To chill the whole neighborhood instead of wasting tons of energy, a district cooling system can pave the way. As a smart solution for buildings to get rid of running their own AC units, they can easily place underground pipelines to pump the cold water from a central point. To avoid emissions through heat leaks and breakdowns, a well-installed cooling piping system keeps the efficiency for decades.

Check the post below for the best pipe types for the district cooling system, the jacking options, and other beneficial components. Stay sharp till the end!

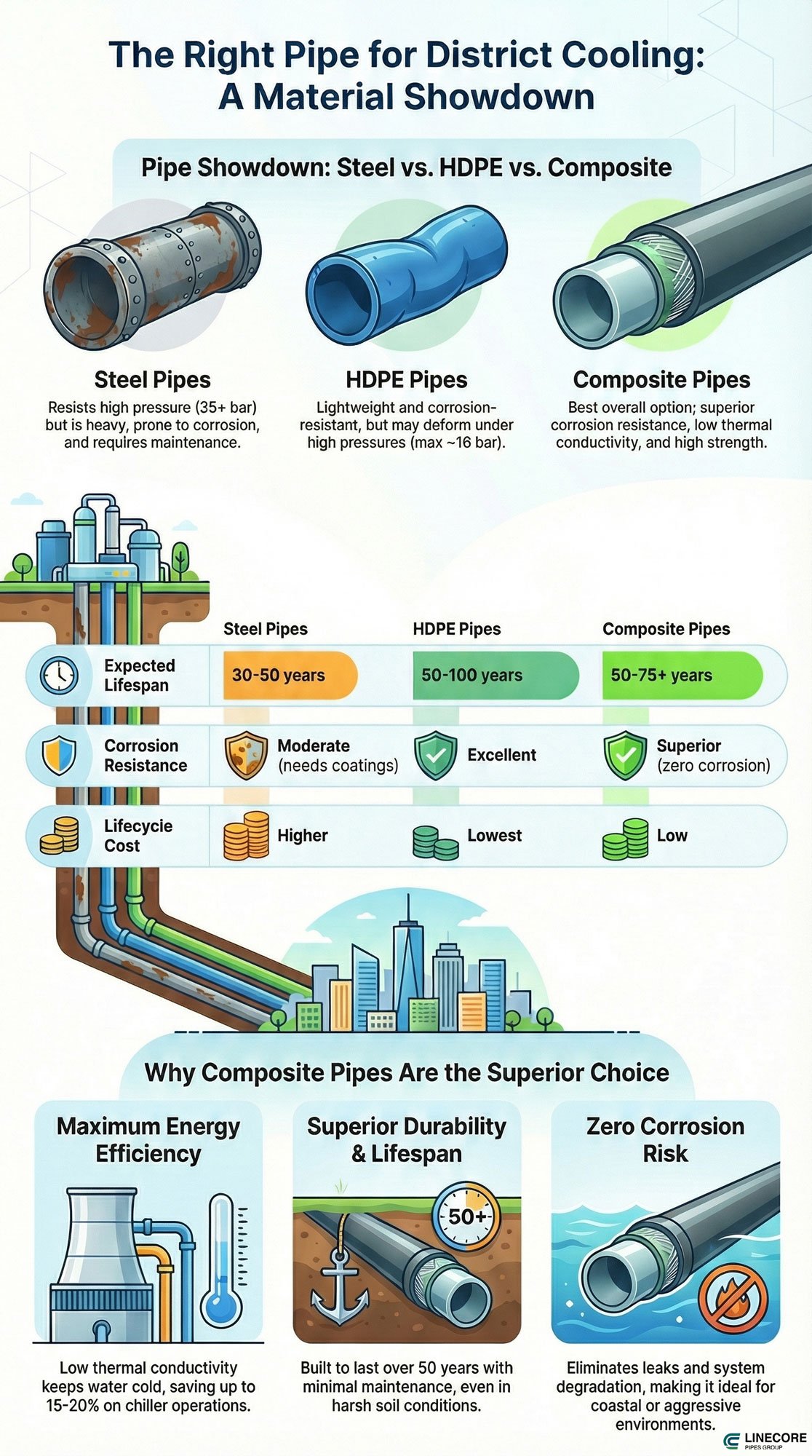

Pipe Types Used in District Cooling Applications

District Cooling Pipes Infographic (Source: pipelinecoregroup.com)

A durable district cooling system requires pipes with low heat absorption that have no impact on the chilled water. This cooling is covered by chillers that support the pipelines. There are three most-used pipelines for this matter, such as composite pipes. HDPE ones and steel pipes.

Steel Pipes: Pressure Handling

In the cases of carbon or stainless-steel pipes, they resist under high-pressure systems up to 25+ bar in large diameters and long lengths in main transmission lines. This long length gets them into transportation problems, though.

- Point: They are very heavy and require extra protective coatings, besides the continuous maintenance costs.

HDPE Pipes: Lighter than Steel

High-density polyethylene (HDPE) pipes are lightweight, flexible, and corrosion-resistant in harsh environments. Their jointing systems are so reliable that they show no leak over time in secondary lines or in the trenchless installations.

- Light Point: They may crack or deform under high pressures, as they can tolerate more moderate pressures up to 16 bar in distribution lines.

Composite Pipes: The Best Option

Fiberglass-reinforced composites (GRP, GRE, GRV) are such lightweight pipes that have no reaction in corrosive environments. Their low thermal conductivity and smooth inner surface make them energy-effective choices in multiple use cases like district cooling systems.

- Super Point: Due to their various jointing types and high strength-to-weight ratio, they are the best options for underground installations.

Comparison of Steel, HDPE, and Composite Pipes

Check the Table below to compare these three pipelines for the chilled water uses:

| Parameter | Steel Pipes (Carbon/Stainless with Coatings) | HDPE Pipes (PE100) | Composite Pipes (GRP/GRE/GRV) |

|---|---|---|---|

| Material Composition | Carbon steel or stainless with epoxy/cement lining | High-density polyethylene | Fiberglass reinforced with polyester/epoxy/vinyl ester resin |

| Typical Diameter Range | 100-2000mm+ | 20-1600mm | 300-4000mm |

| Max Pressure Rating | 25-40+ bar | 10-25 bar (PN10-25) | 16-50+ bar (custom engineered) |

| Temperature Range | -20°C to 120°C (with insulation) | -40°C to 60°C | -50°C to 140°C (GRE higher) |

| Thermal Conductivity | High: 45-50 W/m·K (requires thick PU insulation) | Moderate: 0.4-0.45 W/m·K | Low: 0.25-0.5 W/m·K (best inherent insulation) |

| Density/Weight (DN500 example) | Heavy: 100-200 kg/m | Light: 20-40 kg/m | Medium: 30-60 kg/m |

| Corrosion Resistance | Moderate (needs coatings/CP; vulnerable to pitting in saline soils) | Excellent (inert to chemicals/water) | Superior (resin barrier; zero corrosion even in aggressive environments) |

| Chemical Resistance | Fair (linings degrade over time) | Excellent (resists chlorides, acids) | Outstanding (GRE for harsh chemicals; no scaling) |

| Hydraulic Roughness (Hazen-Williams C) | 120-140 (initial; decreases with corrosion) | 150 (smooth, stable) | 150 (permanent smoothness) |

| Expected Lifespan | 30-50 years (with maintenance) | 50-100 years | 50-75+ years |

| Flexibility/Stiffness | Rigid (high modulus ~200 GPa) | Highly flexible (modulus ~0.8 GPa) | Semi-rigid (10-30 GPa; customizable) |

| Joining Method | Welding, flanges (skilled labor) | Heat fusion (leak-proof, fast) | Adhesive bells/spigots, laminations |

| Installation Speed/Cost | Slow/high (heavy equipment, welding) | Fast/low (lightweight, trenchless options) | Medium (specialized but fewer supports) |

| Maintenance Requirements | High (coating inspections, CP monitoring) | Minimal (no corrosion) | Minimal (no painting/CP needed) |

| Lifecycle Cost (50 years) | Higher (due to maintenance/replacements) | Lowest overall | Low (high initial but long life) |

| Recyclability | High (steel recyclable) | Excellent (fully recyclable) | Moderate (resin recovery possible) |

| Seismic/Impact Resistance | Good (ductile) but heavy | Excellent (flexible) | Very good (anisotropic strength) |

● Pros and Cons of Steel, HDPE, and Composite Pipes

Steel Pipes: Strong enough to resist under heavy loads but weak in corrosive conditions, and requires protective coatings.

HDPE Pipes: Light and resistant to corrosion and flexible (>500% elongation), but they fail in unstable thermal conditions or under external loads. (Source: ResearchGate)

Composite Pipes: GRP, GRV, and GRE each show specific superiority in terms of corrosion, pressure, or temperature resistance, while their initial cost may be a bit high, but they make up for the overall cost.

Overview of Composite Pipes for District Cooling

Composite pipes make the transportation of chilled water easier than ever. Whether in cities or industrial applications, they stay like the first day with no corrosion and save energy.

What Are Composite Pipes?

These pipes are mainly made of fiberglass and resin. The resin type can change to add some special properties to pipes or just improve those aspects.

- GRP: Glass Reinforced Plastic (uses polyester resin)

- GRV/GRVE: Glass Reinforced Vinyl Ester/Epoxy

- GRE: Glass Reinforced Epoxy

How Are Composite District Cooling Pipes Made?

They are made by various manufacturing methods like filament winding, centrifugal casting, hand lay-up, and pultrusion, each of which can shape pipes in changing lengths and structures.

For instance, hand lay-up is used for fitting and joint production. Or, centrifugal casting makes a smooth inner surface that decreases the cost of pumping energy.

Differences Between GRP, GRE, GRV, and GRVE

The differences among these three pipes come from their resin matrix type: polyester, vinyl ester, and epoxy.

- Polyester resin is used to make GRP pipes. Not too expensive. Good for basic resistance. Not for the harshest cases.

- Epoxy resin is used to make GRE pipes. They are highly strong and can handle temperatures up to 120°C. Best at fighting corrosion and high-pressure systems.

- Vinyl ester resin is used to make GRV and GRVE pipes. The GRVE has been improved by adding epoxy resin. Balances resistance to acid. Strong against impacts. Less expensive than the GRE.

Choose based on project needs. GRE for heat, GRV for chemicals, and GRP for general uses.

Why Composite Pipes Are Increasingly Preferred

Composite pipes are one of those modern solutions for various piping systems in all climates and conditions. This preference stems from their superior aspects and characteristics.

- They last over 50 years.

- Cuts cost long-term.

- Low heat transfer keeps water cold.

- Saves energy in urban networks.

- Up to 20-30% efficiency gain.

- Lighter than steel.

- Installs faster.

- Lowers carbon footprints.

Technical Advantages of Composite Pipes in District Cooling

Composite pipes are perfect for district cooling systems in an aggressive environment. They don’t show corrosion easily and help save energy.

Corrosion Resistance

These pipes don’t need supplementary linings since they can handle acids, salts, and other things that eat away at them. They are built to last in soils that are damp or harsh.

They eliminate leaks and help systems survive longer, which makes them work better than steel in coastal environments.

Low Thermal Conductivity

They don’t allow heat to pass through them very effectively, which keeps the water cooler while it’s being carried and cuts down on energy losses in the pipes.

As noted in ScienceDirect, plastic composites are less conductive than metals, which could save 15–20% on chiller operations.

Toleration under High-Pressure and Temperature Systems

They can take pressures of up to 25 bar, while GRE types can handle temperatures of up to 120°C. This gives them the strength to handle pump surges while still being flexible.

Durability and Cost-Effectiveness

They are light and easy to put together, which keeps expenses down. They are also made to last for more than 50 years with lower maintenance requirements.

They are generally a better option than steel, and they are also better for the environment because they don’t generate as much trash and pollution.

Insulation and Jacketing Options for District Cooling Pipes

The case of chilled water, unlike other use cases, requires reliable insulation and jacketing due to the importance of water temperature.

- Pre-Insulated Pipes: The wrap of foam around the pipe, known as pre-insulated pipe, helps the insulation to get faster. This action helps pipes to lose less heat and makes chillers work less to save energy. (Source: +GP+)

- PU/PIR Insulation: Polyurethane (PU) and Polyisocyanurate (PIR) are used for composite carrier pipes that manage the thermal properties by their nature and are lightweight in underground piping systems.

- HDPE and GRP Outer Jackets: To protect both pipe and insulation, an outer jacket of HDPE or GRP can be used to keep pipes away from damage like UV light, corrosion, and physical impacts.

Leak Detection Compatibility

Modern district cooling systems include leak-detecting devices in the insulation around the pipes. This feature makes it possible to find leaks early, which means that maintenance can be done on time and system breakdowns can be avoided.

Standards and Certifications for Composite Cooling Pipes

Take a glance at the table below to check all relevant standards for composite pipes in the district cooling pipes, from their material and designs to further testing.

| Standard | Category | Description |

|---|---|---|

| ISO 1167 | Testing | Hydrostatic testing for pressure resistance. |

| ISO 1402:2021 | Hydrostatic testing of hoses and plastics. | |

| AWWA C600 / C605 | Hydrostatic pressure testing for pipes. | |

| ISO 8301 | Measurement of thermal conductivity. | |

| ISO 8521 | Mechanical testing for GRP pipes. | |

| ASTM D2992 | Testing fiberglass pipe strength and impact resistance. | |

| ASTM D2996 | Design/Manufacturing | Fiberglass pipe durability testing for physical properties. |

| ISO 9001 | Manufacturing | Quality management systems for manufacturing. |

| ASTM F1282 | Design | Design and material specifications for fiberglass pipes. |

| ISO 4427 | Design/Material | Polyethylene pipes for water supply (material specifications). |

| ISO 14692 | Design/Material | Design and material requirements for GRP pipes in the petroleum and gas industries. |

What To Consider When Installing Composite Pipes In The District Cooling Systems?

To make sure that composite district cooling pipes last a long time and work well, they need to be installed correctly.

- Moving and Handling: When moving composite pipes, you need to be careful not to break them. They should be kept safe and away from things that could hurt them.

- Jointing Methods: Adhesive bonding, lamination, and couplings are all ways to join things that are strong and don’t leak. Lamination makes seams stronger, whereas adhesives are often employed to make them smooth. (Source: Scribd)

- Trench Design and Burial: The trench should be built so that the pipes won’t get damaged when the ground moves. To keep pipes secure, they need to be deep enough and have protective layers.

- Field Joint Insulation: To keep heat from escaping, field joints need to be insulated. To keep the pipe working properly and save energy, you should use certain materials that match the pipe’s thermal qualities.

Applications of Composite Pipes in District Cooling Projects

Due to the shining aspect of GRP, GRV, and GRE pipes’ characteristics, such as thermal stability and flexibility, they are used in the district cooling systems without a doubt.

1. Large Urban Cooling Networks

In cooling systems under the whole city, composite pipes can be shaped in wide lengths, and an easy installation process.

2. Industrial Cooling Systems

Composite pipes are the best option for high temperatures that don’t change the fluid temperature as well.

3. Mixed-Use Developments & Smart Cities

In modern cooling systems infrastructures like residential, commercial, or public use cases, composite pipes are a green choice with minimal waste and pollution.

How to Select the Right Pipe Material for District Cooling

When it comes to selecting a pipeline for your district cooling system, there are multiple points you might consider. Check the aspects below to make sure that your selection was to the point.

- GRP (Glass Reinforced Plastic) works for general cooling applications that include less initial cost and handle more moderate surrounding conditions.

- GRE (Glass Reinforced Epoxy) is best for aggressive environments that contain harsh chemicals like acids and alkalis due to its superior corrosion resistance.

- GRV (Glass Reinforced Vinyl Ester) and GRVE (Glass Reinforced Vinyl Ester) pipes are the best options for high-pressure and high-temperature conditions.

Finally, to make the selected pipeline real and installed in the location, financial evaluations must be considered. Then, check the prices and the project demands and site conditions for the most reliable selection, which lasts over decades.

Choose Reliable District Cooling Pipes Today

For high-quality district cooling pipes and composite pipes, trust LineCore Pipes Group for reliable supply and expert solutions. Contact us at info@pipelinecoregroup.com for more information and to get started on your next project.

FAQs

1- Which is better: GRP or GRE pipes?

GRP for general uses in less aggressive sites and GRE for high-temperature uses.

2- Why are composite pipes preferred over steel?

Composite pipes show no corrosion in the district cooling systems and are lighter for burial and installation.

3- Can composite pipes handle high pressure?

Yes, they are highly resistant to pressure and heavy external loads due to their high strength-to-weight ratio.

about

The Author

Farshid Tavakoli is a seasoned professional in engineering and international trade. Holding degrees in Electrical Engineering, Mechatronics, and a Doctorate in Business Administration (DBA) from the University of Lyon, he also has a strong background in industrial automation and production line technologies.

For over 17 years, he has led an international trading company, gaining deep expertise in commercial solutions tailored to industrial needs. With more than 8 years of active involvement in infrastructure development, he specializes in the supply of electromechanical equipment for water and wastewater treatment plants and transfer projects.

Together with comapny expert team, he now provides consultancy and integrated solutions for sourcing and implementing complex infrastructure projects across the region.