Glass Reinforced Plastic (GRP) pipes are a composite combination of glass fibers and a thermosetting resin matrix to shape a lightweight, corrosion-resistant, and durable pipeline. This structure allows GRP pipes to be used in water supply, chemical processing, or irrigation plants. Standards are the core of an efficient GRP piping system; they are more than just paperwork. Thus, for a consistent performance over decades, GRP pipe standards such as ISO 10639 or AWWA C950 are crucially needed.

Whether you’re an engineer or a project manager about to select the right GRP pipe for your infrastructure, this article guides you to identify the required standards for each parameter of GRP pipes.

What Are International GRP Pipe Standards?

To keep the consistency in the quality and safety of GRP pipelines, global standards provide an outline for various applications from manufacturing to testing and installation process. Below, standards like ISO, ASTM, AWWA, and European ones are defined:

ISO Standards: the insurance for water supply and sewage systems

ISO standards are mainly used in sewage and water supply systems for perfect performance. For instance, ISO 10467 covers the use of GRP pipe for low-pressure filtration and sewage pipelines, while ISO 10639 focuses on the proper design of GRP pipes in drinking water GRP pipe specifications.

ASTM Standards: High-Pressure and Sewage Systems

ASTM standards such as ASTM D3262 support chemical resistance in non-pressure stormwater or sanitary sewage systems.

ASTM D3517 indicates the right pressure tolerance and hoop strength via hydrostatic testing for water systems, and ASTM D3754 recommends the tight stiffness class and joint methods for industrial applications with corrosive fluids.

AWWA Standards: Hydrostatic Testing

One of the crucial standards in GRP pipes is to test the stiffness and leaks via hydrostatic testing for high-pressure water and chemical transmissions, including all diameter sizes (25mm to 4,000mm) and pressure class ratings (50 to 450 psi).

British and European Standards

In European standards, with unsaturated polyester resin, BS EN 1796 guarantees that GRP pipes for water supply systems, with or without pressure, satisfy standards for the transmission of fluids and potable water.

In contrast, GRP pipes in drainage and sewerage systems are covered by BS EN 14364, which places a special emphasis on chemical resistance and strength for underground applications, such as culverts.

Classification Parameters in GRP Pipe Standards

GRP pipe standards determine some parameters and their ranges to allow engineers to select the proper pipeline that meets their project demands. Characteristics like pressure class, stiffness class, and diameter range shape the finish design:

Pressure Classes (PN)

Show the highest internal pressure in bars that a GRP pipe is capable of withstanding (PN 6, PN 10, PN 16, up to PN 40, for example). A PN 16 pipe, for instance, is designed to endure 16 bar of pressure in offshore piping systems or drinking water GRP pipe specifications.

Stiffness Classes (SN)

Used for measuring the tolerance of pipes under external loads and heavy traffic for water supply systems in highways, for instance. Also, based on BHEL, it’s quantified in psi, and typical ranges are SN 200, SN 5000, and SN 10000, where the higher the stiffness, the deeper the pipes can be buried.

Diameter Ranges

The Diameter size of GRP pipes varies from DN 100 (100mm) to DN 4000 (4000mm) or more, based on the required flow in water, wastewater, and industrial applications.

Wall Thickness

Can be measured as nominal and actual by design or manufacturing process that influences stiffness and strength of GRP pipes in high-pressure systems with no leaks or degradation through hydrostatic testing (AWWA C950).

Load Categories

Shows how GRP pipes behave in each traffic or non-traffic zone based on last characteristics like stiffness or wall thickness. AWWA M45 or ISO 10465 contains the installation method and jointing types in heavy traffic loads or soft soils.

| Parameter | Definition | Typical Values | Applications | Standards |

|---|---|---|---|---|

| Pressure Classes (PN) | Max internal pressure (bar) | PN 6, 10, 16, 25, 40 | Drinking water, offshore piping | ISO 10639, ASTM D3517 |

| Stiffness Classes (SN) | Resistance to external loads (kPa) | SN 2500, 5000, 10000 | Sewage, traffic zones | ISO 10467, BS EN 14364 |

| Diameter Ranges | Nominal diameter (mm) | DN 100 to 4000+ | Water supply, industrial piping | AWWA C950 |

| Wall Thickness | Nominal or actual thickness | 5–50+ mm | High-pressure sewage | ASTM D3517, BS EN 1796 |

| Load Categories | Traffic vs. non-traffic zones | Traffic, non-traffic | Roads, sewage systems | AWWA M45 |

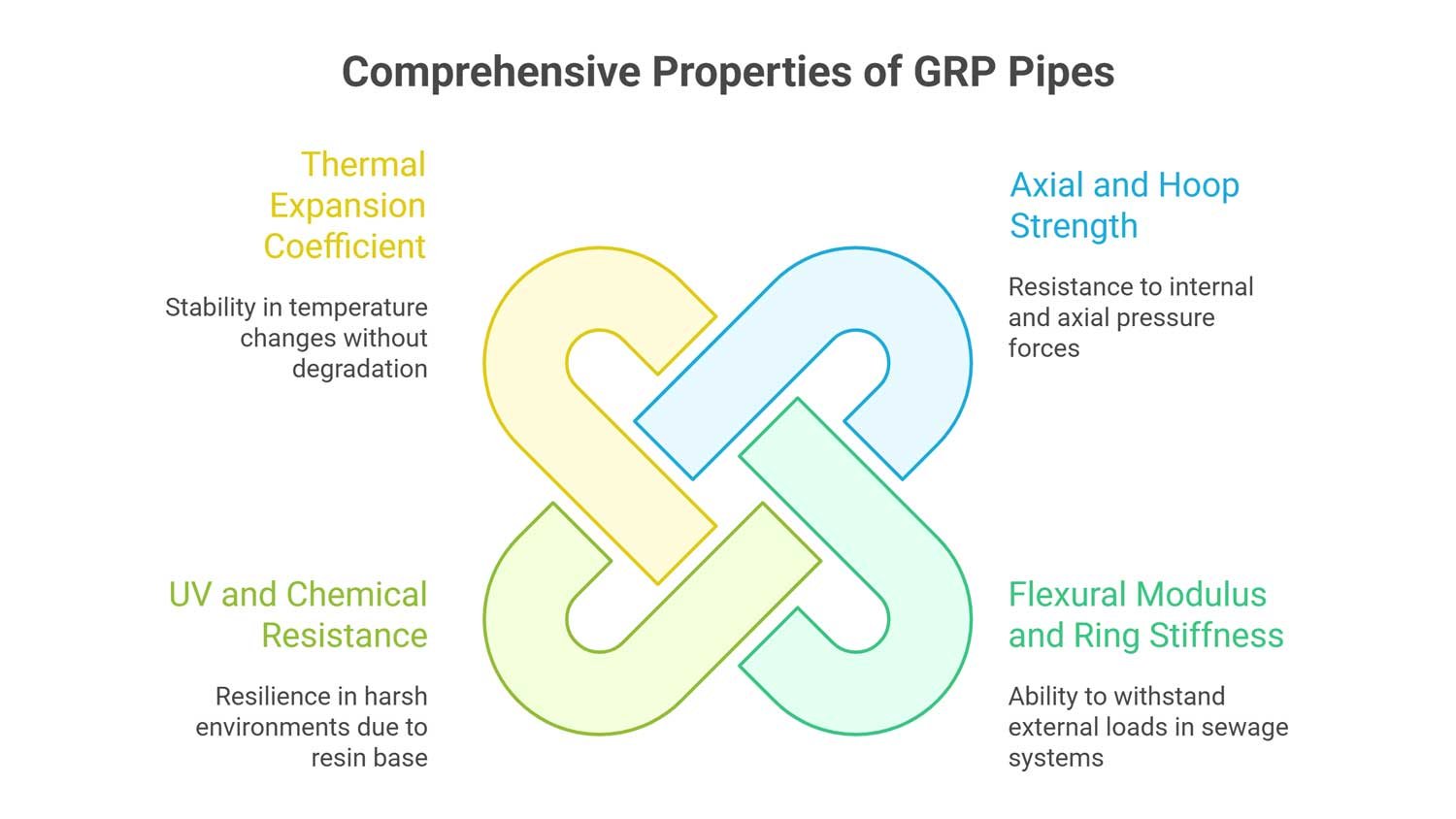

Standardized Mechanical and Physical Properties of GRP Pipes

GRP pipes include numerous properties, showing magnificent performance in harsh environments. International standards outline the required components to create the desired pipeline for water, offshore, or industrial piping projects.

- Axial and Hoop Strength: Based on the ISO 14692 and ASTM D3517, GRP pipes are resistant to internal and axial pressure forces, which are used for offshore plants.

- Flexural modulus and ring stiffness: These properties, which are based on ISO 10467, make GRP pipes a top choice in sewage systems, capable of withstanding external loads.

- UV and Chemical Resistance: According to BS EN 1796, GRP pipes resist in harsh environments via their resin base in chemical processing or irrigation plants.

- Thermal Expansion Coefficient: GRP pipes show no degradation in temperature changing due to this property, per AWWA M45.

Testing Procedures Required by GRP Pipe Standards

GRP pipe standards like ISO 10639 and AWWA C950 work for GRP pipe testing, whether joint tightness or hydrostatic testing for leak prevention and durability over decades.

ISO 14692 and AWWA C950 emphasize hydrostatic pressure testing for GRP pipes to tolerate internal pressures via guarantees of the hoop strength for drinking water and offshore piping.

Tests for degradation and ring stiffness shape GRP pipes in sewage systems in a way to endure external loads and fulfill ISO 10467’s stiffness class (SN) requirements.

As noted in ISO 7432, joint sturdiness testing in jointing methods like socket-and-spigot prevents leaks in water transmission systems. (Source: Scribd)

According to ASTM D3262, impact resistance and flattening tests allow GRP pipes to tolerate handling and external forces in industrial piping.

ISO 14692 highlights that the quality of GRP pipe material for chemical durability in sewage systems should be determined by the following factors: resin matrix, fiber design, and layer thickness.

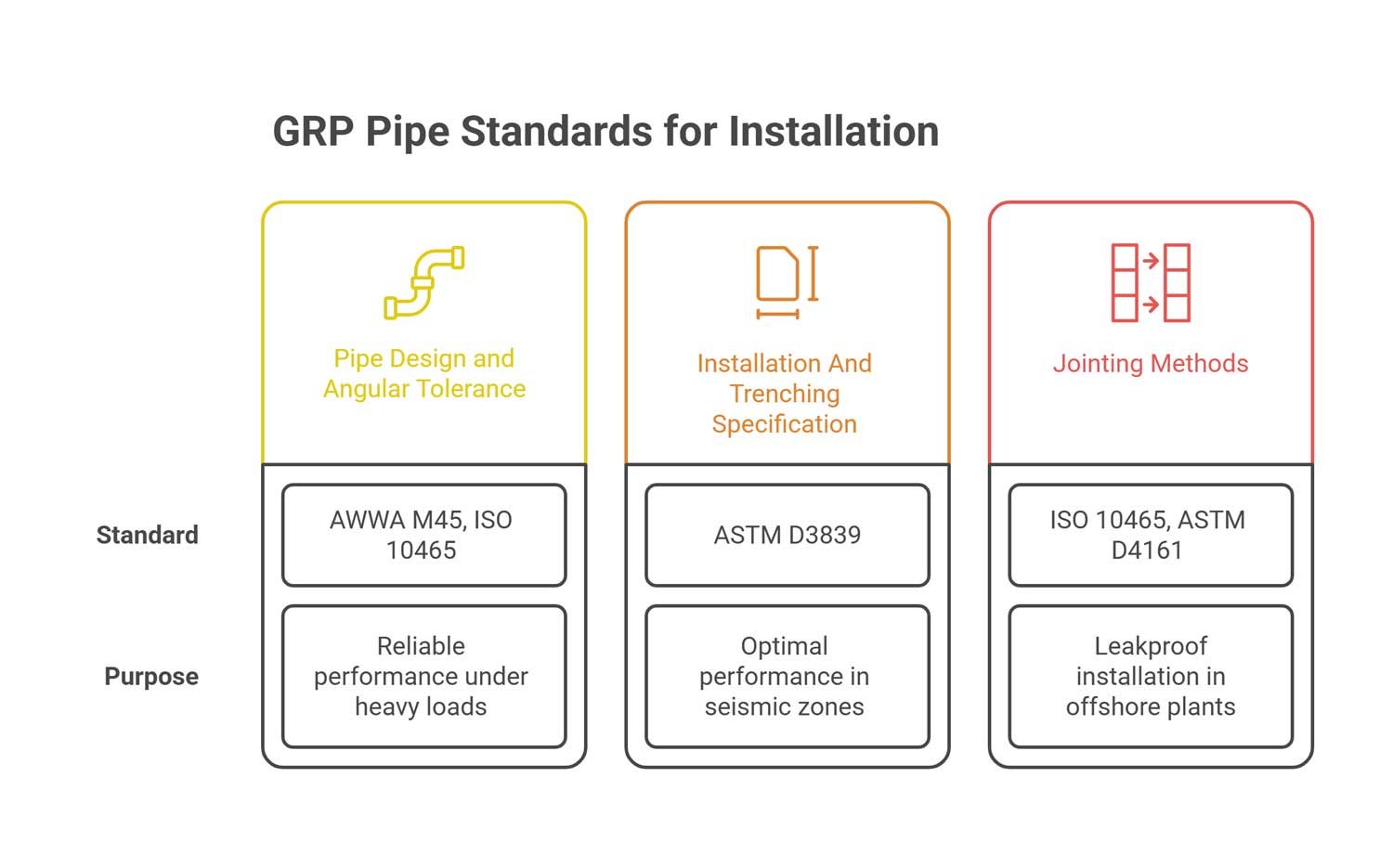

Installation Standards and Field Guidelines for GRP Pipes

For the installation section of GRP pipes, standards are fundamental aspects to avoid leaks and degradation under heavy loads after years of transporting fluids. Below, three central components are defined by their appropriate standards:

- Pipe Design and Angular Tolerance: As stated in AWWA M45 and ISO 10465, for a reliable performance in water supply and sewerage systems, GRP pipes are designed with the proper angular tolerance under heavy loads.

- Installation and Trenching Specification: As per ASTM D3839, GRP pipes act perfectly in seismic zones with the right trenching and bedding in underground installations.

- Jointing Methods: Standards like ISO 10465 and ASTM D4161 help engineers choose the proper jointing method for a leakproof installation in offshore plants through bell and spigot, butt-wrap, or mechanical joints.

Design Criteria Based on GRP Pipe Standards

GRP pipes provide such a unique design that represents their smooth flow, pressure tolerance, and safety factors for long-term performance via standards like AWWA C950 or ISO 10465.

- Hydraulic Parameters: For velocity, flow, and head loss adjustment, AWWA M45 and ISO 10639 balance these factors in GRP pipes for fluid transmission efficiency.

- Structural Loading and Surge Considerations: GRP pipe installation goes through standards like ASTM D3839 and AWWA C950 for the proper trenching in both hard and soft soils, and pressure spike avoidance of GRP pipes in offshore systems.

- Factor of Safety (FOS): For a long-lasting pipeline performance under high external loads in sewage systems, ISO 14692 and ASTM D3754 provide instructions for fatigue design and FOS.

- Sustainable Considerations: As per BS EN 1796 and ASTM D3263, GRP pipes resist in harsh environments and corrosive fluids for decades.

| Design Criterion | Definition | Typical Values | Applications | Standards |

|---|---|---|---|---|

| Hydraulic Parameters | Optimizes flow, velocity, head loss for efficient fluid transport. | Velocity: 1–3 m/s; Head Loss: 2–5 m/100 m | Drinking water, industrial piping | AWWA M45, ISO 10639 |

| Structural Loading | Accounts for burial depth, live loads, soil types to resist forces. | Depth: ≥1.2 m; Load: H-20; Soil Modulus: ≥1.4 MPa | Sewage, traffic zones | AWWA M45, ASTM D3839 |

| Surge and Transient Pressure | Addresses pressure spikes from pumps or valves. | Surge: 1.5–2 × design pressure | Offshore piping | ISO 14692, AWWA C950 |

| Factor of Safety (FOS) and Fatigue Design | Ensures resistance to long-term and cyclic stresses. | FOS: ≥2.0; Fatigue: >10^6 cycles | Sewage systems | ISO 14692, ASTM D3754 |

| Environmental Compatibility | Ensures resistance to corrosive soils/fluids. | pH: 2–12; Vinyl ester resin | Industrial piping | BS EN 1796, ASTM D3262 |

Regional and National Variations in GRP Pipe Standards

GRP pipes follow several standards all around the world to achieve that reliable performance for long-term planning in piping systems. In this section, firstly, the most-used standards are compared via a table, then we’ll explore the standards of India and Germany, and some local required authorities.

Comparison of ISO, ASTM, AWWA, and EN

While EN is used for European chemical durability, ASTM and AWWA focus on U.S. water supply and sewage, while ISO focuses on global marine systems’ performance.

| Standard | Scope | Key Focus | Testing | Applications |

|---|---|---|---|---|

| ISO (e.g., ISO 14692) | Global | Offshore piping, fatigue design | Hydrostatic, fatigue | Offshore, industrial |

| ASTM (e.g., ASTM D3517) | U.S. | Sewage, water supply | Hoop strength, ring stiffness | Sewage, drinking water |

| AWWA (e.g., AWWA C950) | U.S. | Drinking water, installation | Pressure testing, trenching | Water supply, sewage |

| EN (e.g., BS EN 1796) | Europe | Potable water, chemical durability | Joint tightness, chemical resistance | Drainage, water supply |

India and Germany: Must-noticed Global GRP Pipe Standards

- IS 12709: Indian Standard IS 12709, which adapts to the local climate and infrastructure needs with hydrostatic testing, prepares GRP pipes for water supply and sewage in India.

- BS EN vs DIN 16868: Compared to BS EN (British standards), German DIN 16868 uses higher standards for the mechanical joints and thermal expansion of GRP pipes, with an eye for industrial piping durability.

Compliance and Certification Protocols for GRP Pipes

To keep the consistent quality and safety of GRP pipelines, operating strict compliance protocols of GRP pipe standards is crucial:

For instance, through standards like ISO 9001 or ISO 14001, sustainable considerations are included in the pipeline manufacturing and quality insurance.

In Europe, to ensure a durable and standardized pipeline based on BS EN 1796, CE marking with FPC (Factory Production Control) systems is needed.

Moreover, according to the FRPI, Traceability systems evaluate batch numbers and test results for quality assurance in offshore and industrial applications, while independent inspections by TÜV and SGS clarify GRP pipe compliance with ISO 14692, ASTM D3517, and AWWA C950 through testing.

Future Directions in GRP Pipe Standardization

Recent trends of GRP pipes stem from an evolution of technological components in applications like water, sewer, and industrial transmission through standards like ISO 14692 and ASTM D3517 for a durable and eco-friendly GRP pipeline.

- Changes to ISO 7432 improve the performance of GRP pipes and the ways that joints are tested for sewage systems and offshore piping.

- Monitoring innovative pipes refers to the smart GRP pipe with built-in sensors that make it easier to keep an eye on water supply and industrial piping in real time.

- Advanced Materials: For offshore piping and irrigation plants where ocean and high-temperature conditions cause challenges, advanced materials will develop the usage of GRP pipes.

- Standards for Sustainability and Carbon Reduction: GRP pipes follow standards in eco-friendly resin choices for reducing the carbon footprint and improving the recycling process.

Conclusion

Glass-reinforced plastic (GRP) pipes are guaranteed to provide dependable, corrosion-resistant performance for water supply, sewage, and offshore piping by standards such as ISO 14692, ASTM D3517, AWWA C950, and BS EN 1796. In order to ensure safety, efficiency, and compliance over many years, engineers are guided by these standards, which define pressure classes, stiffness, jointing techniques, and chemical durability.

FAQs

1- Why are GRP pipe standards important?

For consistent performance over decades, GRP pipe standards such as ISO 10639 or AWWA C950 are crucially needed.

2- What do ISO standards cover for GRP pipes?

ISO standards mainly used in sewage and water supply systems for a perfect performance.

3- What is the focus of ASTM standards for GRP pipes?

ASTM standards such as ASTM D3262 support chemical resistance in non-pressure stormwater or sanitary sewage systems.

about

The Author

Farshid Tavakoli is a seasoned professional in engineering and international trade. Holding degrees in Electrical Engineering, Mechatronics, and a Doctorate in Business Administration (DBA) from the University of Lyon, he also has a strong background in industrial automation and production line technologies.

For over 17 years, he has led an international trading company, gaining deep expertise in commercial solutions tailored to industrial needs. With more than 8 years of active involvement in infrastructure development, he specializes in the supply of electromechanical equipment for water and wastewater treatment plants and transfer projects.

Together with comapny expert team, he now provides consultancy and integrated solutions for sourcing and implementing complex infrastructure projects across the region.