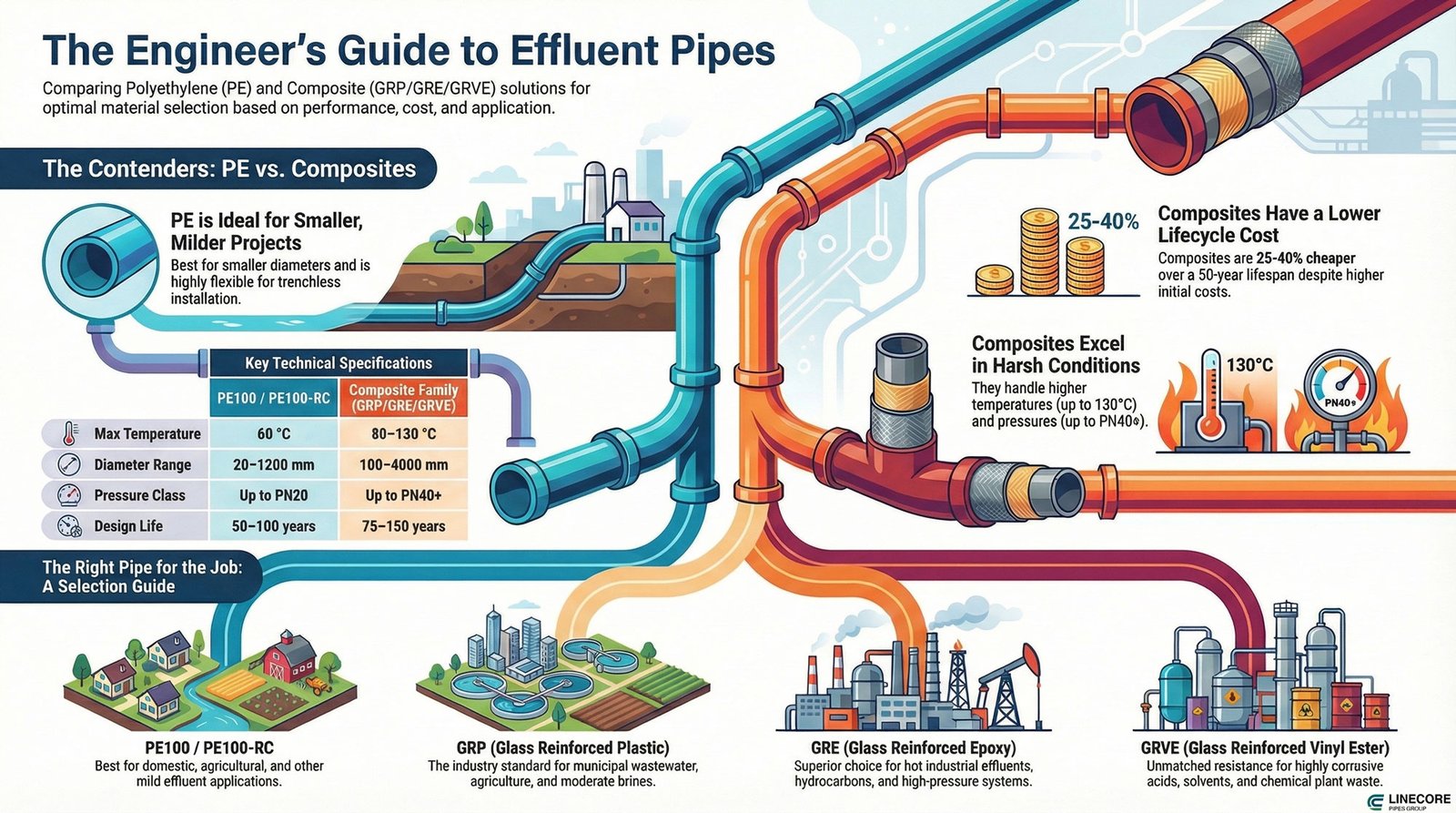

Effluent pipe infographic (Source: PipeLineCoreGroup.com)

What Is Exactly Effluent? Types And Compositions

Effluents indicate what the pipe materials must include. From domestic and residential ones to desalination brines, each requires a specific pipe to resist the corrosive environment and be cost-effective at the same time.

Domestic and Residential Effluent

Once the septic tanks are settled and the liquid is clear with no solid particles, though it includes a rich amount of H₂S (this may result in acids and further corrosion), under anaerobic environments. Here are its parameters:

- TSS <150 mg/L

- BOD₅ 100–250 mg/L

- pH 6.8–7.5

Agricultural Effluent

This type mainly comes from the dairies or livestock conditions that have such strong wastewater from parlors and manure storage.

| Parameter | Typical Range |

|---|---|

| BOD₅ | 1,000–8,000 mg/L |

| Ammonia-N | 200–1,000 mg/L |

| Suspended solids | High (fibers, sand) |

| pH | 6.0–9.0 |

| Additional issues | Fats, oils, abrasive particles |

Industrial Wastewater

In this case, it varies from food waste to highly chemical discharges in the chemical processing. These materials seem to be acids, solvents, heavy metals, or sulfuric compounds that are all converted to acids at the end and cause corrosion in the pipes. (Source: ScienceDirect)

Desalination Brine and High-Salinity Concentrates

Reverse-osmosis rejects streams with TDS 50,000–80,000 mg/L and chloride levels up to 45,000 mg/L, often combined with residual anti-scalants and oxidants.

Effluent vs Sewage vs Greywater: What’s the Difference?

Raw sewage contains solids or pathogens, while graywater is all about what remains of the toilet waste. Then, effluent water is all that fluid with no particles included for further treatments or discharges that are under the control.

Now check the table below for the probable dilemmas that can be caused by effluents for the pipes during their lifetime:

| Challenge | Main Cause | Consequence if Ignored |

|---|---|---|

| Corrosion | H₂S, chlorides, pH extremes | Leaks, pipe failure |

| Abrasion | Grit, sand, fibres | Wall thinning, rupture |

| Biofouling | Organics, stagnant flow | Blockages, H₂S, odour |

| Regulatory non-compliance | Leakage, discharge breaches | Fines, shutdowns |

What Are the Applications of Effluent Pipes?

Effluent pipelines with their good corrosion and pressure resistance can be used through many use cases, and they will be free of cracks or degradation for decades.

- Municipal Wastewater Transport: To transport the effluents with no solids included from treatment systems to the reuse applications in low-pressure conditions with low risk of pipe deformation.

- Septic System Outflows: As noted in Amiblu, whether STEG (Septic Tank Effluent Gravity) or STEP (Septic Tank Effluent Pumping) in both large and small diameters, these pipes can handle them with their smooth inner surface that reduces the need for extra pumping energy.

- Agricultural Effluent Networks: What remains from the dairy, piggery, or poultry wash-downs for various post-uses like fertigation or lagoons via pipes like PE or GRP pipes.

- Industrial effluent lines: This type mainly includes the aggressive chemicals (acids, alkalis, solvents) that require such resistant effluent pipes like GRVE, which the resin combo saves the pipe from corrosion.

- Disposal Lines: In both under- and above-ground installation of effluent pipes, which must keep the clear flow among the long-distance sites like ocean outfalls or evaporation ponds.

- Desalination Effluent Transport: In brine discharges with high pressure and saline conditions, a GRP pipe or GRE can work the best for reverse-osmosis operations.

- Recycled Water Systems: Purple pipe networks send tertiary-treated wastewater for irrigation, cooling in factories, or recharging groundwater. They meet non-potable reuse standards.

What Type of Effluent Pipe Systems Include?

There are several elements that influence the choice of effluent pipes in each piping system. Let’s check them and define the best way to design these lines.

➢ STEG: Septic Tank Effluent Gravity

One of the oldest gravity lines for septic lines is where the downhill flow requires the least pumping energy in sites with lower sloping conditions.

➢ STEP: Septic Tank Effluent Pumping

In high-pressure septic tanks with an extra requirement of mumping for the continuous flow, a no-lot grinder can be helpful, which decreases the chance of excavation and improves the flow rate.

➢ SFS: Solids-Free Sewer

It’s the same as STEG but different in the screening and pipe diameter sizes. For instance, it could include smaller pipes that are free of solid particles sticking on inner surfaces in deeper trenches. (Source: ResearchGate)

➢ Hybrid Sewer Systems

This combination of effluent systems of both gravity lines and the main lines can help to adapt the whole system to specific topography states.

➢ The Case of Desalination Effluent

In brine disposal lines, the saline condition and highly pressurized flows require such a resistant pipeline. Based on previous projects, GRP or GRE pipes can be aligned with the diffusers in long routes and extreme conditions.

➢ How to Compare Pressure and Gravity Effluent?

Check the table below to understand gravity and pressure effluent systems deeply via various aspects like pipe diameter, costs, energy use, etc.

| Aspect | Gravity (STEG/SFS) | Pressure (STEP) |

|---|---|---|

| Pipe diameter | 100–200 mm | 50–150 mm |

| Slope required | 0.5–2 % | None |

| Trench depth | Deeper | Shallower |

| Excavation volume | High | 60–80 % less |

| Energy use | Zero | Low (pump) |

| Best terrain | Flat to downhill | Any (flat, hilly, rocky) |

| Capital cost | Higher trenching | Lower pipe + pumps |

Gravity = cheap to run, needs slope.

Pressure = smaller pipe diameters , can be installed anywhere.

Pipe Materials Used in Effluent Systems

In this section, we’ll show you how to choose the most relevant pipeline to your project demands, which can last for over 50 years with no corrosion, cracks, or leakage. There are two main options: composite pipes and PE pipes. Let’s check which one works the best.

Polyethylene Pipes

As the most thermally stable and pressure-resistant thermoplastic pipe type, which includes PE80, PE100, and PE100-RC, PE pipes contain further characteristics mentioned below:

- Flexibility: Elongation >500 %

- Chemical resistance: pH 1–14

- Buried life: 50–100 years

- Delivery: Coils up to 500 m

- Pressure ratings: PN8–PN20 (SDR17 to SDR9)

- PE100-RC bonus: Top slow-crack & point-load resistance

Use Cases of PE Pipes

PE pipes are used in agricultural effluent lines, STEP/STEG pressure sewers, recycled water lines, and low/medium-pressure urban water systems.

Where Are Their Uses Limited?

They can only tolerate up to 60 °C and can not handle oxidation and aromatic hydrocarbons.

Composite Pipes: How To Surpass PE Pipes In The Case Of Effluent Pipes

Composite pipes include several pipe types, but the best category among all of them that can handle sewer and effluents effectively is the GRP family.

What Exactly Are Composite Pipes Made of?

Composite pipes are made of fiberglass reinforced with a resin matrix, and some additives that help them to resist extreme temperatures and UV light with no degradation.

What Are The Main Manufacturing Processes Of GRP Pipes?

They are made of glass fiber and resin types such as vinyl ester, polyester, and epoxy via methods like filament winding (the most-used one), centrifugal casting, pultrusion, and hand lay-up for more customized pipe shapes. These processes are rooted in the corrosion-free, strength, and lightweight pipes that can withstand heavy loads for over 50 years.

1. GRP Pipes (Glass Reinforced Plastic): The Industry Standard

GRP pipes with a polyester resin base provide less resistance compared to the other types of composite pipes. These pipes are mainly made by filament winding to make such a smooth inner surface in the global use cases.

- No reaction with H₂S, pH 1–14, or 70,000 mg/L salinity

- Over 50 years of lifespan and up to 100 years in certain conditions

- Diameter range from 100-4000 mm in length of 1 to 12 meters

- High strength-to-weight ratio that makes the handling and installation easier

What Are the Typical Applications of GRP Pipes?

They can be used in the effluent systems like urban effluent lines, agricultural effluent transport, desalination brine outfalls, and industrial wastewater networks.

Economical Point: GRP pipes are taking the responsibilities of about 45% of the global share of large-diameter wastewater and brine piping systems (2024–2030 CAGR 7.2 %).

2. GRE Pipes (Glass Reinforced Epoxy): The Highest Thermal Tolerance

GRE pipes add epoxy resin that contains the highest resistance among all resin types. This type mainly handles 110–130 °C fluids. GRE wins GRP in cases below:

- 30–50 % higher pressure ratings (up to PN40 standard)

- Superior performance in hot, chemically aggressive industrial effluents

Technical Insight: GRE is the best option among all composite pipes and PE pipes where the hydrocarbons turn to aromatic combos and the temperature goes higher than 70 °C.

3. GRVE Pipes (Glass Reinforced Vinyl Ester): The Best Case for Corrosion Resistance in Aggressive Conditions

GRVE combines the epoxy resin and vinyl ester to double the resistance against chemicals like acids, alkalis, and solvents in cases where sour gases or hydrocarbons react and convert to acids. Here are its applications in the case of effluent systems:

- Mining acid mine drainage

- Pulp & paper black liquor lines

- Chemical plant waste with mixed oxidants

- Aggressive fertilizer effluents.

Why is GRVE better than its alternatives?

GRVE pipes are more expensive than GRP pipes (about 15-20%), but they need no extra alloy covering or thick linings under extreme conditions.

Why choose GRP/GRE/GRVE over PE pipes?

Firstly, when the diameter is higher than 300 mm, the temperature is greater than 60 °C, or the effluent contains hydrocarbons, strong oxidants, or chlorides greater than 20,000 mg/L, choose GRP/GRE/GRVE instead of PE. Also, they surpass PE pipes with the properties below:

- Composites are 25–40% cheaper over 50 years, even though they cost more up front.

- Composites are universal, while PE is limited in the case of corrosion resistance; for instance, GRVE can handle very acidic conditions with no protective layers applied.

- Composites can handle pressures up to PN40 and temperatures up to 130 °C. PE can only handle pressures up to PN20 and temperatures up to 60 °C.

- PE wins on small-diameter trenchless composites, though, can handle both large-diameter buried or above-ground.

| Parameter | PE100 / PE100-RC | GRP / GRE / GRVE Family |

|---|---|---|

| Corrosion resistance | Good (pH 1–14) | Outstanding (all chemicals & brines) |

| Max temperature | 60 °C | 80–130 °C |

| Diameter range | 20–1200 mm | 100–4000 mm |

| Design life | 50–100 years | 75–150 years |

| Pressure class | Up to PN20 | Up to PN40+ |

| Lifecycle cost (50 yr) | Higher maintenance | 25–40 % lower |

| Best for | Small-diameter, mild service | Large-diameter, harsh effluents |

Advantages of Composite Effluent Pipes (GRP / GRE / GRVE)

Once we’ve figured out how composite pipes win RP pipes, it’s time to get closer to their beneficial aspects, then check the points below to make sure your pipe selection is reliable enough.

- Corrosion resistance: Composite pipes have no reaction with H₂S, chlorides, acids, or 80,000 mg/L brine.

- Long Lifespan: They last over 50 years, which is approved by ASTM D2996, while they may last up to a century in certain conditions.

- Maintenance Requirement: Composite pipes need no painting, no cathodic coating, or liners on the inner surface to be resistant to corrosion.

- Lightweight: Their high strength-to-weight ratio allows them to be handled, installed, and transported easily.

- Superior hydraulics: Their smooth inner surface, which is made via the centrifugal casting process, decreases the dependence of the system on extra pumps.

- Life Cycle Cost: They are way cheaper than metallic or non-metallic pipes (around 25-45% to steel, ductile iron pipes, or concrete).

Standards & Certifications of Effluent Piping Systems

A modern solution for the effluent pipelines needs to be verified by global standards and guidelines. Below, a table contains the most-used standards and compliance for the composite pipes in the case of effluents.

| Standard | Pipe Type | Final Purpose |

|---|---|---|

| ISO 9001 / 14001 / 45001 | All manufacturers | Quality, environment & safety |

| EN 1796 & EN 14364 | GRP pipes | Design, stiffness & long-term performance |

| ASTM D3262 / D3517 | GRP sewer & pressure | Material qualification & pressure rating |

| AS/NZS 4130 | PE pipes | Polyethylene pressure pipe specification |

| Lilac / Purple coding | Recycled water lines | Universal non-potable identification |

Sizes And Pressure Ratings For Effluent Pipes

GRP and composite pipes come in sizes from 75 mm to 4000 mm in standard production. They can also be made to order in pressure classes PN6, PN10, PN16, PN20, PN25, PN32, and higher. Stiffness classes (SN) go from 2500 Pa to 10,000 Pa or more for deep burial or traffic loads.

PE pipes usually range in size from 20 to 1200 mm and come in coils of 50 to 100 m (for smaller diameters) or straight lengths of 6 to 20 m (for larger sizes).

Smooth internal surfaces control flow capacity (Hazen-Williams C = 150 for GRP vs 140 for PE), which means that GRP can handle higher speeds and smaller diameters for the same job than concrete or steel.

Jointing Methods and Fittings for Effluent Pipes

The jointing methods of effluent pipes include both PE and composite pipes to make leak-free connections.

For PE Pipes

- Camlock fittings make it easy to connect and disconnect pumps or other temporary connections.

- Compression fittings are mechanical joints that don’t need heat for small diameters.

- Electrofusion fittings are welded couplers, tees, elbows, and reducers that make fully fused, uniform joints that are rated to the same PN as the pipe.

These choices make it easy to put things together quickly and without tools, which is great for agricultural and STEP systems.

For pipelines made of GRP and composites

GRP couplings have a double-bell elastomeric seal that makes it easy to put them together quickly.

- Flanged joints are bolted together for above-ground or removable parts. (Source: Scribd)

- Lamination joints are made by hand-laying fiberglass to make strong, permanent connections.

- Restrained and non-restrained thrust blocks or locked couplings for pressure spikes

- Gaskets that are resistant to chemicals, such as EPDM, Viton, or nitrile, are chosen to match the chemistry of the effluent.

Even in very corrosive brine or industrial settings, composite fittings stay strong for a long time.

Installation Techniques for the Effluent Pipes

To choose the correct installation method, multiple aspects must be considered.

● Trench vs Trenchless Installation

In an open-trench installation, try to place pipes carefully and backfill them completely to avoid cracks. Then, in the trenchless ones, like micro tunneling and horizontal directional drilling (HDD) in the rivers or roads with low downtime or gravity lines with large diameters.

● Bedding & Backfilling

Try to bed the pipes after correct placement to reduce the chance of any movement or further deformation.

- 150 mm granular bed

- Haunch to 75 % height

- 300 mm layers, 95 % Proctor

- No rocks >50 mm

● Above-Ground vs Buried Designs

Buried is the default. Above-ground uses saddles, expansion loops, and a UV-protective coating where access for inspection is needed.

● How to Integrate Pumps into STEP Systems

Effluent pumps (either progressive cavity or centrifugal) go into on-lot vaults that have high-level alarms and risers that can be quickly disconnected.

● Handling, Joining, and Quality Checking

Use nylon slings, make sure the joints are perfectly lined up, and test the pressure at 1.5 × PN for an hour, plus check the deflection for GRP.

Effluent Disposal Methods

Disposing of wastewater safely and in accordance with the law closes the cycle and protects ecosystems. Ocean Disposal (Coastal) Multi-port diffusers on brine discharge pipes quickly mix the brine with the water.

- Options for the Inland: Evaporation ponds are lined basins that collect solar energy.

- Land Application: Irrigation and fertigation recycle nutrients by treating the soil.

- Risks to the Environment: Salinity accumulation, groundwater pollution, and eutrophication.

- Mitigation of GRP/Composite: Walls that are not permeable and do not corrode stop leaks and seepage for more than 75 years.

Challenges & Limitations of Effluent Pipe Systems

Every pipeline has its own flaws; effluent pipes are not such exceptions. Here are some reasons why these pipes might fail:

Polyethylene (PE): It costs less up front, but it can only handle temperatures up to 60 °C and is sensitive to hydrocarbons, oxidants, and UV light. In installations that are point-loaded or scratched and don’t have RC grades, cracks can grow slowly.

Composite (GRP/GRE/GRVE): Costs more up front (20–50% more than PE) and needs skilled workers to make laminated joints. When moving large-diameter pipes, you need to be careful and use cranes. Rigidity requires careful bedding and monitoring of deflection.

Site-specific problems, like aggressive soils, seismic zones, or high groundwater, may need more anchoring or stiffness upgrades. Warranties are voided, and the life of any pipe is shortened by bad installation.

Effluent Pipe Material Selection Guide

In the last section, we provide engineers with a table fully designed to select the most reliable pipeline for their sewer and effluent project.

| Parameter | PE100 / PE100-RC | GRP (Polyester) | GRE (Epoxy) | GRVE (Vinyl Ester) |

|---|---|---|---|---|

| Best effluent types | Domestic, agricultural, mild sewage | Municipal, agricultural, moderate brine | Industrial, hot effluents, hydrocarbons | Highly corrosive acids, solvents, bleach |

| Chemical resistance | Good (pH 1–14, no strong oxidants) | Excellent (H₂S, brines to 70k mg/L) | Superior (aromatics, higher temps) | Best-in-class (concentrated acids/alkalis) |

| Max temperature | 60 °C | 80 °C | 110–130 °C | 100–110 °C |

| Diameter range | 20–1200 mm | 100–4000 mm | 100–3000 mm | 100–2000 mm |

| Pressure rating | Up to PN20 | Up to PN32+ | Up to PN40+ | Up to PN32+ |

| Design life | 50–100 years | 75–100 years | 75–100 years | 75–100 years |

| Relative initial cost | Low | Medium | Medium-high | High |

| Lifecycle cost (50 yr) | Higher in harsh conditions | Lowest for large/moderate | Low for industrial | Lowest for extreme chemistry |

| Installation ease | Excellent (coils, trenchless) | Good (lightweight, rigid) | Good | Good |

- Summary: Check each pipeline based on your project demand to adapt the design and material options for a successful piping system over time.

Ready to Select the Right Effluent Pipeline?

For expert supply of premium GRP, GRE, and GRVE pipes designed for your urban, agricultural, industrial, or desalination project, contact LineCore Pipes Group today. contact info@pipelinecoregroup.com for consultations, quotes, and solutions that represent decades of performance with no corrosion included.

FAQs

1- How long do composite effluent pipes last?

They usually last over 50 years and can still be working for a century under certain conditions.

2- When choosing GRP over PE?

For >300 mm diameter, >60 °C, brines, H₂S, or 75+ year lifecycle priority.

3- Are composite pipes used in desalination plants?

Yes, GRP and GRE are the most-used industry standards for hypersaline brine pipelines with or without UV-resistant or fire-retardant coatings.

about

The Author

Farshid Tavakoli is a seasoned professional in engineering and international trade. Holding degrees in Electrical Engineering, Mechatronics, and a Doctorate in Business Administration (DBA) from the University of Lyon, he also has a strong background in industrial automation and production line technologies.

For over 17 years, he has led an international trading company, gaining deep expertise in commercial solutions tailored to industrial needs. With more than 8 years of active involvement in infrastructure development, he specializes in the supply of electromechanical equipment for water and wastewater treatment plants and transfer projects.

Together with comapny expert team, he now provides consultancy and integrated solutions for sourcing and implementing complex infrastructure projects across the region.