In the modern era of piping systems, GRP pipes, as the most-used pipelines among composite pipe families, include various jointing methods to match every application in location conditions. GRP pipes and their fittings are made of glass fibers and a resin matrix, which improves strength and resistance to cracks at the same time.

This post dives deep into GRP pipe jointing methods, installation requirements, testing, and further inspections for long-term performance under high pressures or external loads.

How to classify GRP Pipe Jointing Methods by Their Strength or Flexibility?

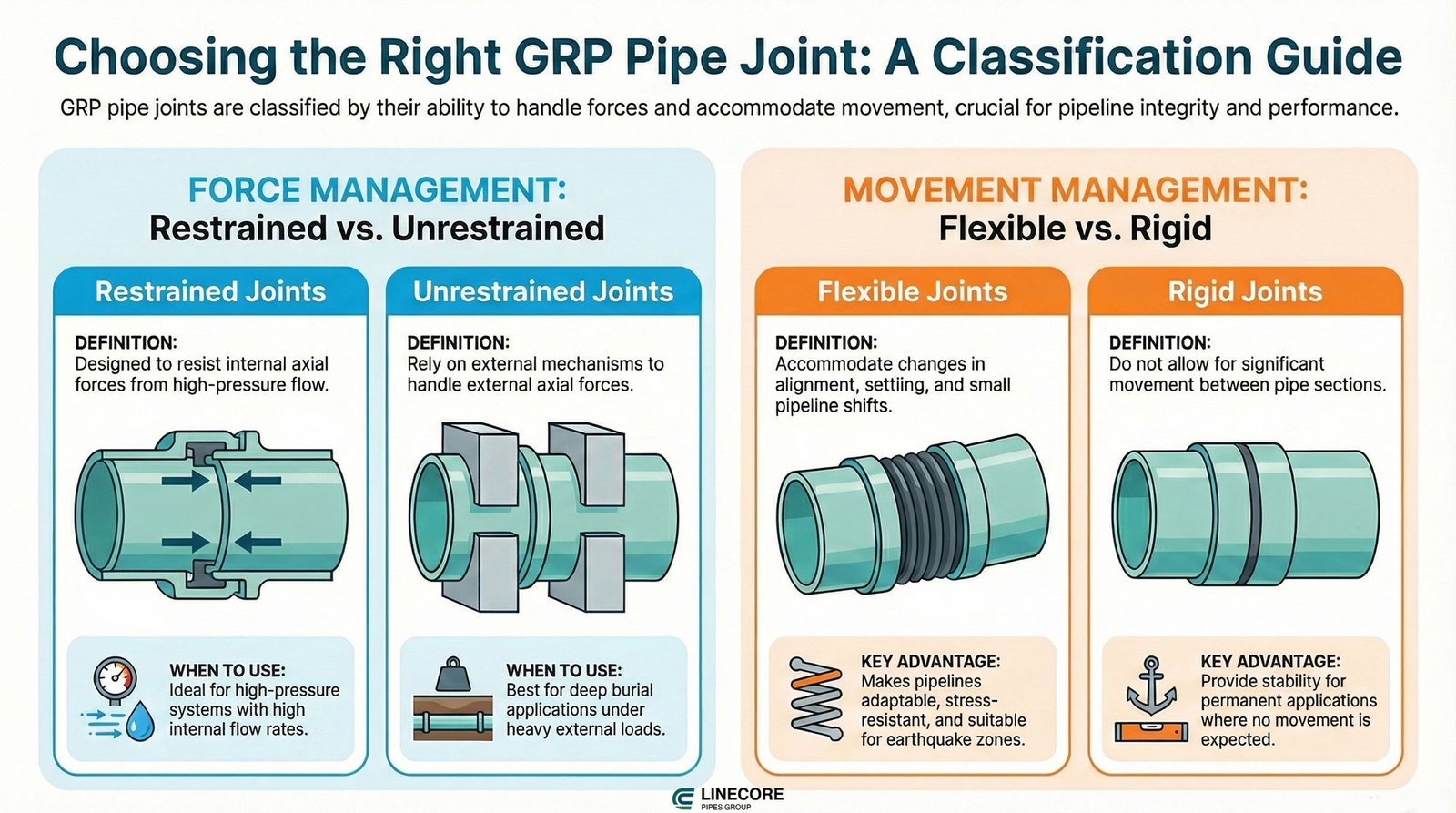

GRP pipe jointing methods are classified by the way they handle movements and forces. There are two main types: restrained or unrestrained joints, and flexible or sturdy ones.

1. Restrained vs. Unrestrained Joining Methods

Restrained joints are designed in a way that may resist axial forces and internal pressures of flows, while unrestrained joints are those that can handle axial forces via their external mechanisms.

- Restrained Joints: Ability to handle internal axial forces

- Unrestrained Joints: Ability to handle external axial forces

Then, choose restrained joints when it comes to high-pressure systems with high rates of flow, and choose unrestrained ones for deep burial and heavy loads.

2. Rigid vs Flexible GRP Joints

Besides pressure resistance of joints in GRP pipes, they might also be flexible or rigid enough for differential conditions. For instance, flexible joints are used in earthquake-resistant pipelines. Check the points below for more specific use cases of flexible or rigid joints.

- Flexible joints can handle changes in alignment or small shifts in the pipeline, while rigid joints don’t allow much movement.

- Flexible joints are better for places where the earth or pipes settle, since they can handle deflection. (Source: Scribd)

- Flexible couplings make pipelines more adaptable and less stressful, while rigid joints make permanent applications more stable.

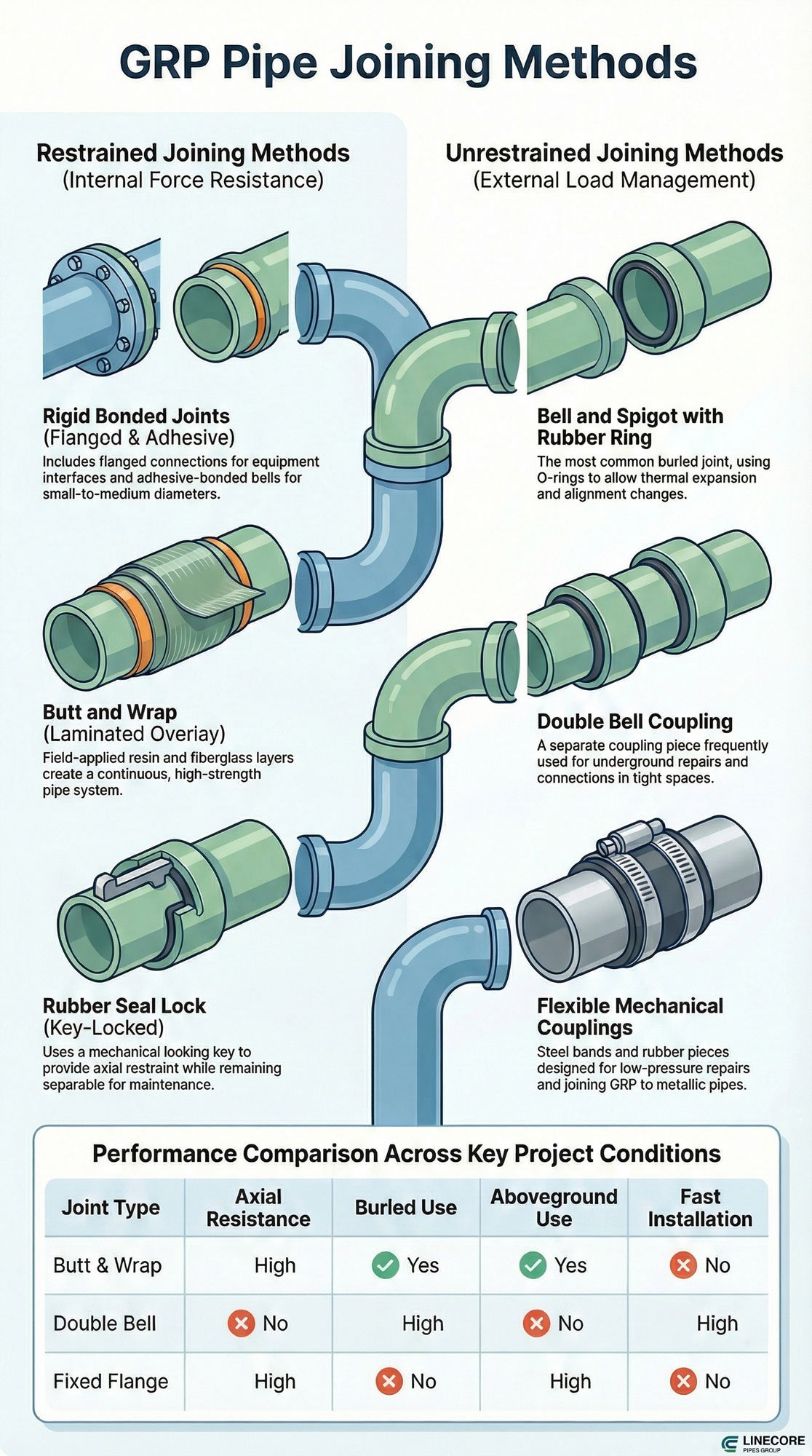

What Are the Restrained GRP Pipe Joining Methods?

Restrained joints are mainly known for their internal pressure resistance. This section goes through all GRP pipe jointing methods that cover inner pressure that can be changed by pressure, temperature, or flow rates.

1. Flanged Joint Method

Flanged joints are used for restrained and sturdy connections with no need for extra blocks, which can be used for aboveground installations, stations, and equipment interfaces.

There are two main types of this joint, such as fixed ones and stub end ones:

- Fixed GRP Flange Joint: Flat-face flange design for even gasket compression. There are flat rubber gaskets and O-ring gaskets to choose from. Good for moderate to high pressures, with diameter limits set by the stiffness of the flange and the load on the bolt.

- Stub End with Flange Joint: FuturePipe notes that the steel backing flange lets the part turn to make it easier to line up. Makes it easier to install, take apart, and keep up with. Often used close to valves, pumps, and connections between steel pipes.

2. Butt and Wrap (Laminated Overlay) Joint

By gluing GRP layers over aligned pipe ends in the field, this joint makes a completely continuous pipe system. The mentioned glue can be epoxy, which itself makes pipes resistant to temperature or corrosion.

❖ How Joints Can Transfer Fluids Under Heavy Loads?

The laminated composite layers carry axial and hoop loads.

❖ How Butt and Wrap Works

To connect pipes via the butt and wrap method, try the steps below to ensure a reliable yet flexible connection.

- To get the ends of the pipe ready, roughen the surface, clean it, and line it up perfectly.

- The external lamination process adds layers of resin and fiberglass all the way around.

- Internal lamination is added for large diameters or high-pressure classes under external loads.

- Lastly, Curing and Restraint, you need temporary support until the full cure is done.

3. Bell and spigot with adhesive joint

Structural adhesives are used in adhesive-bonded joints to make a strong, non-flexible connection between pipe sections.

Rigid Bonded Joint Principle

The adhesive moves axial and hoop stresses across the joint.

Types of Adhesive Joints:

- Tapered bell and tapered spigot

- Straight spigot and straight bell

- Straight spigot and tapered bell

Diameter Limits: Usually, only small and medium diameters are allowed.

4. Rubber Seal Lock Joint (Key-Locked Joint)

This joint is used when it comes to elastomeric sealings or a mechanical locking system that keeps it from moving along the axis while still being able to be taken apart.

Bell & Spigot with Elastomeric Seals vs. Locking Key Mechanism

Keeps things from leaking when they’re under pressure, while the mechanism of locking keys relies on the connection of a stronger key into grooves to stop axial damaging forces.

Rubber Seal Joints Advantages

Rubber gaskets or sealed key-locked joints can be used to handle internal forces, while they are able to resist external forces too.

- Axial Restraint Performance: Able to handle all of the internal pressure forces

- Separable Advantages: You can take it apart, look at it, and replace it without cutting the pipe.

In summary, These joints (All Restrained joints) reduce the requirements for extra blocks or anchors. (ScienceDirect)

What Are the Unrestrained GRP Pipe Joining Methods?

Once you get along with restrained jointing methods, it’s time to get to know unrestrained methods. This section goes deep into the external axial forces, which require tough handling of heavy loads upside down or upside down the pipelines.

5. Bell and Spigot Joint with Rubber Sealing Ring

These pipes, which include Bell and Spigot Joint, have a rubber ring to seal them. This is the most common type of joint for buried GRP pipes. It makes a good seal and lets you move around a bit.

- The joint has a socket that was made in the factory and a spigot end that is exactly the right shape.

During assembly, a rubber O-ring is squeezed to make a tight seal that won’t leak. Also, the pipe can move along its length to deal with changes in temperature (Scribd). Each joint can bend a little, which helps fix small alignment problems or ground movement.

6. Double Bell Coupling Joint

Double bell coupling joints use a separate coupling piece to make installation easier. The pressure inside the pipe pushes the rubber seals inside the coupler tightly together. Points to consider:

- This joint lets you change the length more easily and makes it easier to line up pipes when you install them.

- People often use these joints underground to fix things, add new sections, or make connections when there isn’t much room.

7. Flexible mechanical couplings

Mechanical flexible couplings can be used for a lot of things, but they are mostly used for repairs or connections that don’t need to be strong. What to point out when selecting mechanical couplings:

- A combination of rubber pieces and steel bands

- For low- to medium-pressure systems

- Usage: for temporary designs between GRP and metallic pipes

- Cannot resist axial forces properly in high-pressure flows

Comparison of GRP Pipe Joining Methods

Once we discussed all GRP pipe jointing methods, we should compare them to figure out which suits our location conditions better. Check the table below first, and points after that.

| Design / Project Condition | Fixed Flange | Stub End + Loose Flange | Butt & Wrap | Adhesive Bonded | Rubber Seal Lock | Bell & Spigot (RRJ) | Double Bell Coupling | Mechanical Coupling |

|---|---|---|---|---|---|---|---|---|

| Axial Thrust Resistance Required | ✔✔✔ | ✔✔✔ | ✔✔✔ | ✔✔✔ | ✔✔✔ | ✖ | ✖ | ✖ |

| Buried Installation | ✖ | ✖ | ✔ | ✔ | ✔✔ | ✔✔✔ | ✔✔✔ | ✔ |

| Aboveground Installation | ✔✔✔ | ✔✔✔ | ✔ | ✔ | ✔ | ✖ | ✖ | ✔ |

| High Internal Pressure | ✔✔✔ | ✔✔✔ | ✔✔✔ | ✔ | ✔✔ | ✔ | ✔ | ✖ |

| Large Diameter Pipeline | ✔✔ | ✔✔ | ✔✔✔ | ✖ | ✔✔ | ✔✔ | ✔✔ | ✖ |

| Ground Settlement / Seismic Movement | ✖ | ✖ | ✖ | ✖ | ✔ | ✔✔✔ | ✔✔✔ | ✔✔ |

| Fast Installation Required | ✖ | ✔ | ✖ | ✔✔ | ✔✔ | ✔✔✔ | ✔✔✔ | ✔✔✔ |

| Ease of Disassembly / Maintenance | ✔ | ✔✔✔ | ✖ | ✖ | ✔✔ | ✔ | ✔ | ✔✔ |

| Low Installation Skill Dependency | ✔✔ | ✔✔ | ✖ | ✖ | ✔ | ✔✔✔ | ✔✔✔ | ✔✔ |

| Repair / Tie-In Suitability | ✖ | ✔ | ✖ | ✖ | ✔ | ✔ | ✔✔✔ | ✔✔✔ |

A. Restrained vs Unrestrained Joints

Restrained joints are resistant to axial forces in internal cases with no need for blocks, while unrestrained joints can be used in underground pipelines to neutralize external damage.

B. Rigid vs Flexible Joint Performance

Rigid joints are used for more permanent use cases with low risk of cracking or vibrations, while flexible pipes can withstand deformation under seismic zones.

C. Field-Executed vs Factory-Controlled Joints

According to BHEL, field-executed joints depend on workmanship and site conditions. Factory-controlled joints are used for higher consistency and reliability.

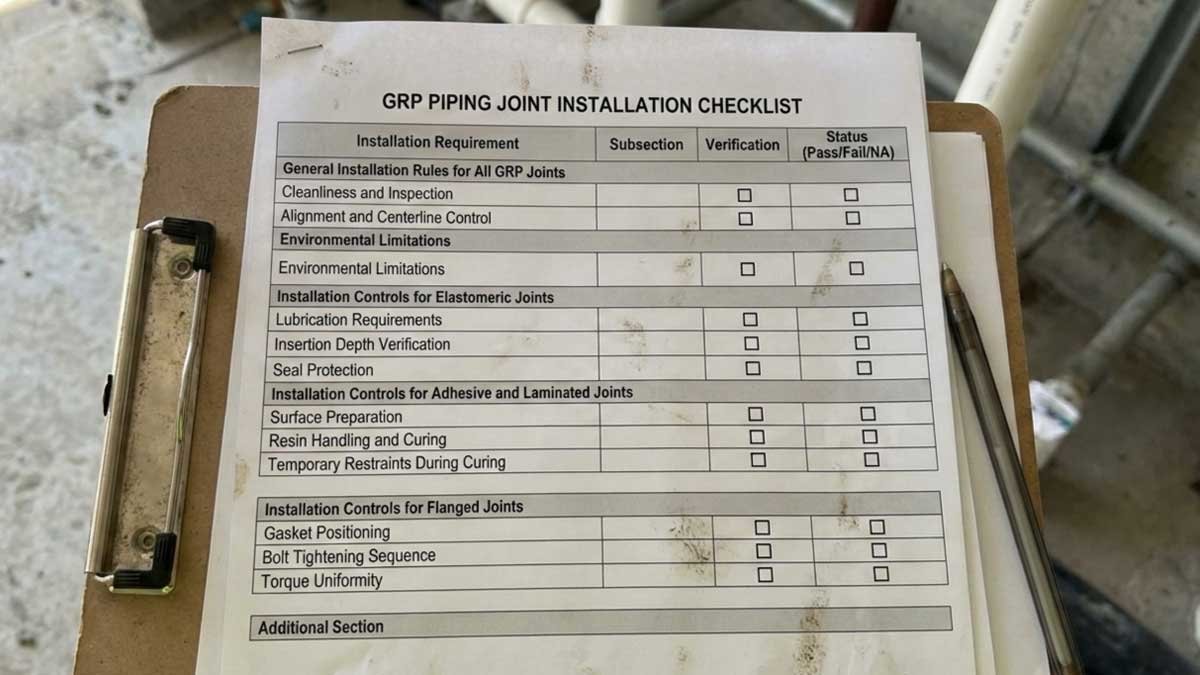

Installation Requirements for GRP Joining Methods

A correct choice of jointing method shows itself in the case of the installation process. To achieve a reliable piping system that lasts for decades, it’s required to follow such guidelines.

● General Installation Rules for All GRP Joints

Firstly, inspect all pieces like pipe ends and jointing sections to be cleaned. Then, pipes must be aligned (centerline). Installation must be controlled based on the manufacturer’s limitations for materials.

● Installation Controls for Elastomeric Joints

These considerations include lubricants for pipes in hard-to-access sites. The final depth should be measured, and protective sealing can be helpful for rocky soils.

● Installation Controls for Adhesive and Laminated Joints

Check adhesive bonding, the required amount of used adhesive, and then check that the curing process is going on properly.

● Installation Controls for Flanged Joints

This is for flanged types and requires uniform curing. Also, check the correct gasket positions and tighten bolts.

Now, you can use the checklist below for your installation process as a built-in QC section.

Allowable Movements and Tolerances by Joint Type

Each GRP jointing system is designed to be used for a specific situation with variable movement levels that pipeline layout, external loads, and ground conditions affect the final choice.

- Angular Deflection: Flexible connections can handle a limited rotation rate, while rigid ones can tolerate heavy pressures with low capacity if deflection.

- Axial Movement: Unrestrained joints can be used under high-risk axial forces, while restrained ones can be used for harsher displacement.

- Settlement: Flexible joints are better choices for places with a risk of vibration and load stresses to reduce these dilemmas within the whole pipeline.

Testing and Inspection of GRP Pipe Joints

Testing and inspections are inevitable for pipelines, which avoid further problems caused by installation or the wrong jointing method.

- Inspections: Visual inspection including cracks, misalignment of pipes and joint sections, or any damage in outer body pipes.

- Hydrostatic Testing: Tests joints and walls for any evidence of cracks or leakage in jointing areas based on ASTM E1003.

- Leakage Criteria: There is an acceptable rate for leakage that must be considered if maintenance is required.

Considerations of the GRP Joining Method

To select a reliable pipeline and its jointing method that lasts for decades with low maintenance cost, it’s needed to consider several points such as:

- The amount of internal pressure and axial thrust will decide if you need restrained or unrestrained joints.

- The size of the pipe and the pressure class affect the type of joint that can be used, especially for laminated and adhesive systems.

- The environment where the installation takes place, like whether it is buried or above ground, affects the movement allowances and thrust control strategy.

- Finally, check if flexibility or restraint is needed based on how much you expect the ground to settle or expand in hot areas, and how much seismic activity there will be.

Typical Applications of Each GRP Joining Method

GRP pipes, due to their perfect specs, are top choices in various applications. Here we bring you a table showing what method to take for each use case:

| Use Case | Recommended Methods |

|---|---|

| Water Transmission | Flanged, Butt and Wrap |

| Sewer/Drainage | Bell and Spigot, Flexible Couplings |

| Fire Protection | Flanged, Rubber Seal Lock |

| Industrial/Chemical | Butt and Wrap, Flanged |

| Desalination/Marine | Flanged, Adhesive Bonded |

| Underground Systems | Double Bell, Flexible Couplings |

| High-Pressure Systems | Flanged, Butt and Wrap |

Common Failures in GRP Pipe Joints + Solutions

All methods may show a flaw, as GRP pipe joints can fail. Here’s how to avoid them:

A. Improper Joint Selection

Check the table in the application or comparison section to avoid wrong selection.

B. Poor Installation Practices

Follow proper alignment, cleanliness, and torque guidelines for resin curing.

C. Seal Damage Failures

Prepare the pipe’s surface for both the handling and installation processes, which may affect the whole system.

FAQs

1- Can GRP joints be used underground?

Yes, with Double Bell Couplings and Mechanical Flexible Couplings.

2- How do I prevent seal damage during installation?

There are protective covers for the installation process to avoid damage, such as cuts and scratches.

3- What is the impact of poor installation on GRP joints?

If pipes are installed incorrectly, they may fail due to cracks, leakage, or joint failures.

about

The Author

Farshid Tavakoli is a seasoned professional in engineering and international trade. Holding degrees in Electrical Engineering, Mechatronics, and a Doctorate in Business Administration (DBA) from the University of Lyon, he also has a strong background in industrial automation and production line technologies.

For over 17 years, he has led an international trading company, gaining deep expertise in commercial solutions tailored to industrial needs. With more than 8 years of active involvement in infrastructure development, he specializes in the supply of electromechanical equipment for water and wastewater treatment plants and transfer projects.

Together with comapny expert team, he now provides consultancy and integrated solutions for sourcing and implementing complex infrastructure projects across the region.