In this world, where we’re facing the water shortage more than ever, it’s needed to make an alternative source for water, whether potable water or industrial water. Then, it’s predicted that the market of desalination will be around $19-20 billion for this year, with a sharp growth in the next few years. Pipelines are the essence of the desalination plants in brines, seawater, or fresh water in the harsh marine conditions.

This post introduces the most-used pipes for desalination systems that can tolerate high pressure and high temperature, and aggressive environments for decades.

Overview of Desalination Systems

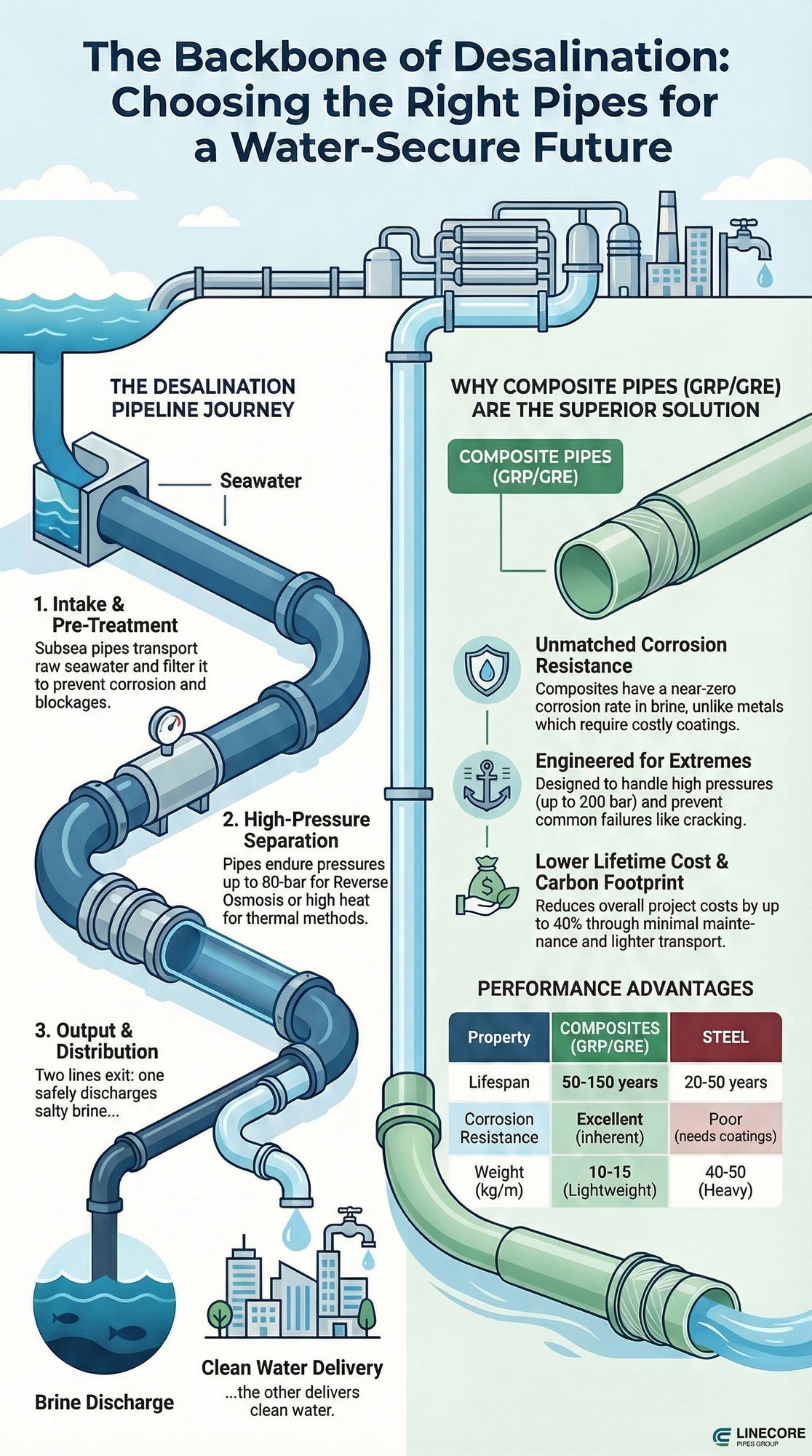

Desalination Pipes infographic (Source: Pipelinecoregroup.com)

The conversion of seawater to potable water is possible through the desalination process. There are three methods that desalination works through, from SWRO and MFS to MED, to move the fluids through pipes in several steps.

What Are the Major Desalination Technologies?

Engineers are looking for quick and reliable methods to release salt from the water. Here are the three main methods:

SWRO (Seawater Reverse Osmosis) pushes water through membranes under high pressure to filter out salts, making it popular for its energy efficiency in coastal plants. SWRO leads the way with over 60% of global share due to its consistent effectiveness. (USBR.gov)

MSF (Multi-Stage Flash) heats seawater and flashes it into vapor across stages, condensing pure water, ideal for areas with cheap heat sources.

MED (Multi-Effect Distillation) boils water in multiple chambers, reusing heat from one to the next, which saves energy over older thermal methods.

- Technical Insight: In SWRO, the rate of recovery goes up to 50%, while the pollution from organic sources may reduce it and require pre-treatment to keep the flux rate above 15 L/m²/h.

Pipeline Roles in Each Stage

Pipe can adjust the flow rate in each step based on the demanded function of them.

- Seawater Intake: Transmission of seawater by subsea lines to keep the water safe.

- Pre-treatment: Filtration of seawater before the core process, with no corrosion added to the pipes or the water.

- Reverse Osmosis or Thermal: High-pressure lines for RO or hot fluid pipes for MSF/MED manage the salt separation.

- Brine Reject: Takes the salty wastes to the ocean via brine outfall pipelines.

- Permeate Distribution: The last stage transports the clean and drinkable water to the supply points.

Environmental and Engineering Challenges

Brine discharge increases salinity, which is bad for marine life, and SWRO’s use of 2.5–4 kWh/m³ of energy increases emissions. Corrosion, biofouling (which cuts flow by 20–45%), and surges are all problems. (Source: American Water Chemicals)

To help MENA’s green initiatives, there are solutions like diffusers and composite pipes for seawater.

Types of Pipelines in Desalination Plants

Desalination plants require pipes that stand in the harsh and extreme conditions of offshore and marine environments. These pipes must handle seawater, high-pressure processes, and chemical lines, with materials chosen to fight corrosion and endure marine stresses.

Seawater Intake Pipelines

In the onshore and subsea setups, there are some pipes that transport the raw seawater. These pipes must be resistant to corrosion, UV light, or harsh and massive ocean waves, which may cause deformation or degradation.

GRP and GRV pipes are one of the best options in this case, which are light and highly resistant to these horrible cases, while HDPE can be another option, though it may get deformed under the waves.

- Technical insight: Designs factor in flow velocities under 0.5 m/s to curb marine growth that uses the Manning equation to check the hydraulic sizes.

Reverse Osmosis (RO) Process Piping

In this case, pipes must stand under an 80-bar pressure and have a smooth inner surface that shows no corrosion or reduction in the flow rating.

- High-pressure demands: Pipes must handle both internal and external pressures with no fatigue.

- Ideal characteristics: Smooth inner surface for better flow and low roughness to save energy

Brine Outfall Pipelines

They release corrosive brine, often with diffusers for eco-friendly considerations to avoid salinity hits. GRP surpasses metal pipes in the case of resistance to corrosion from high salts.

- Handling brine: To keep the flow high with no interruption.

- Environmental compliance: Multi-port diffusers achieve dilution ratios >20:1.

Permeate Distribution Pipelines

As noted in the US Environmental Protection Agency, in the water treatment lines, a pipe with low-pressure toleration and the ability to make no changes to the water quality based on NSF 61 (leach or taste-off).

- Technical insight: Pipe sizing follows the Hazen-Williams equation, C=150 for smooth composites, boosting capacity over rougher alternatives.

Chemical Dosing & Instrumentation Lines

Exposed to acids, coagulants, and chlorine, these fluids require a pipe to handle them with no degradation, unlike GRE pipes, which show no damage over time.

Composite Pipe Systems for Desalination: A Smart Solution for Long-Term Performances

Composite piping systems are such reliable and long-lasting choices for desalination plants, and at each stage. Our pipelines can be designed based on your project demands and scale as an innovative solution from LineCore Pipes Group.

Materials Explained: GRP, GRV, GRE, or RTP

Composite pipes are made from fiberglass reinforced with a resin matrix. The changes in the resin type result in specific characteristics shown below.

● GRP (Glass Reinforced Polyester)

GRP pipes are made of glass fibers and unsaturated polyester resin via various methods, such as filament winding, to make such a resistant pipe under medium pressures and corrosive lines.

These pipes are the best options where the corrosion risk is lower and a more cost-effective option is needed.

● GRE (Glass Reinforced Epoxy)

These pipes replace the polyester with epoxy to improve the thermal stability and pressure resistance in high-pressure systems (offshore and onshore).

SWRO can handle temperatures above 80°C. (Source: Scribd)

● GRV (Glass Reinforced Vinyl Ester)

These pipes are covered by vinyl ester resin that improves the resistance against acids, alkalis, chlorine, and solvents, with no corrosion added to the pipes. GRV is known as the best option for desalination plants and is popularly used in the GCC area.

While in GRVE pipe with adding an epoxy resin to the material, thermal stability goes higher and makes it superior to its alternatives.

● RTP (Reinforced Thermoplastic Pipe)

RTPs are created from the thermoplastic liners and fiber reinforcements that make them perfect for subsea pipelines to release the water with a minimal number of impurities.

How Engineers Benefit From Composite Pipes In The Desalination Plants?

GRP pipe family (GRP, GRV, GRE) is such a super material for various applications, including desalination plants with high risk of UV exposure, corrosion, and cracks under high pressure. Key advantages:

- Corrosion resistance

- High-pressure handling

- High strength-to-weight ratio

- Durability

- Cost effectiveness

- Long lifespan

Now, let’s compare GRP family pipes with other options to see if there’s any chance to choose those long-lasting pipelines as desired:

| Property | GRP/GRE | HDPE | Steel | Duplex Steel |

|---|---|---|---|---|

| Corrosion Resistance | Excellent (inherent) | Excellent (inert) | Poor (needs coatings) | Excellent (alloyed) |

| Pressure Handling | High (up to 200 bar) | Medium (up to 25 bar) | Very High (300+ bar) | High (200 bar) |

| Weight (kg/m for DN300) | 10-15 | 8-12 | 40-50 | 45-55 |

| Life Span (Years) | 50-150 | 50-100 | 20-50 | 50-100 |

| Installation Ease | High (light, joints) | Very High (flexible) | Low (heavy, welding) | Medium (welding needed) |

| Initial Cost ($/m) | 50-150 (moderate) | 30-100 (low) | 20-80 (low) | 100-200 (high) |

| Max Temperature (°C) | 120-130

(Upper than 1000 if additives added) |

60-80 | 200+ | 250+ |

| Flexibility | Low-Medium (rigid) | High (ductile) | Low (rigid) | Low (rigid) |

| Chemical Resistance | Excellent (resin-based) | Excellent (broad range) | Poor (reactive) | Very Good (resists acids) |

| Abrasion Resistance | High (composite structure) | Moderate (smooth surface) | High (durable) | High (tough alloy) |

| UV Resistance | Moderate (needs coating) | High (inherent) | N/A (not exposed) | N/A (environmental resistant) |

Then, choose GRP pipes in all stages of your modern and functional desalination systems to work like the first day for decades.

Key Design Considerations of Chosen Pipelines in Your Desalination Plants

Once you’re stepping into the design process of your desalination plant, it’s time to consider several components that may influence the final product.

- Pressure class (PN) represents how the pipe will stand under operational loads with no deformation included over time in changing stages.

- Jointing systems contain multiple methods to ease the process at every site with no leakage.

- Thermal expansion does matter when the stress should be avoided in the changing thermal states up to 120°C in brine outfall pipelines. (Source: REXResearch)

- Trenching and burial depths show how pipes are backfilled to be protected from unwanted movements and hard rocks that cause damage to the pipe’s body.

- Pipe Stiffness or SN shows how pipes will act under heavy loads with no cracking, which GRE with complex design beats alternatives.

- Lastly, the choice of resin types in the GRP family lets them be away from UV-resistant layers, which makes other pipes expensive and partly fail under the sun’s exposure.

| Design Consideration | Description & Key Points | Technical Insight |

|---|---|---|

| Pressure Class and Surge Handling | Up to 200 bar in SWRO; avoids water hammer from flow changes. | Formula spots pressure jumps; limit speed to 1.2 m/s. |

| Jointing Systems | Lamination (GRP), butt & wrap (HDPE), flanges; no leaks. | Composite bonds prevent joint rust. |

| Thermal Expansion, Flexibility, and Anchoring | GRP coeff. 20-30 × 10⁻⁶ /°C; loops/anchors for 120°C max. | Calculate stretch: growth rate × length × temp change. |

| Trenching and Burial Depths | 18-60 inches deep; smooth backfill. | At least 0.6m bury per standards. |

| Pipe Stiffness and Soil Interaction | SN values prevent buckling; <5% bend for GRE. | Equation ensures <5% warp under soil load. |

| UV Exposure and Coatings | Epoxy coats or bury to stop wear. | Boosts life 10-20 years in sun-heavy areas. |

Corrosion & Durability Performance of Pipelines Under The Saline Conditions

In desalination plants, common failures include localized chloride attack or corrosion in jointing areas, which can cause cracking and leaks.

Composite pipes like GRP and GRE pipes are the best options and surpass metal pipes in saline and marine environments, where highly saline water and acidic conditions can accelerate corrosion. Check the table below to understand how GRP pipes beat steel pipes in modern systems:

| Aspect | Metals (e.g., Steel) | Composites (e.g., GRP/GRE) |

|---|---|---|

| Failure Modes | Pitting, crevice, chlorine attack | Matrix cracking, abrasion only |

| Corrosion Rate | 0.1-1 mm/year in saline | Near zero in brine |

| Protection Needed | Cathodic, coatings | None |

| Lifespan | 20-50 years | 50-150 years |

Sustainability & Cost Efficiency: Following the Green Trends

GRP pipes are such eco-friendly choices for desalination systems, which themselves follow the same policies. The considerations below show how GRP pipes are included in the 2026 green selection.

A. Lifecycle Cost Comparison: Where GRP Beats Metals

GRP pipes include higher initial costs, but the overall cost is always lower than metal pipes like steel due to their lower need for maintenance or repair, resulting in up to 40% savings.

B. Energy Savings from Low-Friction Bore

The smooth inner surface made from the centrifugal casting is the key to helping GRP pipes have better flow rate IN SWRO systems.

C. Carbon Footprint Reduction in Transport and Maintenance

The transport emission of metal pipes is much higher than GRP pipes, which has a 30-60% reduction in transportation and no need for heavy cranes. GRP pipes make them a green choice for desalination plants.

Elevate Your 2026 Desalination Projects Today!

Looking for leak-free pipelines in your desalination plant’s infrastructure? Contact an expert consultant at LineCore Pipes Group for customized pipes to your project demands! contact wi info@pipelinecoregroup.com today for quotes and expert advice.

FAQs

1- What makes GRP pipes ideal for desalination?

GRP pipes are lightweight and corrosion-resistant when exposed to seawater in heavy waves of the ocean.

2- How do composites compare to HDPE in cost?

They include a higher initial cost, but lower overall costs due to the minimal need for maintenance.

3- Can GRE pipes handle high pressures?

Yes, up to 200 bar for SWRO systems.

4- What are the installation considerations for subsea pipelines?

Faster with lightweight composites and more reliable with various jointing methods and fittings with the same materials.

5- Which one is better for desalination plants, GRP or Steel? And why?

GRP pipes beat steel pipes due to their lightweight and corrosion resistance with no protective layer required.

about

The Author

Farshid Tavakoli is a seasoned professional in engineering and international trade. Holding degrees in Electrical Engineering, Mechatronics, and a Doctorate in Business Administration (DBA) from the University of Lyon, he also has a strong background in industrial automation and production line technologies.

For over 17 years, he has led an international trading company, gaining deep expertise in commercial solutions tailored to industrial needs. With more than 8 years of active involvement in infrastructure development, he specializes in the supply of electromechanical equipment for water and wastewater treatment plants and transfer projects.

Together with comapny expert team, he now provides consultancy and integrated solutions for sourcing and implementing complex infrastructure projects across the region.