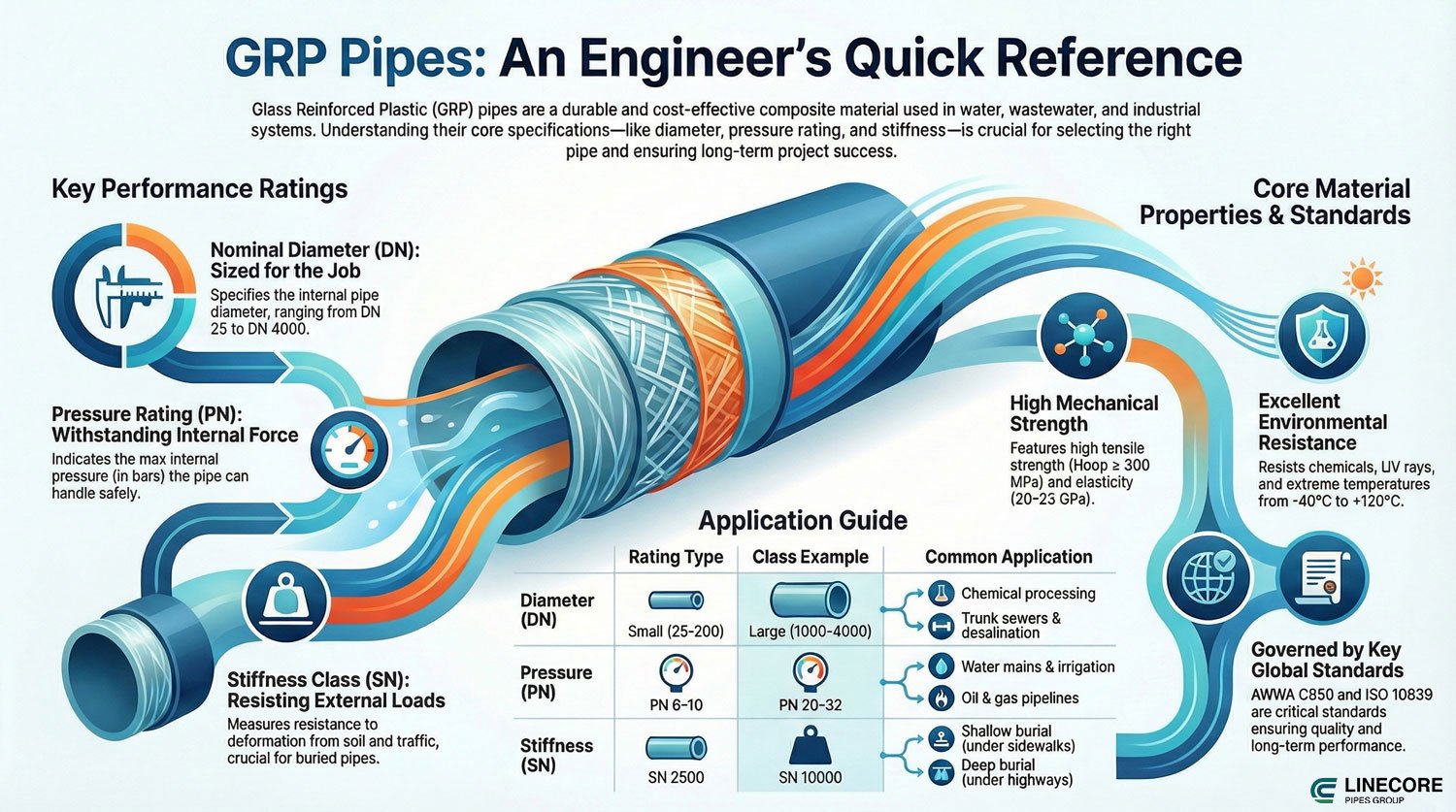

Annually, engineers and contractors face many failed piping projects due to incorrect pipeline selection. GRP pipes, a composite of glass fiber and resin matrix, are widely used in water, wastewater, and industrial systems. Understanding the Glass Reinforced Plastic (GRP) pipe specifications can help you choose the proper infrastructure for your potable water, chemical processing, and oil and gas systems.

In this article, we’ll provide engineers and managers with GRP pipes’ specifications, standards, and applications, helping them with the proper pipeline selection.

GRP pipe specification infographic (source: pipelinecoregroup.com)

Before we dive into the detailed GRP pipe specifications, let’s review them in tables at a glance:

Specification Tables for GRP Pipes

GRP pipes are known as cost-effective and long-lasting pipelines for various applications due to their special specifications. Here are three must-know tables representing characteristics like standardized DN, PN, SN specifications, testing, or chemical properties.

DN, PN, SN specifications per standard

These two tables show how GRP pipes behave in different sizes and how to choose the best pipes based on external loads.

| Nominal Diameter (DN, mm) | Pressure Class (PN, bar) | Stiffness Class (SN, N/m²) |

|---|---|---|

| 200 | 6, 10, 16, 25, 32 | 2500, 5000, 10000 |

| 300 | 6, 10, 16, 25, 32 | 2500, 5000, 10000 |

| 400 | 6, 10, 16, 25, 32 | 2500, 5000, 10000 |

| 600 | 6, 10, 16, 25, 32 | 2500, 5000, 10000 |

| 1000 | 6, 10, 16, 25 | 2500, 5000, 10000 |

| 4000 | 1, 6, 10 | 2500, 5000, 10000 |

Different specifications can be designed based on your project demands.

| Specification | Minimum | Maximum |

|---|---|---|

| Diameter (DN) | 200 mm | 4200 mm |

| Rigidity (SN) | 500 N/m² | 10,000 N/m² |

| Pressure Rating (PN) | 1 atm | 40 atm |

Mechanical and Chemical Property Ranges

Below, through a comprehensive table, effective properties and their possible ranges are defined to create the most reliable pipeline for the piping system’s details.

| Property | Range/Value |

|---|---|

| Hoop Tensile Strength | ≥ 300 MPa (ISO 8521) |

| Longitudinal Tensile Strength | 50-100 MPa (ISO 8513) |

| Modulus of Elasticity | 20-25 GPa |

| Chemical Resistance | High (acids, alkalis, seawater, solvents for vinylester/epoxy) |

| Thermal Conductivity | 0.2-0.4 W/m·K |

| Temperature Range | -40°C to +75°C (polyester), -40°C to +100°C (vinylester), -40°C to +120°C (epoxy) |

| UV Resistance | High with stabilizers or resin-rich external layers |

| Fire Resistance | Self-extinguishing with additives; flame spread index < 25 (ASTM E84) |

| Density | 1.8-2.0 g/cm³ |

| Creep Resistance | High; < 1% deformation over 50 years under constant load (ASTM D2992) |

| Abrasion Resistance | Good; withstands slurry and sediment flow (ASTM D2583) |

- Additional Point: To prevent flames or corrosion, additives following standards like ASTM can reduce the costs by 40% over traditional pipelines like steel or concrete.

Required Tests with Standard References for GRP Pipes

For adapting GRP pipes to international standards for global piping projects, they should be evaluated by several tests and guidelines. Below are the most famous standards for quality assurance.

| Test | Standard Reference |

|---|---|

| Hydrostatic Pressure | ISO 10639, AWWA C950 |

| Stiffness | ISO 7685, ASTM D2412 |

| Hoop Tensile Strength | ISO 8521 |

| Longitudinal Tensile Strength | ISO 8513 |

| Wall Thickness | ASTM D3567 |

| Chemical Resistance | ASTM D2992 (long-term) |

| Visual Inspection | ISO 10639, BS 5480 |

Despite the difficulty of selecting the most-used standard, AWWA C950 is critically used to ensure a long lifespan with no leaks or degradation.

Dimensional Specifications of GRP Pipes

GRP pipes include numerous characteristics that may critically influence their performance in harsh conditions. Their nominal diameter, wall thickness, and pipe length can indicate how transportation and installation should be managed.

Nominal Diameters (DN)

The internal diameter of GRP pipes is called DN, quantified in millimeters, followed by standards like ISO 7370 to create a consistent manufacturing process. As noted in Amiblu, GRP pipes can be produced in various ranges from DN 25 to DN 4000 in both large- and small-scale factories.

- Standard Sizes: DN rates of 25-200 are counted as small ones used in chemical processing and small water systems, DN 300-800 as medium ones in potable water and wastewater pipelines, and DN 1000-4000 are large ones for trunk sewers and desalination plants.

Standard Pipe Lengths

To reduce the gigantic cost of complicated jointing and coupling methods, transportation, and installation of GRP pipes, standardized length via ISO 7370 allows global use for infrastructure projects.

- Typical Lengths: For small to medium DN (DN 25 to DN 600), a length of 6 meters is used. For medium to large diameter sizes (DN 300 to DN 4000), 12-meter pipes reduce the need for extra jointing in water transmission.

Also, lengths up to 18 meters are mainly used for specific applications, though they make transportation challenging in both trenching and trenchless methods.

Wall Thickness and Tolerance Classes

The wall thickness of GRP pipes can be designed based on nominal diameter (DN), pressure class (PN), and stiffness class (SN). For instance, a pipe with DN 200, PN 10, SN 5000 requires ~6 mm, while DN 1000 needs ~15 mm.

- Tolerance classes: Per ASTM D3567, wall thickness must include less than 87.5% of the nominal thickness. However, GRP pipes exhibit perfect resistance to acids. In harsh soils, the outer layer can be reduced, and thicker walls will prevent this issue.

Pressure Ratings (PN) for GRP Pipe Specifications

Pressure ratings, or PN (Nominal pressure), which are essential for applications like chemical and water supply pipelines, specify the highest internal pressure that GRP pipes made via filament winding can withstand.

Standards of PN: According to ISO 10639, PN, measured in bars (1 bar = 0.1 MPa), guarantees safety against surges. Long-term performance is validated by the hydrostatic design basis AWWA C950.

Applications of Different PN Classes: PN1 (gravity sewers), PN6–PN10 (water mains, irrigation, wastewater), PN20–PN32 (oil/gas), and PN40 (high-pressure systems) are typical ratings.

- Use HDB (Hydrostatic Design Basis) data to confirm your choice of PN based on system pressure.

- The PN16-PN32 demand is driving the GRP market’s 2% CAGR growth.

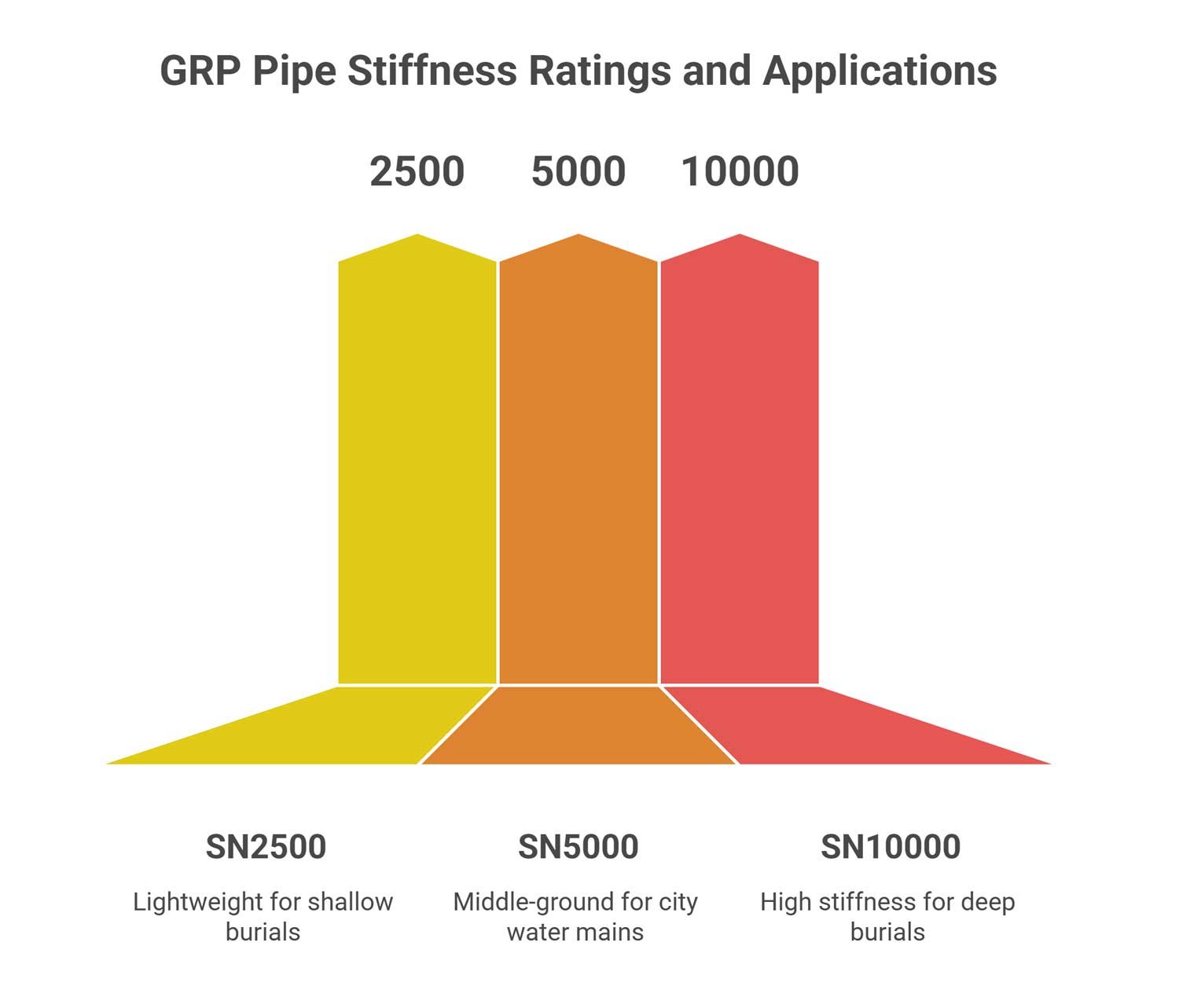

Stiffness Classification (SN Ratings)

The actual meaning of the SN2500, SN5000, and SN10000 ratings (in N/m2) indicates how resistant a GRP pipe is to squishing under external loads. The scoop is as follows:

First, the lightweight property represents how GRP works for shallow burials (0.8–2 m), such as sewers beneath sidewalks, with a SN2500 (2500 N/m²). It can effortlessly flex up to 5%.

Second, the middle-ground pipeline for depths between one and four meters, the SN5000 (5000 N/m2), is ideal for city water mains. It maintains a 3-5% deflection.

Last, for deep burials (2–6 m), such as beneath highways, GRP pipes with the SN10000 (10000 N/m²) are used. Remains extremely rigid with less than 3% flex.

How Well They Perform in Various Soils

The soil type can influence the stiffness of GRP pipes. Since clay soils are solid, light digs can be completed with SN2500; deeper digs require SN5000 or higher. If properly compacted, sandy soils work well with SN5000.

- Use additional support in silt, soft, mushy soils, such as geotextiles, for SN10000.

- For added durability, use vinyl ester resins because acidic soils can erode the pipe’s outer layer.

Standard techniques for stiffness tests

GRP pipes are tested using techniques like ISO 7685 and ASTM D2412 to determine their bending capacity under load (3-5% deflection), ensuring they are more than talk. According to the Water360, they are guaranteed to remain solid with less than 1% sag over 50 years by long-term creep tests (ASTM D2992).

Applicable Standards and Norms of GRP Pipes

For international and local piping projects, standards guide engineers that GRP pipes’ manufacturing process, installation, transportation, and maintenance contain specific requirements. Below, several of the most-used standards for GRP pipes in different applications are explained through a table:

| Standard | Application | Key Specifications |

|---|---|---|

| ISO 10639 | Water supply systems | DN 25–4000, PN 1–40; hydrostatic test at 1.5× PN |

| ISO 10467 | Sewer and drainage systems | Stiffness classes SN 2500–10000; chemical resistance |

| ASTM D3262 | Non-pressure sewer pipes | Wall thickness: 4–50 mm; creep resistance |

| ASTM D3517 | Pressure pipes | Hoop tensile strength ≥ 300 MPa; dimensional tolerances |

| AWWA C950 | Potable water transmission | Covers DN, PN, SN; includes hydrostatic design basis (HDB) testing |

| DIN 16868 | European mechanical standards | Modulus of elasticity: 20–25 GPa; structural performance requirements |

Material Properties of GRP pipes

For a perfect resistance of GRP pipes under external loads and high-pressure systems, balancing these properties below ensures a long-lasting pipeline performance in water supply and chemical processing.

- Tensile Strength: Refers to the internal and axial stresses resistance in high-pressure systems for a durable and leakproof performance. For PN32 pipes, the hoop strength should be more than 300 MPa by adding epoxy or polyester resin base.

- Modulus of Elasticity: Pipe stiffness is determined by the modulus of elasticity (20–25 GPa); lower values permit flexibility, while higher values are appropriate for deep burial (SN10000, for example).

- Chemical Resistance: With a service life of more than 50 years, vinyl ester and epoxy offer exceptional resistance to acids, alkalis, and seawater in chemical environments.

- Thermal conductivity: Compared to steel, GRP pipes have a lower thermal conductivity (0.2–0.4 W/m·K).

- Temperature Range: GRP pipes can tolerate temperatures ranging from -40°C to +75°C for polyester, +100°C for vinyl, and +120°C for epoxy. (Source: What Is Piping)

- UV and Weathering Resistance: GRP is dependable for both buried and exposed installations because UV stabilizers for above-ground use keep strength loss to less than 10% after 1000 hours.

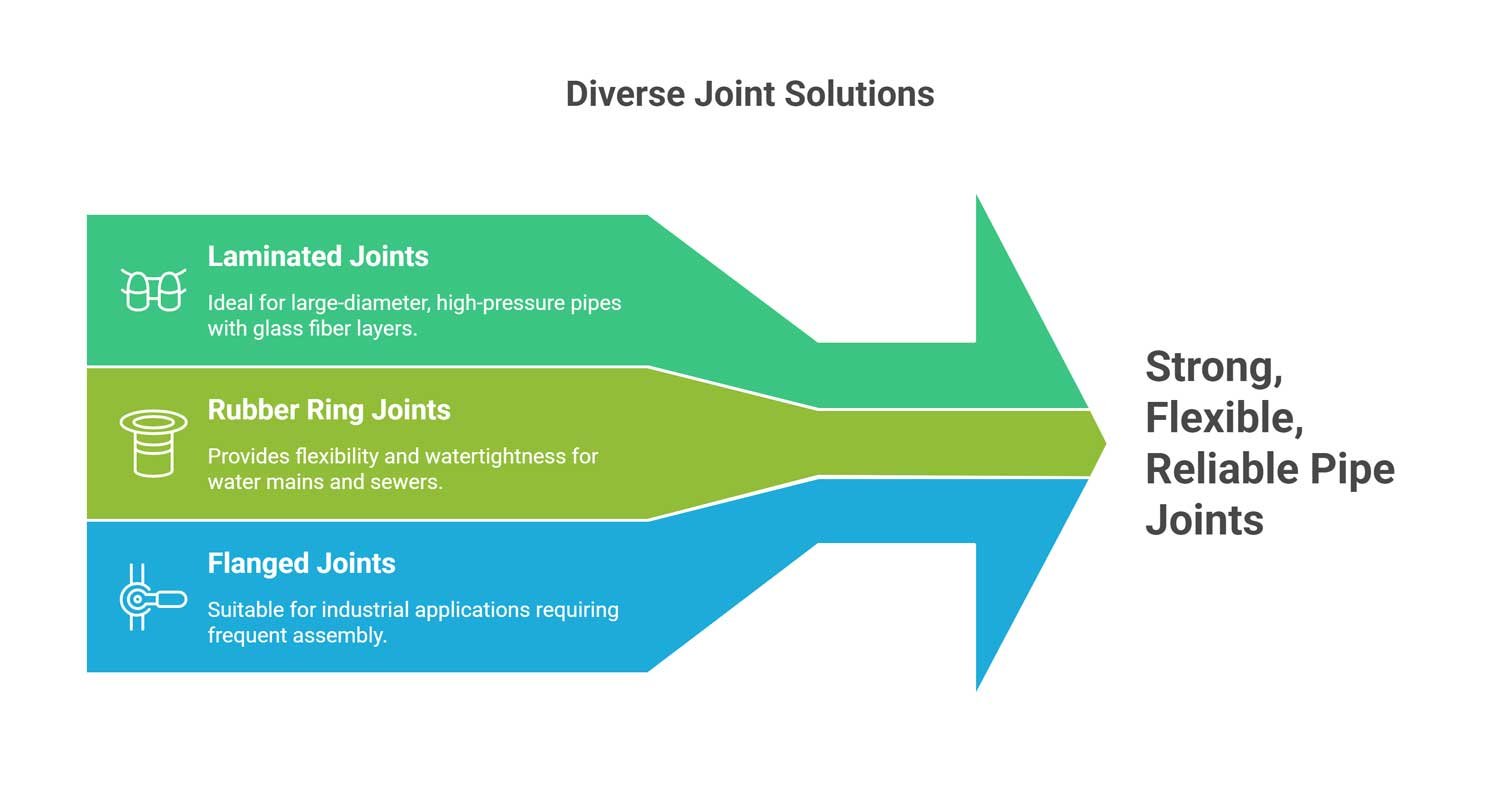

Jointing and Connection Specifications

GRP pipe joints are made to be strong, flexible, and reliable in terms of sealing.

Laminated Joints: Large-diameter (DN1000+) or high-pressure (PN20–PN40) pipes are best suited for laminated joints, which use layers of glass fiber and resin.

Rubber Ring Joints: For PN6–PN16 systems, such as water mains and sewers, rubber ring joints (such as EPDM) provide flexibility and watertightness.

Flanged Joints: Used for industrial applications involving frequent assembly and are made with gaskets and bolts.

Jointing and installation standards

With hydrostatic tests up to 1.5× PN, pressure-tightness is confirmed by standards such as ISO 10639, ASTM D4161, and AWWA C950 to create a long-term leak-free pipeline in all connection types.

GRP Pipe Testing Requirements

GRP pipes go through several essential tests for safe performance and compliance with international standards:

- Testing Hydrostatic Pressure: AWWA C950: Indicates that the pipe won’t leak when internal pressure is applied.

- Stiffness Testing: The ISO 7685: Under external load, stiffness testing verifies the pipe’s rigidity and SN classification.

- Testing for Deflection: The ASTM D2412: Predicts long-term behavior in buried conditions by measuring deformation under load.

- Vacuum Testing: ASTM D2924: Vacuum testing examines a system’s ability to withstand collapse under negative pressure (such as suction lines).

- Testing for Impact Resistance: The ISO 3127: Confirms the pipe’s resilience during installation, handling, and transportation.

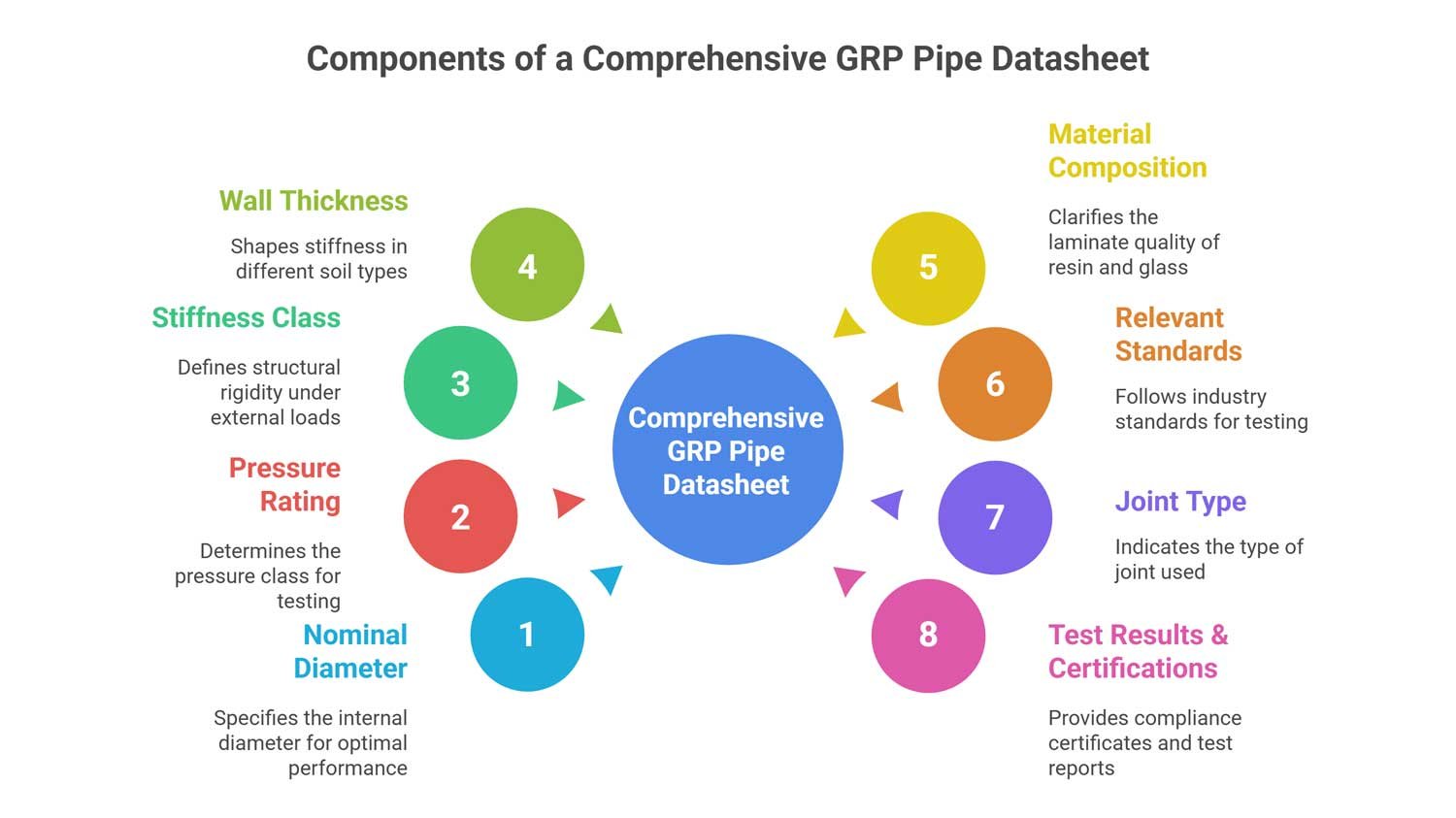

Datasheet and Quotation Essentials: What to Include

It’s necessary to make sure all technical details are included for a quote or when looking over a GRP pipe datasheet. Accurate pricing is supported by this data, which also provides adherence to global standards and project specifications. The following should be included in a thorough GRP pipe datasheet or RFQ:

- Nominal Diameter (DN): Indicates the required internal diameter for optimal results.

- Pressure Rating (PN): To determine the pressure class for further testing.

- Stiffness Class (SN): Defines structural rigidity for buried conditions, under external loads, and heavy traffic.

- Wall Thickness: Incorporate tolerance and nominal values to shape stiffness in different soil types.

- Glass and Resin Types: Clarify the material composition and laminate quality of the resin and glass content.

- Relevant Standards: Follows industry standards like ISO, ASTM, and AWWA for testing and pipe characteristics.

- Joint Type: Indicate if the joint is laminated, flanged, mechanical, or so.

- Test Results & Certifications: Provide compliance certificates and factory test reports.

Final Thought

With their adaptable DN, PN, and SN specifications, GRP pipes provide long-lasting, reasonably priced solutions for industrial, wastewater, and water systems. Engineers can choose pipes with the best tensile strength, stiffness, and chemical resistance by being aware of standards such as ISO 10639 and AWWA C950. Long-term performance is ensured by proper jointing and thorough testing, which lowers project failure rates and supports infrastructure dependability for more than 50 years.

FAQs

1- Why are GRP pipes considered cost-effective for various applications?

GRP pipes are known as cost-effective and long-lasting pipelines for various applications due to their special specifications.

2- What are the standard nominal diameter (DN) ranges for GRP pipes?

GRP pipes can be produced in various ranges from DN 25 to DN 4000 in both large- and small-scale factories.

3- How do standard pipe lengths benefit GRP pipe installation?

To reduce the gigantic cost of complicated jointing and coupling methods, transportation, and installation of GRP pipes, standardized length via ISO 7370 allows global use for infrastructure projects.

about

The Author

Farshid Tavakoli is a seasoned professional in engineering and international trade. Holding degrees in Electrical Engineering, Mechatronics, and a Doctorate in Business Administration (DBA) from the University of Lyon, he also has a strong background in industrial automation and production line technologies.

For over 17 years, he has led an international trading company, gaining deep expertise in commercial solutions tailored to industrial needs. With more than 8 years of active involvement in infrastructure development, he specializes in the supply of electromechanical equipment for water and wastewater treatment plants and transfer projects.

Together with comapny expert team, he now provides consultancy and integrated solutions for sourcing and implementing complex infrastructure projects across the region.