One of the most-heard dilemmas of piping systems is when pipes get corroded. This matter increased the cost of corrosion globally to over $2.5 trillion across all industries. That’s why engineers, contractors, and project managers are turning to modern choices, including the ability to resist harsh and corrosive environments.

In this article, we’ll discuss all existing types of corrosion-resistant pipes, including a complete guide to the right selection based on your project demand.

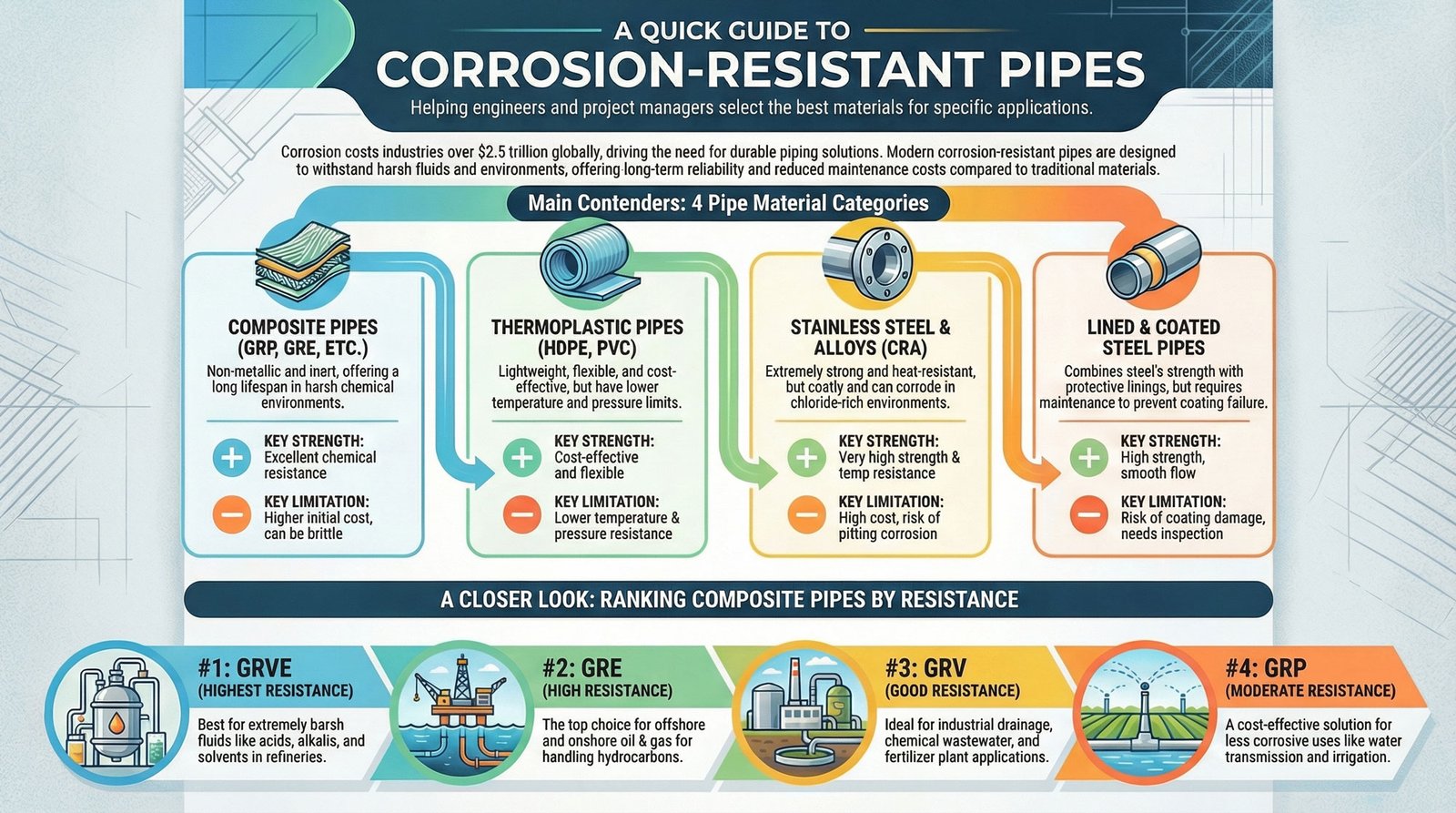

Corrosion resistant pipes infographic (Source: PipeLineCoreGroup.com)

What Exactly Is a Corrosion-Resistant Pipe?

Corrosion-resistant pipes are designed to handle various types of harsh fluids, from acids and alkalis to saline or sewer water.

This property avoids environmental corrosion from chemicals or electrochemical reactions that stem from the extra lining and coatings or the essence of each pipe material, as the GRP family does.

Internal vs. External Corrosion

Internal corrosion comes from the fluids flowing inside the pipes during their lifetime. For instance, steel pipes are more likely to react with most fluids over time. External corrosion is caused by the surrounding environments of pipelines, such as aggressive soils or seawater.

Consider that both of them may result in failure of that piping system and increase the cost of maintenance as time goes by.

What Are the Real-World Examples of Corrosion Resistance?

Pipelines may show corroded areas when placed at the wrong site with no protection. Here are some of those places where setting the pipelines requires thoughtful protective plans.

- Seawater: The saltwater and marine conditions are one of those areas that, regardless of avoiding the UV exposure, themselves cause pipes to get corroded over time. In desalination plants, GRV/GRVE pipes are used as modern choices with no corrosion included.

- Chemicals: In chemical plants, both internal and external corrosion threaten the pipes, and GRV pipes covered by layers of vinyl ester resin can be helpful in this case, too.

- Oil & Gas: In the case of harsh and high-temperature use cases, where corrosive aspects add a burden to this difficulty, GRE pipes, coated with epoxy resin, are the top choice for use in brand-new infrastructures.

- Wastewater: Lastly, the case of wastewater and sewerage requires such resistance pipes that, from more general uses to highly corrosive ones, the selection can be changed from GRP to GRV pipes.

What Are Different Types of Corrosion-Resistant Pipes and How Do They Work?

Corrosion-resistant pipes come in various materials, each with specific advantages and applications. Here’s an overview of the most common types, their structures, and why they resist corrosion.

Composite Pipes: GRVE, GRE, GRV, GRP

Composite pipes are made of fibers and a resin matrix. The type of fiber in this case is reinforced glass fibers, and the resin type can vary from polyester to vinyl ester and epoxy. These non-metallic solutions have been changing the game for decades due to their long lifespan. Here’s the structure:

- Liner: Inner layer that consists of resin and makes the surface smooth.

- Structural layer: This part includes both resin and glass fiber in the desired strength as the final use case requires.

- Outer Layer: This layer contains a rich amount of resin that protects pipes from UV exposure and corrosion in harsh conditions.

Why Composites Do Not Corrode

The non-metallic and inert system of resin matrix in composite pipes allows them to withstand various damaging environments from oceans to deep trenches. This resin layer prevents them from corroding due to the reaction with saltwater, chemicals, etc.

In metallic pipes, oxidation and electrochemical reactions were common reasons to cause corrosion, which composite pipes pass.

Thermoplastic Pipes: HDPE, PVC/CPVC, PP, PVDF

Thermoplastic pipes are made from synthetic polymers and, as plastic-based pipes, show perfect resistance to corrosion. Also, their lightweight makes them top choices for hard-to-access sites.

But What Are the Pros and Cons of Thermoplastics Selection?

Thermoplastic pipes are lighter than most of their alternatives, which makes the transportation and installation processes easier. Unlike their cost-effective nature, they can withstand high temperatures or pressures.

- Comparison Point: The highest temperature HDPE can tolerate is about 60°C, or PVC fails in high temperatures, whereas GRE pipes can withstand temperatures of more than 1000°C if fire-retardant additives are applied. (Source: Future Pipe)

Stainless Steel & Corrosion-Resistant Alloys (CRA)

Stainless steel and corrosion-resistant alloys (CRAs) like 316L, duplex, and super-duplex steel are used where strength and high corrosion resistance are required. There are other metal choices like nickel alloys or titanium, but the cost of the material is so high that it makes them unaffordable for most cases.

Where Do Stainless Steel & CRAs Shine and Fail?

The strength of metal pipes under heavy loads and durability over time make them a good option in piping systems. However, as noted in ScienceDirect, in places with abundant chloride, the risk of Chloride Stress Corrosion Cracking (SCC) and pitting corrosion is increased and may cause ruinous corrosion.

Lined & Coated Steel Pipes

Steel pipes can resist corrosive conditions with extra linings and coatings that boost the costs and make them less affordable in multiple use cases. Here are the protective materials used in steel pipes:

- Epoxy Lining: Epoxy can make pipes resistant to corrosion and, by its smoothness in the inner surface, reduce the cost of pumping energy.

- Cement Lining: In water systems with a moderate risk of corrosion, it is used to resist internal corrosion.

- PE/PVC Internal Lining: Where steel pipes are chosen for oil and gas or chemical lines, PE and PVC linings provide that protection for a long time.

- External Coatings: Galvanization and PE coatings protect against external environmental damage.

When can failure occur in steel pipelines?

The first signs of corrosion appear when the under-coating corrosion happens, and may result in pipe degradation or further cracks. Then use steel pipes with extra protective layers where chemicals are more moderate.

| Category | Materials | Corrosion Resistance | Strengths | Temp. Resistance | Pressure Resistance | Limitations |

|---|---|---|---|---|---|---|

| Composite | GRP, GRE, GRVE, GRV | Non-metallic, chemical resistant | Lightweight, long lifespan | ~90°C (GRE higher with additives) | Moderate to high | Brittle, expensive |

| Thermoplastic | HDPE, PVC/CPVC, PP, PVDF | Polymer-based, chemical resistant | Flexible, cost-effective | ~60°C (higher for PVDF) | Moderate (1000-2000 psi) | Lower strength, temp. & pressure |

| Stainless & CRAs | 316L, Duplex, Super-Duplex | Chromium oxide film | Strong, high temp. resistance | ~1000°C | High (5000+ psi) | Pitting in chloride-rich environments, costly |

| Lined & Coated Steel | Epoxy, Cement, PE/PVC Lined | Coatings protect metal | Strong, smooth flow | ~80°C (depends on lining) | High | Coating damage risk, maintenance needed |

Comparison of Composite Pipes by Corrosion Resistance

Composite pipes are one of the best options among all corrosion-resistant pipelines. They’re designed to be a way of preventing physical damage. Check all these four cases from the highest resistance to the most moderate one:

GRVE (Glass Reinforced Vinyl Ester – Epoxy Vinyl Ester)

GRVE pipes are the strongest type of composite pipes that can handle extremely harsh fluids like acids, alkalis, and solvents.

- Why is GRVE the best? The resin type is the answer

The combination of resin types, such as vinyl ester and epoxy, allows them to own the characteristics of both these materials and show a higher resistance compared to GRE or GRV pipes.

- Where does GRV pipe work the best?

This perfect resistance to acids, alkalis, chlorides, and industrial wastewater makes them the top choice for chemical processing, where the corrosive substances put pipes into undetectable trouble.

GRE (Glass Reinforced Epoxy)

GRP pipes with glass fibers and epoxy resin take the second place, where they are used in offshore platforms with high resistance to hydrocarbons and brines, like the oil and gas pipelines.

- The case of resistance against H₂S

Sour gases like H₂S that exist in offshore and onshore oilfields require such high tolerance that GRE pipes are the best option and are commonly used in oil and gas plants. (Source: ResearchGate)

GRP (Glass Reinforced Polyester)

Got to the last and least corrosion-resistant among the giant types of composite pipes. The polyester resin used in GRP pipes provides lower corrosion resistance compared to GRV and GRE. However, this rate of resistance works well in less corrosive use cases like:

- Irrigation

- Seawater intake

- Cooling water

- Urban water supply

- Potable water transmission

When it comes to highly corrosive chemicals, GRP pipes are not reliable choices, and switching to GRE or GRV can be more helpful.

| Pipe Type | Corrosion Resistance | Best Applications | Temperature Range | Pressure Rating | Limitations |

|---|---|---|---|---|---|

| GRVE | ●●●●● | Petrochemical, refinery, industrial chemicals | -40°C to 120°C | 10-50 bar | High cost, specific use cases |

| GRV | ●●●● | Effluent, industrial drainage, sewage | -20°C to 80°C | 5-25 bar | Moderate resistance, medium chemicals |

| GRE | ●●●● | Offshore/onshore oilfield pipelines, hydrocarbons | -40°C to 100°C | 10-40 bar | Not suitable for extreme acids/alkalis |

| GRP | ●● | Water transmission, seawater intake, irrigation | 0°C to 50°C | 5-20 bar | Poor for aggressive chemicals |

Why Pipes Corrode: The Science Behind It

There are several mechanisms that result in the pipe’s corrosion, from chemical reactions to cases coming from stress or temperature changes. Let’s figure out how pipes corrode.

1. Chemical Corrosion

Happens when pipes react to the oxygen (mainly in the case of metal pipes), which damages the pipe’s material. Also, chemicals like acids and alkalis caused deterioration and cracks.

Acidic Point: Acids like sulfuric acid (H₂SO₄) or hydrochloric acid (HCl) are increasingly degrading carbon steel pipes.

2. Electrochemical Corrosion

In the seawater, a rich number of chlorides exists that causes corrosion in pipes and reactions with metal pipes, while pipes get galvanized corrosion when two different types of metal interact with electrolytes, and one gets corroded sooner. (Check MDPI)

Pro Tip: The grade of galvanic corrosion depends on factors like electrochemical potential and how conductive the electrolyte is.

3. Microbiologically Influenced Corrosion (MIC)

The presence of fungi, bacteria, or other microorganisms that survive in wet conditions can cause the production of acidic material around the metal pipes. This can cause pipes to corrode over time, for instance, in wastewater pipelines, such as the case of H₂S-damaged pipes.

4. Stress & Temperature-Driven Corrosion

Pipes are mostly under the stress of a corrosive environment that can increase the risk of cracks and their development. Moreover, at higher temperatures, the degradation of metal pipes happens faster than their alternatives, and the deformation of oxide layers causes cracks.

How To Select The Most Reliable Corrosion-Resistant Pipe For Your Project?

There are many factors to consider when choosing the right pipe based on the project demands, such as the type of fluid, temperature, pressure, environmental aspects, and maintenance requirements. In this section, we provide you with a step-by-step guide to choosing the best pipeline.

Based on Fluid Type: from Chemicals to Hydrocarbons

The type of fluid that will be transported by the pipes indicates how resistant the pipe must be or what type of protective layers should be applied.

- Acids and Alkalis: In aggressive cases like acids or similar substances, GRVE, with the combination of vinyl ester and epoxy, provides a superior resistance, while the fiber layers keep the strength under heavy loads.

- Hydrocarbons and Brines: GRE can save the whole project offshore and onshore with no degradation or change in the pipe material over time. In hydrocarbon transmissions, GRE pipes have no reaction with oil, gas, or brines.

- Chemical Wastewater: To handle the Wastewater, consider that the rate of harshness may be changed; for harsher ones, try to use GRV pipes (industrial drainage and effluent discharges), and for more moderate ones, use GRP pipes.

- Seawater / Potable Water: In less aggressive cases, like drinking water or urban water transmissions, GRP pipes are such a cost-effective and durable choice.

Based on Temperature & Pressure

In high-temperature and high-pressure systems, composite pipes, and more specifically, the GRP pipe family, can tolerate a wide range of temperatures. This property makes GRP pipes + additives that can boost this resilience up to a thousand degrees and hundreds of bar pressure.

On the other hand, thermoplastic pipes like HDPE or PVC can tolerate a more limited range of temperature or pressure. If the conditions get extreme, they may fail and show deformations or degradations.

Based on exposure to the environment

Check for the rate of exposure in each environment where you’re placing the pipes; this matter results in the outer corrosion, and in some cases, the final choice of pipe may require extra coatings.

- Soil Corrosiveness: Composite pipes or lined steel pipes work better in areas with very corrosive soil.

- Marine Conditions: GRVE or GRP pipes are great for marine environments because they don’t break down when exposed to seawater or UV light.

- Dynamic Loads Offshore: GRE or GRVE pipes are often used for offshore pipelines because they can handle dynamic loads and high-pressure situations.

Based on the philosophy of maintenance

If you want a solution that doesn’t need a lot of care, composite pipes like GRVE and GRE are the best choice because they last a long time and don’t need much care.

- High-maintenance acceptable? Lined steel pipes are a cheap option for systems that can be maintained regularly, but they need to be checked for wear on the coating from time to time.

Moreover, check the table below to understand how each of the corrosion-resistant pipes may fail and how to avoid such a dilemma:

| Pipe Type | Failure Mode | Cause of Failure | Prevention |

|---|---|---|---|

| Composite Pipes | Delamination | Failure of internal layers | Use higher-quality resin, proper installation |

| Metal Pipes | Pitting Corrosion | Localized corrosion, often due to chloride exposure | Cathodic protection, regular inspections |

| Lined Steel Pipes | Under-Coating Corrosion | Failure of protective lining | Regular coating maintenance, inspection |

| Stainless Steel & CRA | Stress Corrosion Cracking (SCC) | Exposure to chloride and stress | Use stress-relief techniques, proper alloy choice |

How Do Engineers Benefit from Corrosion-Resistant Pipes?

Many industries that work in harsh environments choose composite corrosion-resistant pipes because they have so many advantages.

● Internal and external corrosion resistance

Composite pipes don’t rust easily on the inside or outside, so you don’t have to pay for expensive repairs and replacements when the material wears out.

● Smooth Inner Surface

The smooth inside of composite pipes cuts down on friction, which makes them more efficient at moving water. This means that less energy is needed to pump, which lowers costs.

● Lightweight and Simple to Install

Composite pipes are much lighter than metal pipes, which makes them easier and faster to move and put in place. This cuts down on both labor and installation costs, especially in places that are hard to get to.

● Long Lifespan

These pipes last a long time, often more than 50 years (Market Research Future), which means they are reliable for a long time and don’t need to be replaced as often.

● No coatings or cathodic protection needed

Composite pipes don’t need coatings or cathodic protection systems like metal pipes do. This makes maintenance easier and cheaper.

● Lower OPEX than metals

Composite pipes cost less to operate (OPEX) than metal pipes because they need less maintenance, use less energy, and last longer.

Applications of Corrosion-Resistant Pipes

Corrosion-resistant pipes are achieving such a place among these modern pipelines with the highest rate of resistance to aggressive conditions, including high pressure or temperature. Here’s how they work properly in each section of piping systems:

Oil & Gas Industry

In the case of offshore and onshore oil and gas pipelines, they mainly require a resistance pipe that can handle hot fluids and is resistant to UV exposure at the same time. Below are three use cases of the GRP family in the oil and gas industry:

- Produced water needs a pipe with good resistance to corrosive material like GRE, which is commonly used in oil and gas pipelines around the world.

- Corrosion-resistant pipes like GRVE have a perfect impact on firewater systems due to their high thermal stability and resistance to chemicals and high-temperature fluids.

- Lastly, the transmission of hydrocarbons is highly reliant on the GRE pipes. This matter can change the material a little bit to add more thermal resilience.

Petrochemical & Refinery

In chemical processing, consider that the presence of vinyl ester can change the game in the transmission of acids and alkalis.

Also, in highly aggressive sites, GRVE pipes with the highest rate of corrosion-resistance among all their alternatives can be used for extremely acidic and alkaline fluids.

For more moderate yet corrosive acids, the case of GRV pipes can be useful, which have lower prices compared to GRVE and fit the use case.

Industrial Process Piping

There are three cases for industrial pipelines, including the chemical plants, fertilizer plants, and cooling systems. Each may require its specific pipe.

- For instance, the case of fertilizer systems with acids and alkali fluids, GRV pipes, counted as top choices, shows no corrosion at all.

- Or, in the cooling water systems with a lower risk of corrosion, GRP pipes are the best and the most cost-effective choice that can tolerate this environment.

Water & Wastewater

In the case of water transmissions, due to the lower number of corrosive fluids, GRP pipes are used that require less maintenance over decades of piping life.

But if you’re planning for a sewer system, the case of a GRV pipe may be more useful and can last over 50 years with no corroded area included.

Get the Best Corrosion-Resistant Pipes for Your Projects

After all the way we’ve been through, we understand how proper corrosion-resistant composite pipes are for various applications. For corrosion-resistant composite pipelines (GRVE, GRE, GRV), trust LineCore Pipes Group. At LineCore Pipes Group, we provide you with a wide range of GRP families just designed based on your specific project demands. For more information or to place an order, visit pipelinecoregroup.com. Let us help you choose the right pipe for your needs!

FAQs

1- What are corrosion-resistant pipes made of?

Made from composites (GRVE, GRE, GRV, GRP), thermoplastics (HDPE, PVC), or corrosion-resistant alloys (stainless steel, CRA).

2- Are composite pipes strong enough to handle high pressure?

Yes, composite pipes like GRVE and GRE can handle pressures of up to 50 bar or more, depending on the type.

3- Can composite pipes be used offshore?

Yes, GRE pipes are often used in offshore oil and gas pipelines because they don’t rust easily.

about

The Author

Farshid Tavakoli is a seasoned professional in engineering and international trade. Holding degrees in Electrical Engineering, Mechatronics, and a Doctorate in Business Administration (DBA) from the University of Lyon, he also has a strong background in industrial automation and production line technologies.

For over 17 years, he has led an international trading company, gaining deep expertise in commercial solutions tailored to industrial needs. With more than 8 years of active involvement in infrastructure development, he specializes in the supply of electromechanical equipment for water and wastewater treatment plants and transfer projects.

Together with comapny expert team, he now provides consultancy and integrated solutions for sourcing and implementing complex infrastructure projects across the region.